-

Abstract

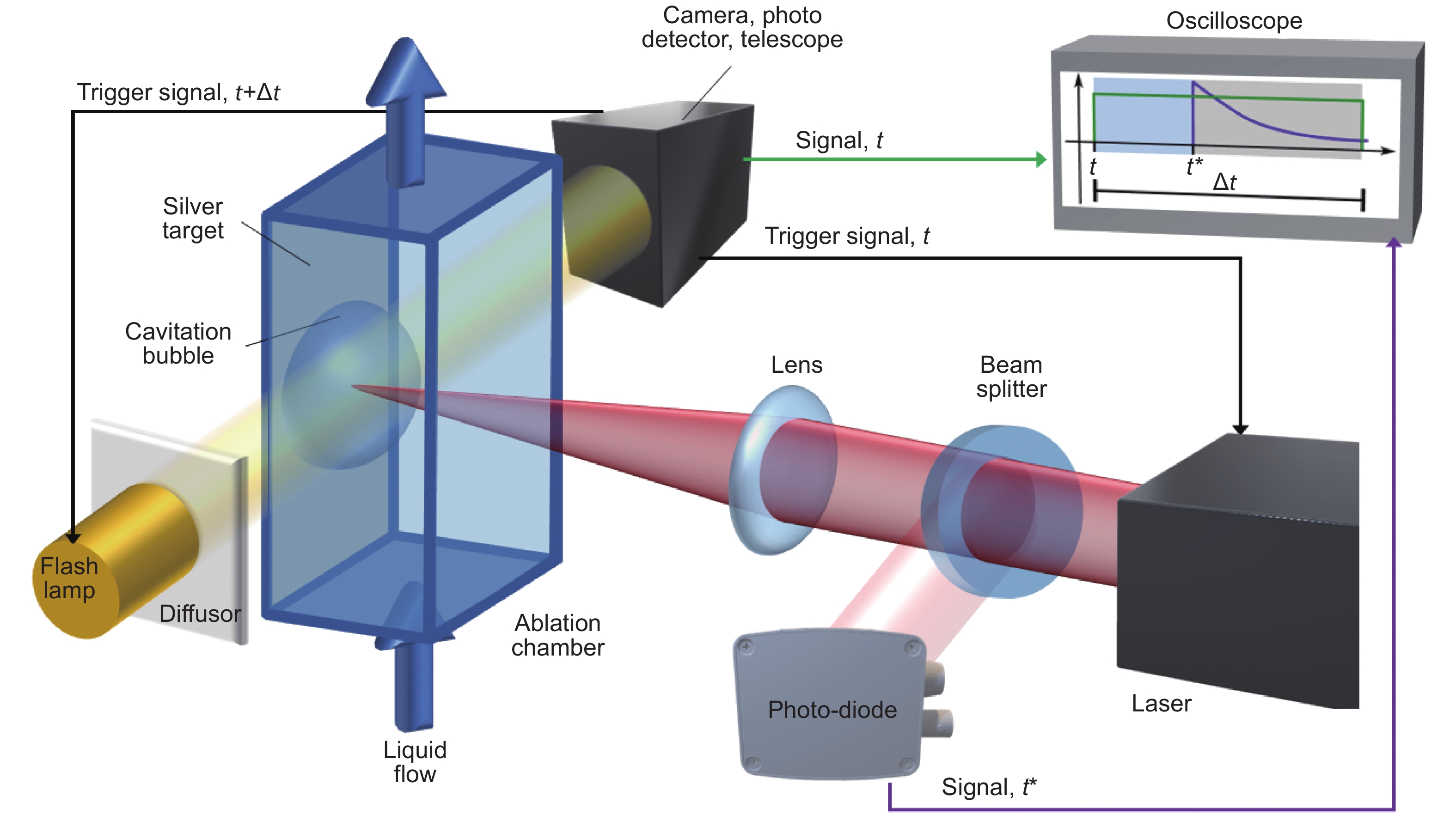

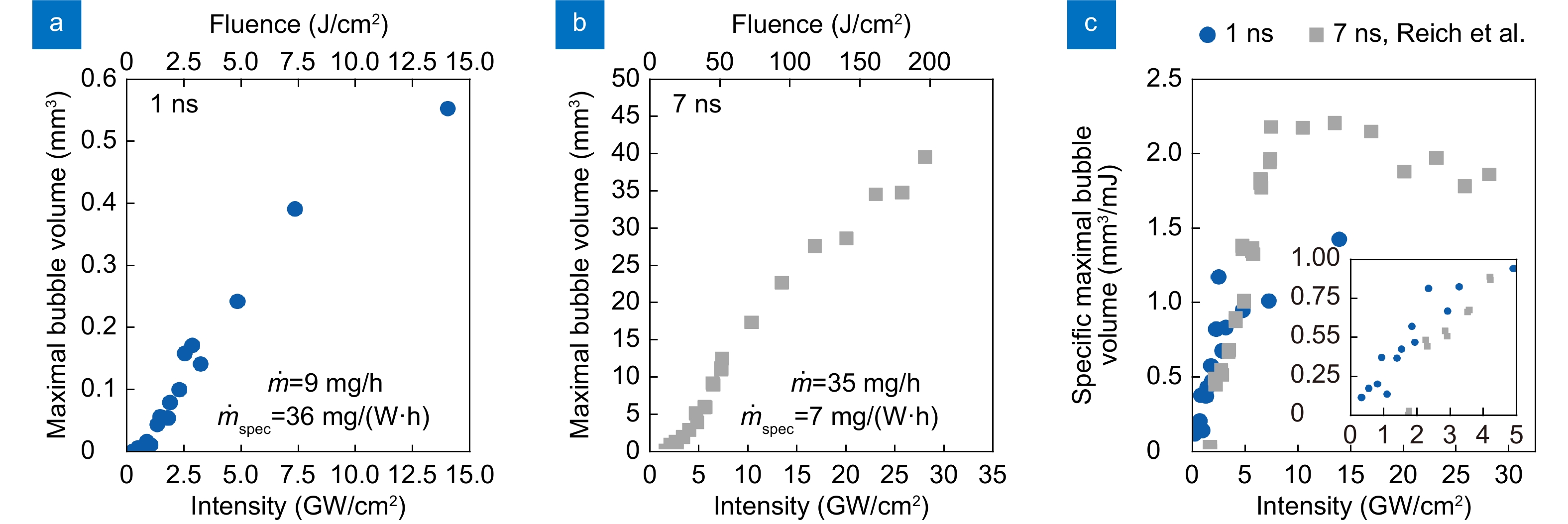

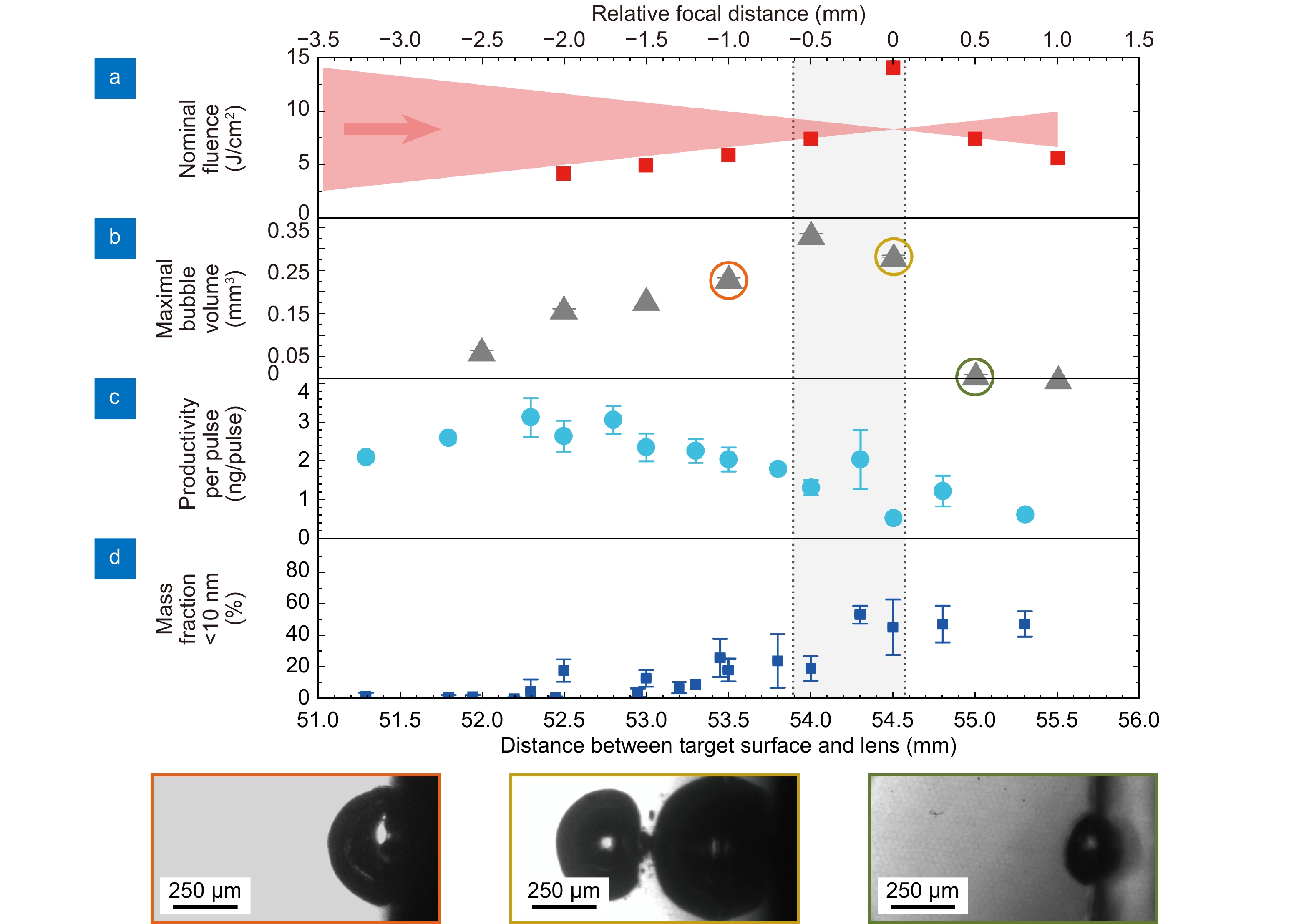

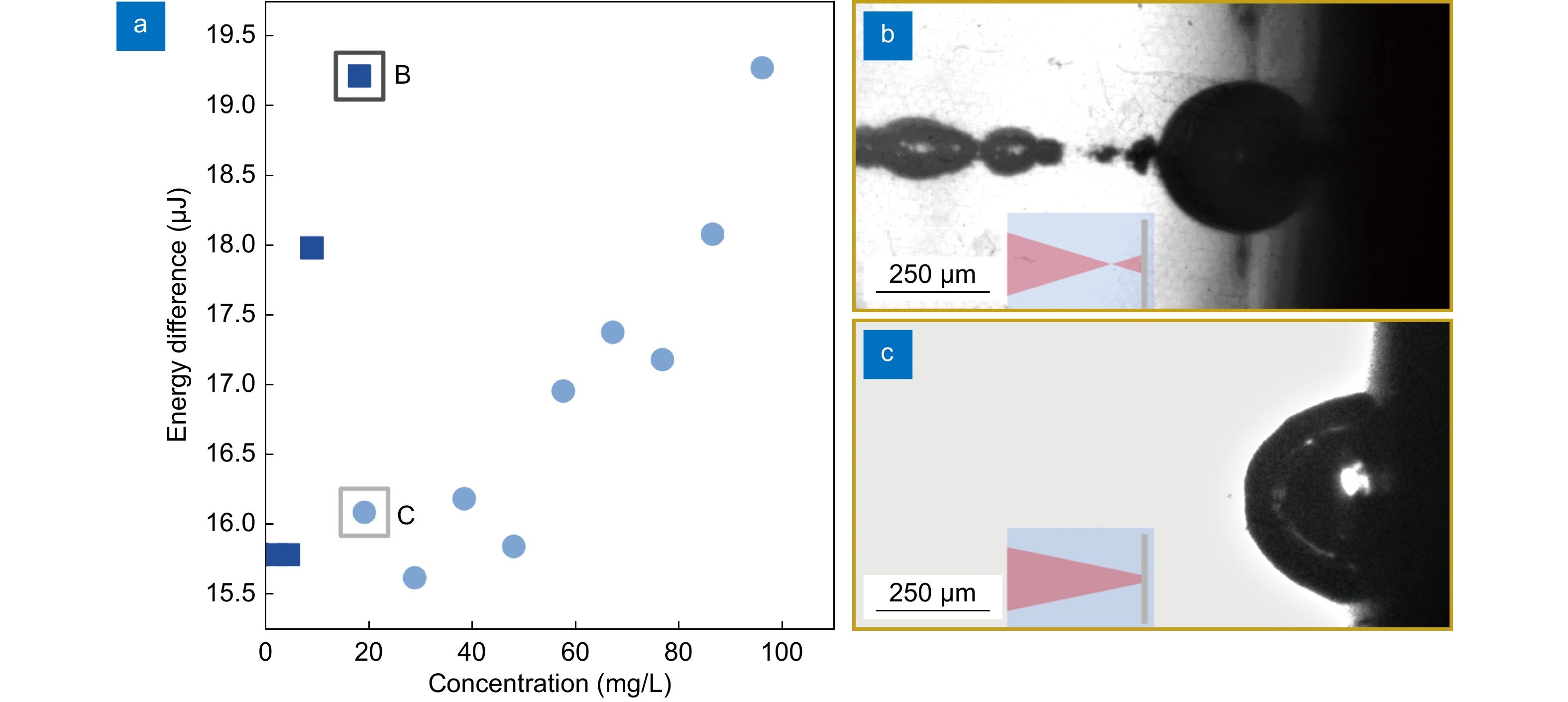

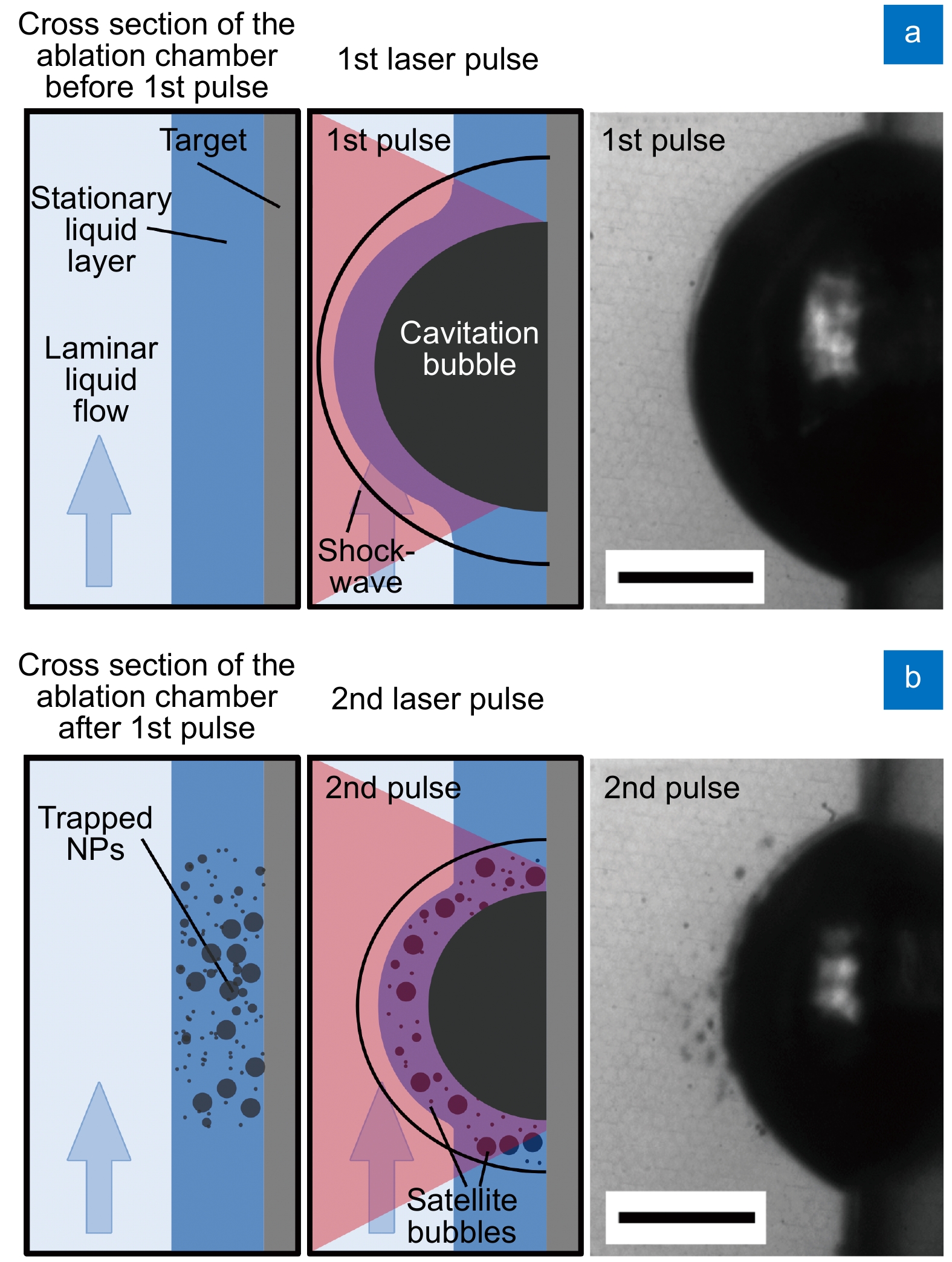

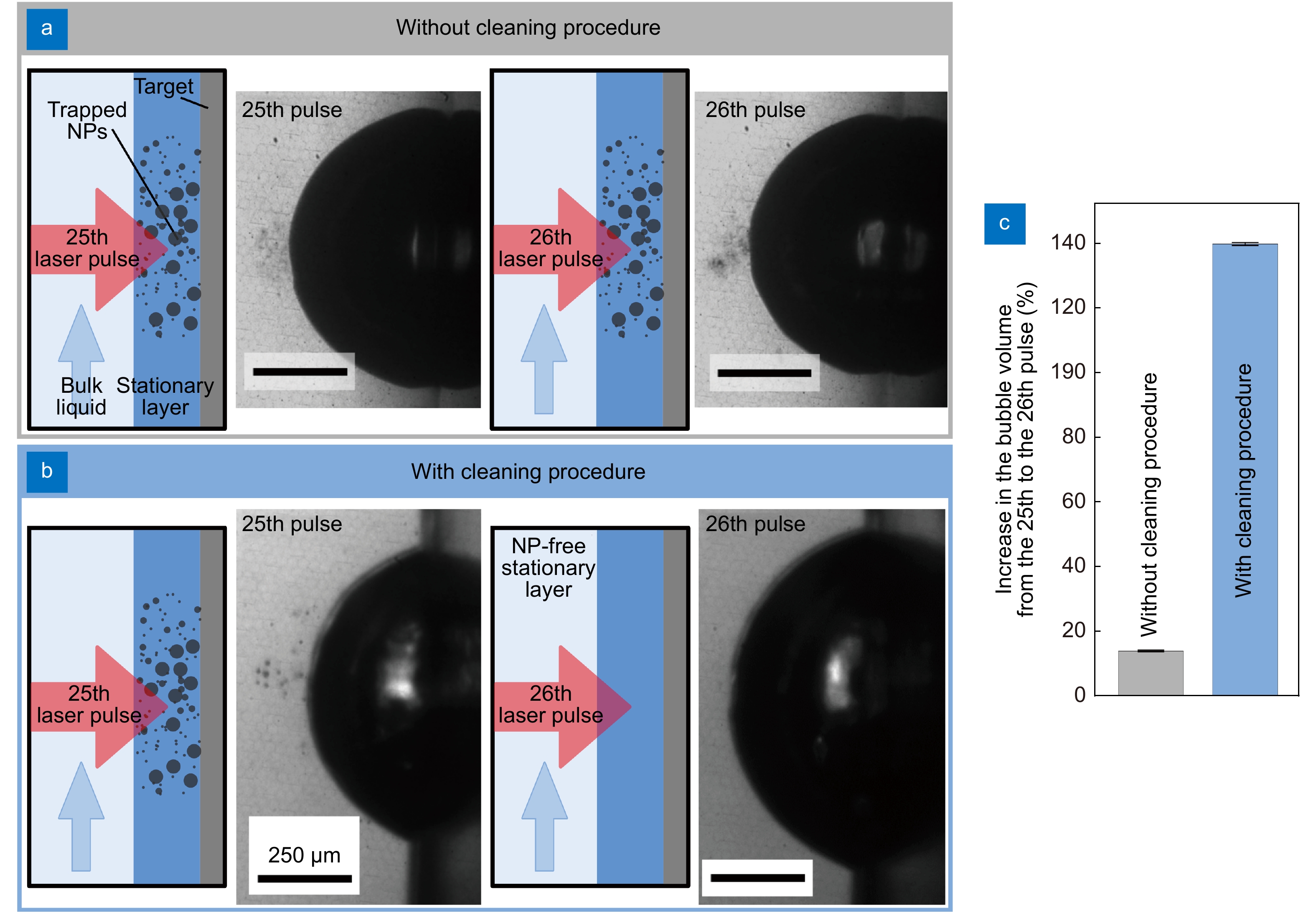

Understanding shielding cross-effects is a prerequisite for maximal power-specific nanosecond laser ablation in liquids (LAL). However, discrimination between cavitation bubble (CB), nanoparticle (NP), and shielding, e.g., by the plasma or a transient vapor layer, is challenging. Therefore, CB imaging by shadowgraphy is performed to better understand the plasma and laser beam-NP interaction during LAL. By comparing the fluence-dependent CB volume for ablations performed with 1 ns pulses with reports from the literature, we find larger energy-specific CB volumes for 7 ns-ablation. The increased CB for laser ablation with higher ns pulse durations could be a first explanation of the efficiency decrease reported for these laser systems having higher pulse durations. Consequently, 1 ns-LAL shows superior ablation efficiency. Moreover, a CB cascade occurs when the focal plane is shifted into the liquid. This effect is enhanced when NPs are present in the fluid. Even minute amounts of NPs trapped in a stationary layer decrease the laser energy significantly, even under liquid flow. However, this local concentration in the sticking film has so far not been considered. It presents an essential obstacle in high-yield LAL, shielding already the second laser pulse that arrives and presenting a source of satellite bubbles. Hence, measures to lower the NP concentration on the target must be investigated in the future.

Keywords

-

-

References

[1] Fojtik A, Henglein A. Laser ablation of films and suspended particles in a solvent-formation of cluster and colloid solutions. Ber Bunsen-Ges Phys Chem 97, 252–254 (1993).

[2] Zhang DS, Gökce B, Barcikowski S. Laser synthesis and processing of colloids: fundamentals and applications. Chem Rev 117, 3990–4103 (2017).

DOI: 10.1021/acs.chemrev.6b00468[3] Amans D, Cai WP, Barcikowski S. Status and demand of research to bring laser generation of nanoparticles in liquids to maturity. Appl Surf Sci 488, 445–454 (2019).

DOI: 10.1016/j.apsusc.2019.05.117[4] Dittrich S, Kohsakowski S, Wittek B, Hengst C, Gökce B et al. Increasing the size-selectivity in laser-based g/h liquid flow synthesis of Pt and PtPd nanoparticles for CO and NO oxidation in industrial automotive exhaust gas treatment benchmarking. Nanomaterials 10, 1582 (2020).

DOI: 10.3390/nano10081582[5] Barcikowski S, Baranowski T, Durmus Y, Wiedwald U, Gökce B. Solid solution magnetic FeNi nanostrand–polymer composites by connecting-coarsening assembly. J Mater Chem C 3, 10699–10704 (2015).

DOI: 10.1039/C5TC02160J[6] Neumeister A, Jakobi J, Rehbock C, Moysig J, Barcikowski S. Monophasic ligand-free alloy nanoparticle synthesis determinants during pulsed laser ablation of bulk alloy and consolidated microparticles in water. Phys Chem Chem Phys 16, 23671–23678 (2014).

DOI: 10.1039/C4CP03316G[7] Amendola V, Riello P, Meneghetti M. Magnetic nanoparticles of iron carbide, iron oxide, iron@iron oxide, and metal iron synthesized by laser ablation in organic solvents. J Phys Chem C 115, 5140–5146 (2011).

DOI: 10.1021/jp109371m[8] Amendola V, Fortunati I, Marega C, Abdelhady AL, Saidaminov MI et al. High-purity hybrid organolead halide perovskite nanoparticles obtained by pulsed-laser irradiation in liquid. ChemPhysChem 18, 1047–1054 (2017).

DOI: 10.1002/cphc.201600863[9] Streubel R, Bendt G, Gökce B. Pilot-scale synthesis of metal nanoparticles by high-speed pulsed laser ablation in liquids. Nanotechnology 27, 205602 (2016).

DOI: 10.1088/0957-4484/27/20/205602[10] Reichenberger S, Marzun G, Muhler M, Barcikowski S. Perspective of surfactant-free colloidal nanoparticles in heterogeneous catalysis. ChemCatChem 11, 4489–4518 (2019).

DOI: 10.1002/cctc.201900666[11] Rodio M, Coluccino L, Romeo E, Genovese A, Diaspro A et al. Facile fabrication of bioactive ultra-small protein-hydroxyapatite nanoconjugates via liquid-phase laser ablation and their enhanced osteogenic differentiation activity. J Mater Chem B 5, 279–288 (2017).

DOI: 10.1039/C6TB02023B[12] Ikehata T, Onodera Y, Nunokawa T, Hirano T, Ogura SI et al. Photodynamic therapy using upconversion nanoparticles prepared by laser ablation in liquid. Appl Surf Sci 348, 54–59 (2015).

DOI: 10.1016/j.apsusc.2014.12.097[13] Hupfeld T, Wegner A, Blanke M, Doñate‐Buendía C, Sharov V et al. Plasmonic Seasoning: giving color to desktop laser 3D printed polymers by highly dispersed nanoparticles. Adv Optical Mater 8, 2000473 (2020).

DOI: 10.1002/adom.202000473[14] Doñate-Buendía C, Frömel F, Wilms MB, Streubel R, Tenkamp J et al. Oxide dispersion-strengthened alloys generated by laser metal deposition of laser-generated nanoparticle-metal powder composites. Mater Des 154, 360–369 (2018).

DOI: 10.1016/j.matdes.2018.05.044[15] Hupfeld T, Laumer T, Stichel T, Schuffenhauer T, Heberle J et al. A new approach to coat PA12 powders with laser-generated nanoparticles for selective laser sintering. Procedia CIRP 74, 244–248 (2018).

DOI: 10.1016/j.procir.2018.08.103[16] Muniz-Miranda M, Gellini C, Giorgetti E. Surface-enhanced Raman scattering from copper nanoparticles obtained by laser ablation. J Phys Chem C 115, 5021–5027 (2011).

DOI: 10.1021/jp1086027[17] Amendola V, Litti L, Meneghetti M. LDI-MS assisted by chemical-free gold nanoparticles: enhanced sensitivity and reduced background in the low-mass region. Anal Chem 85, 11747–11754 (2013).

DOI: 10.1021/ac401662r[18] Jendrzej S, Gökce B, Epple M, Barcikowski S. How size determines the value of gold: economic aspects of wet chemical and laser-based metal colloid synthesis. ChemPhysChem 18, 1012–1019 (2017).

DOI: 10.1002/cphc.201601139[19] Neuenschwander B, Jaeggi B, Schmid M, Rouffiange V, Martin P E. Optimization of the volume ablation rate for metals at different laser pulse-durations from ps to fs. Proc SPIE 8243, 824307 (2012).

DOI: 10.1117/12.908583[20] Dittrich S, Streubel R, McDonnell C, Huber HP, Barcikowski S et al. Comparison of the productivity and ablation efficiency of different laser classes for laser ablation of gold in water and air. Appl Phys A 125, 432 (2019).

DOI: 10.1007/s00339-019-2704-8[21] Neuenschwander B, Jaeggi B, Schmid M, Hennig G. Surface structuring with ultra-short laser pulses: basics, limitations and needs for high throughput. Phys Proc 56, 1047–1058 (2014).

DOI: 10.1016/j.phpro.2014.08.017[22] Streubel R, Barcikowski S, Gökce B. Continuous multigram nanoparticle synthesis by high-power, high-repetition-rate ultrafast laser ablation in liquids. Opt Lett 41, 1486–1489 (2016).

DOI: 10.1364/OL.41.001486[23] Račiukaitis G, Brikas M, Gečys P, Voisiat B, Gedvilas M. Use of high repetition rate and high power lasers in microfabrication: how to keep the efficiency high?. J Laser Micro/Nanoeng 4, 186–191 (2009).

DOI: 10.2961/jlmn.2009.03.0008[24] Forster M, Égerházi L, Haselberger C, Huber C, Kautek W. Femtosecond laser interaction with pulsed-laser deposited carbon thin films of nanoscale thickness. Appl Phys A 102, 27–33 (2011).

DOI: 10.1007/s00339-010-6013-5[25] Belevtsev BI, Komnik YF, Beliayev EY. Electron relaxation in disordered gold films. Phys Rev B 58, 8079–8086 (1998).

DOI: 10.1103/PhysRevB.58.8079[26] Johnson PB, Christy RW. Optical constants of the noble metals. Phys Rev B 6, 4370–4379 (1972).

DOI: 10.1103/PhysRevB.6.4370[27] McPeak KM, Jayanti SV, Kress SJP, Meyer S, Iotti S et al. Plasmonic films can easily be better: rules and recipes. ACS Photonics 2, 326–333 (2015).

DOI: 10.1021/ph5004237[28] Babar S, Weaver JH. Optical constants of Cu, Ag, and Au revisited. Appl Opt 54, 477–481 (2015).

DOI: 10.1364/AO.54.000477[29] Olmon RL, Slovick B, Johnson TW, Shelton D, Oh SH et al. Optical dielectric function of gold. Phys Rev B 86, 235147 (2012).

DOI: 10.1103/PhysRevB.86.235147[30] Werner WSM, Glantschnig K, Ambrosch-Draxl C. Optical constants and inelastic electron-scattering data for 17 elemental metals. J Phys Chem Ref Data 38, 1013–1092 (2009).

DOI: 10.1063/1.3243762[31] Gamaly EG, Rode AV, Luther-Davies B, Tikhonchuk VT. Ablation of solids by femtosecond lasers: ablation mechanism and ablation thresholds for metals and dielectrics. Phys Plasmas 9, 949–957 (2002).

DOI: 10.1063/1.1447555[32] Stuart BC, Feit MD, Herman S, Rubenchik AM, Shore BW et al. Optical ablation by high-power short-pulse lasers. J Opt Soc Am B 13, 459–468 (1996).

DOI: 10.1364/JOSAB.13.000459[33] Tomko J, Naddeo JJ, Jimenez R, Tan Y, Steiner M et al. Size and polydispersity trends found in gold nanoparticles synthesized by laser ablation in liquids. Phys Chem Chem Phys 17, 16327–16333 (2015).

DOI: 10.1039/C5CP01965F[34] Venkatakrishnan K, Stanley P, Sivakumar NR, Tan B, Lim LEN. Effect of scanning resolution and fluence fluctuation on femtosecond laser ablation of thin films. Appl Phys A 77, 655–658 (2003).

DOI: 10.1007/s00339-002-1668-1[35] Krüger J, Dufft D, Koter R, Hertwig A. Femtosecond laser-induced damage of gold films. Appl Surf Sci 253, 7815–7819 (2007).

DOI: 10.1016/j.apsusc.2007.02.164[36] Boedefeld R, Schreiber J, Gessner H, Welsch E, Theobald W et al. Optical damage of sputtered gold films irradiated with femtosecond laser pulses. Proc SPIE 4347, 45–52 (2001).

DOI: 10.1117/12.425075[37] Starinskiy SV, Shukhov YG, Bulgakov AV. Laser-induced damage thresholds of gold, silver and their alloys in air and water. Appl Surf Sci 396, 1765–1774 (2017).

DOI: 10.1016/j.apsusc.2016.11.221[38] Kalus MR, Lanyumba R, Lorenzo-Parodi N, Jochmann MA, Kerpen K et al. Determining the role of redox-active materials during laser-induced water decomposition. Phys Chem Chem Phys 21, 18636–18651 (2019).

DOI: 10.1039/C9CP02663K[39] Kalus MR, Reimer V, Barcikowski S, Gökce B. Discrimination of effects leading to gas formation during pulsed laser ablation in liquids. Appl Surf Sci 465, 1096–1102 (2019).

DOI: 10.1016/j.apsusc.2018.09.224[40] Sakka T, Masai S, Fukami K, Ogata YH. Spectral profile of atomic emission lines and effects of pulse duration on laser ablation in liquid. Spectrochim Acta Part B At Spectrosc 64, 981–985 (2009).

DOI: 10.1016/j.sab.2009.07.018[41] Kanitz A, Kalus MR, Gurevich EL, Ostendorf A, Barcikowski S et al. Review on experimental and theoretical investigations of the early stage, femtoseconds to microseconds processes during laser ablation in liquid-phase for the synthesis of colloidal nanoparticles. Plasma Sources Sci Technol 28, 103001 (2019).

DOI: 10.1088/1361-6595/ab3dbe[42] Shih CY, Wu CP, Shugaev MV, Zhigilei LV. Atomistic modeling of nanoparticle generation in short pulse laser ablation of thin metal films in water. J Colloid Interface Sci 489, 3–17 (2017).

DOI: 10.1016/j.jcis.2016.10.029[43] Shih CY, Shugaev MV, Wu CP, Zhigilei LV. Generation of subsurface voids, incubation effect, and formation of nanoparticles in short pulse laser interactions with bulk metal targets in liquid: molecular dynamics study. J Phys Chem C 121, 16549–16567 (2017).

DOI: 10.1021/acs.jpcc.7b02301[44] Shih CY, Shugaev MV, Wu CP, Zhigilei LV. The effect of pulse duration on nanoparticle generation in pulsed laser ablation in liquids: insights from large-scale atomistic simulations. Phys Chem Chem Phys 22, 7077–7099 (2020).

DOI: 10.1039/D0CP00608D[45] Kanitz A, Förster DJ, Hoppius JS, Weber R, Ostendorf A et al. Pump-probe microscopy of femtosecond laser ablation in air and liquids. Appl Surf Sci 475, 204–210 (2019).

DOI: 10.1016/j.apsusc.2018.12.184[46] Kanitz A, Hoppius JS, Fiebrandt M, Awakowicz P, Esen C et al. Impact of liquid environment on femtosecond laser ablation. Appl Phys A 123, 674 (2017).

DOI: 10.1007/s00339-017-1280-z[47] Tamura A, Matsumoto A, Fukami K, Nishi N, Sakka T. Simultaneous observation of nascent plasma and bubble induced by laser ablation in water with various pulse durations. J Appl Phys 117, 173304 (2015).

DOI: 10.1063/1.4919729[48] DellʼAglio M, Gaudiuso R, de Pascale O, de Giacomo A. Mechanisms and processes of pulsed laser ablation in liquids during nanoparticle production. Appl Surf Sci 348, 4–9 (2015).

DOI: 10.1016/j.apsusc.2015.01.082[49] Kumar B, Thareja RK. Growth of titanium nanoparticles in confined plasma. Phys Plasmas 19, 033516 (2012).

DOI: 10.1063/1.3697978[50] Noack J, Vogel A. Laser-induced plasma formation in water at nanosecond to femtosecond time scales: calculation of thresholds, absorption coefficients, and energy density. IEEE J Quantum Electron 35, 1156–1167 (1999).

DOI: 10.1109/3.777215[51] Vogel A, Venugopalan V. Mechanisms of pulsed laser ablation of biological tissues. Chem Rev 103, 577–644 (2003).

DOI: 10.1021/cr010379n[52] Vogel A, Busch S, Parlitz U. Shock wave emission and cavitation bubble generation by picosecond and nanosecond optical breakdown in water. J Acoust Soc Am 100, 148–165 (1996).

DOI: 10.1121/1.415878[53] Boulais É, Lachaine R, Meunier M. Plasma mediated off-resonance plasmonic enhanced ultrafast laser-induced nanocavitation. Nano Lett 12, 4763–4769 (2012).

DOI: 10.1021/nl302200w[54] Kotaidis V, Plech A. Cavitation dynamics on the nanoscale. Appl Phys Lett 87, 213102 (2005).

DOI: 10.1063/1.2132086[55] Lombard J, Biben T, Merabia S. Ballistic heat transport in laser generated nano-bubbles. Nanoscale 8, 14870–14876 (2016).

DOI: 10.1039/C6NR02144A[56] Neumann J, Brinkmann R. Self-limited growth of laser-induced vapor bubbles around single microabsorbers. Appl Phys Lett 93, 033901 (2008).

DOI: 10.1063/1.2957030[57] Lapotko D. Optical excitation and detection of vapor bubbles around plasmonic nanoparticles. Opt Express 17, 2538–2556 (2009).

DOI: 10.1364/OE.17.002538[58] Siems A, Weber SAL, Boneberg J, Plech A. Thermodynamics of nanosecond nanobubble formation at laser-excited metal nanoparticles. New J Phys 13, 043018 (2011).

DOI: 10.1088/1367-2630/13/4/043018[59] Ko B, Lu W, Sokolov AV, Lee HWH, Scully MO et al. Multi-pulse laser-induced bubble formation and nanoparticle aggregation using MoS2 nanoparticles. Sci Rep 10, 15753 (2020).

DOI: 10.1038/s41598-020-72689-x[60] Kotaidis V, Dahmen C, von Plessen G, Springer F, Plech A. Excitation of nanoscale vapor bubbles at the surface of gold nanoparticles in water. J Chem Phys 124, 184702 (2006).

DOI: 10.1063/1.2187476[61] Koechner W. Solid-State Laser Engineering Vol. 1 (Springer Series in Optical Sciences, New York, 2006).

[62] Letzel A, Santoro M, Frohleiks J, Ziefuß AR, Reich S et al. How the re-irradiation of a single ablation spot affects cavitation bubble dynamics and nanoparticles properties in laser ablation in liquids. Appl Surf Sci 473, 828–837 (2019).

DOI: 10.1016/j.apsusc.2018.12.025[63] Reich S, Letzel A, Gökce B, Menzel A, Barcikowski S et al. Incubation effect of pre-irradiation on bubble formation and ablation in laser ablation in liquids. ChemPhysChem 20, 1036–1043 (2019).

DOI: 10.1002/cphc.201900075[64] Liu JM. Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt Lett 7, 196–198 (1982).

DOI: 10.1364/OL.7.000196[65] Wang QX, Manmi K. Three dimensional microbubble dynamics near a wall subject to high intensity ultrasound. Phys Fluids 26, 032104 (2014).

DOI: 10.1063/1.4866772[66] Taccogna F, Dell’Aglio M, Rutigliano M, Valenza G, de Giacomo A. On the growth mechanism of nanoparticles in plasma during pulsed laser ablation in liquids. Plasma Sources Sci Technol 26, 045002 (2017).

DOI: 10.1088/1361-6595/aa595b[67] Reich S, Schönfeld P, Letzel A, Kohsakowski S, Olbinado M et al. Fluence threshold behaviour on ablation and bubble formation in pulsed laser ablation in liquids. ChemPhysChem 18, 1084–1090 (2017).

DOI: 10.1002/cphc.201601198[68] Bulgakova NM, Bulgakov AV, Bourakov IM, Bulgakova NA. Pulsed laser ablation of solids and critical phenomena. Appl Surf Sci 197–198, 96–99 (2002).

DOI: 10.1016/S0169-4332(02)00310-0[69] Kohsakowski S, Seiser F, Wiederrecht JP, Reichenberger S, Vinnay T et al. Effective size separation of laser-generated, surfactant-free nanoparticles by continuous centrifugation. Nanotechnology 31, 095603 (2020).

DOI: 10.1088/1361-6528/ab55bd[70] Riabinina D, Chaker M, Margot J. Dependence of gold nanoparticle production on pulse duration by laser ablation in liquid media. Nanotechnology 23, 135603 (2012).

DOI: 10.1088/0957-4484/23/13/135603[71] Stasic J, Joksic G, Zivkovic L, Mihailescu IN, Ghica C et al. Focusing geometry-induced size tailoring of silver nanoparticles obtained by laser ablation in water. Laser Phys 24, 106005 (2014).

DOI: 10.1088/1054-660X/24/10/106005[72] Elsayed KA, Imam H, Ahmed MA, Ramadan R. Effect of focusing conditions and laser parameters on the fabrication of gold nanoparticles via laser ablation in liquid. Opt Laser Technol 45, 495–502 (2013).

DOI: 10.1016/j.optlastec.2012.06.004[73] Waag F, Gökce B, Barcikowski S. Ablation target cooling by maximizing the nanoparticle productivity in laser synthesis of colloids. Appl Surf Sci 466, 647–656 (2019).

DOI: 10.1016/j.apsusc.2018.10.030[74] Maciulevičius M, Vinčiūnas A, Brikas M, Butsen A, Tarasenka N et al. Pulsed-laser generation of gold nanoparticles with on-line surface Plasmon resonance detection. Appl Phys A 111, 289–295 (2013).

DOI: 10.1007/s00339-012-7535-9[75] Reich S, Schönfeld P, Wagener P, Letzel A, Ibrahimkutty S et al. Pulsed laser ablation in liquids: impact of the bubble dynamics on particle formation. J Colloid Interface Sci 489, 106–113 (2017).

DOI: 10.1016/j.jcis.2016.08.030[76] Tanabe R, Nguyen TTP, Sugiura T, Ito Y. Bubble dynamics in metal nanoparticle formation by laser ablation in liquid studied through high-speed laser stroboscopic videography. Appl Surf Sci 351, 327–331 (2015).

DOI: 10.1016/j.apsusc.2015.05.030[77] Metwally K, Mensah S, Baffou G. Fluence threshold for photothermal bubble generation using plasmonic nanoparticles. J Phys Chem C 119, 28586–28596 (2015).

DOI: 10.1021/acs.jpcc.5b09903[78] Liu HW, Chen F, Wang XH, Yang Q, Bian H et al. Influence of liquid environments on femtosecond laser ablation of silicon. Thin Solid Films 518, 5188–5194 (2010).

DOI: 10.1016/j.tsf.2010.04.043[79] Delfour L, Itina TE. Mechanisms of ultrashort laser-induced fragmentation of metal nanoparticles in liquids: numerical insights. J Phys Chem C 119, 13893–13900 (2015).

DOI: 10.1021/acs.jpcc.5b02084[80] Dakka A, Lafait J, Sella C, Berthier S, Abd-Lefdil M et al. Optical properties of Ag–TiO2 nanocermet films prepared by cosputtering and multilayer deposition techniques. Appl Opt 39, 2745–2753 (2000).

DOI: 10.1364/AO.39.002745[81] Lau M, Barcikowski S. Quantification of mass-specific laser energy input converted into particle properties during picosecond pulsed laser fragmentation of zinc oxide and boron carbide in liquids. Appl Surf Sci 348, 22–29 (2015).

DOI: 10.1016/j.apsusc.2014.07.053[82] Werner D, Furube A, Okamoto T, Hashimoto S. Femtosecond laser-induced size reduction of aqueous gold nanoparticles: in situ and pump−probe spectroscopy investigations revealing coulomb explosion. J Phys Chem C 115, 8503–8512 (2011).

DOI: 10.1021/jp112262u[83] Ziefuß AR, Reichenberger S, Rehbock C, Chakraborty I, Gharib M et al. Laser fragmentation of colloidal gold nanoparticles with high-intensity nanosecond pulses is driven by a single-step fragmentation mechanism with a defined Educt particle-size threshold. J Phys Chem C 122, 22125–22136 (2018).

DOI: 10.1021/acs.jpcc.8b04374[84] Sylvestre JP, Kabashin AV, Sacher E, Meunier M. Femtosecond laser ablation of gold in water: influence of the laser-produced plasma on the nanoparticle size distribution. Appl Phys A 80, 753–758 (2005).

DOI: 10.1007/s00339-004-3081-4[85] Brujan EA, Nahen K, Schmidt P, Vogel A. Dynamics of laser-induced cavitation bubbles near an elastic boundary. J Fluid Mech 433, 251–281 (2001).

DOI: 10.1017/S0022112000003347[86] Harris DM, Pucci G, Prost V, Quintela Casal J, Bush JWM. Video: The merger of a bubble and a soap film. In 68th Annual Meeting of the APS Division of Fluid Dynamics - Gallery of Fluid Motion (American Physical Society, 2015).

[87] Lewis WK, Whitman WG. Principles of gas absorption. Ind Eng Chem 16, 1215–1220 (1924).

DOI: 10.1021/ie50180a002[88] Shih CY, Streubel R, Heberle J, Letzel A, Shugaev MV et al. Two mechanisms of nanoparticle generation in picosecond laser ablation in liquids: the origin of the bimodal size distribution. Nanoscale 10, 6900–6910 (2018).

DOI: 10.1039/C7NR08614H[89] Long JY, Eliceiri M, Vangelatos Z, Rho Y, Wang LT et al. Early dynamics of cavitation bubbles generated during ns laser ablation of submerged targets. Opt Express 28, 14300–14309 (2020).

DOI: 10.1364/OE.391584[90] Jakubith M. Grundoperationen Und Chemische Reaktionstechnik: Eine Einführung in Die Technische Chemie (Wiley-VCH, Weinheim, 1998).

View full references list -

Author Information

-

Sarah Dittrich On this SiteOn Google Scholar

-

Corresponding author: Stephan Barcikowski, stephan.barcikowski@uni-due.de On this SiteOn Google Scholar

S Barcikowski, E-mail: stephan.barcikowski@uni-due.de -

Bilal Gökce On this SiteOn Google Scholar

-

-

Supplementary Information

-

Copyright

Open Access. © The Author(s). This article is licensed under a Creative Commons Attribution 4.0 International License. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/. -

About this Article

Cite this Article

Sarah Dittrich, Stephan Barcikowski, Bilal Gökce. Plasma and nanoparticle shielding during pulsed laser ablation in liquids cause ablation efficiency decrease. Opto-Electronic Advances 4, 200072 (2021). DOI: 10.29026/oea.2021.200072Sarah Dittrich, Stephan Barcikowski, Bilal Gökce. Plasma and nanoparticle shielding during pulsed laser ablation in liquids cause ablation efficiency decrease. Opto-Electronic Advances 4, 200072 (2021). DOI: 10.29026/oea.2021.200072Download CitationArticle History

- Received Date October 19, 2020

- Accepted Date December 02, 2020

- Available Online January 26, 2021

- Published Date January 26, 2021

-

Related Articles

Competing interests

The authors declare no competing financial interests.

Author contributions

S. D. performed the measurements and proposed the firstdraft of the manuscript. S. B. and B. G. proposed the origin-al idea and supervised the project. All authors revised themanuscript.

| [1] |

Fojtik A, Henglein A. Laser ablation of films and suspended particles in a solvent-formation of cluster and colloid solutions. Ber Bunsen-Ges Phys Chem 97, 252–254 (1993). |

| [2] |

Zhang DS, Gökce B, Barcikowski S. Laser synthesis and processing of colloids: fundamentals and applications. Chem Rev 117, 3990–4103 (2017). DOI: 10.1021/acs.chemrev.6b00468 |

| [3] |

Amans D, Cai WP, Barcikowski S. Status and demand of research to bring laser generation of nanoparticles in liquids to maturity. Appl Surf Sci 488, 445–454 (2019). DOI: 10.1016/j.apsusc.2019.05.117 |

| [4] |

Dittrich S, Kohsakowski S, Wittek B, Hengst C, Gökce B et al. Increasing the size-selectivity in laser-based g/h liquid flow synthesis of Pt and PtPd nanoparticles for CO and NO oxidation in industrial automotive exhaust gas treatment benchmarking. Nanomaterials 10, 1582 (2020). DOI: 10.3390/nano10081582 |

| [5] |

Barcikowski S, Baranowski T, Durmus Y, Wiedwald U, Gökce B. Solid solution magnetic FeNi nanostrand–polymer composites by connecting-coarsening assembly. J Mater Chem C 3, 10699–10704 (2015). DOI: 10.1039/C5TC02160J |

| [6] |

Neumeister A, Jakobi J, Rehbock C, Moysig J, Barcikowski S. Monophasic ligand-free alloy nanoparticle synthesis determinants during pulsed laser ablation of bulk alloy and consolidated microparticles in water. Phys Chem Chem Phys 16, 23671–23678 (2014). DOI: 10.1039/C4CP03316G |

| [7] |

Amendola V, Riello P, Meneghetti M. Magnetic nanoparticles of iron carbide, iron oxide, iron@iron oxide, and metal iron synthesized by laser ablation in organic solvents. J Phys Chem C 115, 5140–5146 (2011). DOI: 10.1021/jp109371m |

| [8] |

Amendola V, Fortunati I, Marega C, Abdelhady AL, Saidaminov MI et al. High-purity hybrid organolead halide perovskite nanoparticles obtained by pulsed-laser irradiation in liquid. ChemPhysChem 18, 1047–1054 (2017). DOI: 10.1002/cphc.201600863 |

| [9] |

Streubel R, Bendt G, Gökce B. Pilot-scale synthesis of metal nanoparticles by high-speed pulsed laser ablation in liquids. Nanotechnology 27, 205602 (2016). DOI: 10.1088/0957-4484/27/20/205602 |

| [10] |

Reichenberger S, Marzun G, Muhler M, Barcikowski S. Perspective of surfactant-free colloidal nanoparticles in heterogeneous catalysis. ChemCatChem 11, 4489–4518 (2019). DOI: 10.1002/cctc.201900666 |

| [11] |

Rodio M, Coluccino L, Romeo E, Genovese A, Diaspro A et al. Facile fabrication of bioactive ultra-small protein-hydroxyapatite nanoconjugates via liquid-phase laser ablation and their enhanced osteogenic differentiation activity. J Mater Chem B 5, 279–288 (2017). DOI: 10.1039/C6TB02023B |

| [12] |

Ikehata T, Onodera Y, Nunokawa T, Hirano T, Ogura SI et al. Photodynamic therapy using upconversion nanoparticles prepared by laser ablation in liquid. Appl Surf Sci 348, 54–59 (2015). DOI: 10.1016/j.apsusc.2014.12.097 |

| [13] |

Hupfeld T, Wegner A, Blanke M, Doñate‐Buendía C, Sharov V et al. Plasmonic Seasoning: giving color to desktop laser 3D printed polymers by highly dispersed nanoparticles. Adv Optical Mater 8, 2000473 (2020). DOI: 10.1002/adom.202000473 |

| [14] |

Doñate-Buendía C, Frömel F, Wilms MB, Streubel R, Tenkamp J et al. Oxide dispersion-strengthened alloys generated by laser metal deposition of laser-generated nanoparticle-metal powder composites. Mater Des 154, 360–369 (2018). DOI: 10.1016/j.matdes.2018.05.044 |

| [15] |

Hupfeld T, Laumer T, Stichel T, Schuffenhauer T, Heberle J et al. A new approach to coat PA12 powders with laser-generated nanoparticles for selective laser sintering. Procedia CIRP 74, 244–248 (2018). DOI: 10.1016/j.procir.2018.08.103 |

| [16] |

Muniz-Miranda M, Gellini C, Giorgetti E. Surface-enhanced Raman scattering from copper nanoparticles obtained by laser ablation. J Phys Chem C 115, 5021–5027 (2011). DOI: 10.1021/jp1086027 |

| [17] |

Amendola V, Litti L, Meneghetti M. LDI-MS assisted by chemical-free gold nanoparticles: enhanced sensitivity and reduced background in the low-mass region. Anal Chem 85, 11747–11754 (2013). DOI: 10.1021/ac401662r |

| [18] |

Jendrzej S, Gökce B, Epple M, Barcikowski S. How size determines the value of gold: economic aspects of wet chemical and laser-based metal colloid synthesis. ChemPhysChem 18, 1012–1019 (2017). DOI: 10.1002/cphc.201601139 |

| [19] |

Neuenschwander B, Jaeggi B, Schmid M, Rouffiange V, Martin P E. Optimization of the volume ablation rate for metals at different laser pulse-durations from ps to fs. Proc SPIE 8243, 824307 (2012). DOI: 10.1117/12.908583 |

| [20] |

Dittrich S, Streubel R, McDonnell C, Huber HP, Barcikowski S et al. Comparison of the productivity and ablation efficiency of different laser classes for laser ablation of gold in water and air. Appl Phys A 125, 432 (2019). DOI: 10.1007/s00339-019-2704-8 |

| [21] |

Neuenschwander B, Jaeggi B, Schmid M, Hennig G. Surface structuring with ultra-short laser pulses: basics, limitations and needs for high throughput. Phys Proc 56, 1047–1058 (2014). DOI: 10.1016/j.phpro.2014.08.017 |

| [22] |

Streubel R, Barcikowski S, Gökce B. Continuous multigram nanoparticle synthesis by high-power, high-repetition-rate ultrafast laser ablation in liquids. Opt Lett 41, 1486–1489 (2016). DOI: 10.1364/OL.41.001486 |

| [23] |

Račiukaitis G, Brikas M, Gečys P, Voisiat B, Gedvilas M. Use of high repetition rate and high power lasers in microfabrication: how to keep the efficiency high?. J Laser Micro/Nanoeng 4, 186–191 (2009). DOI: 10.2961/jlmn.2009.03.0008 |

| [24] |

Forster M, Égerházi L, Haselberger C, Huber C, Kautek W. Femtosecond laser interaction with pulsed-laser deposited carbon thin films of nanoscale thickness. Appl Phys A 102, 27–33 (2011). DOI: 10.1007/s00339-010-6013-5 |

| [25] |

Belevtsev BI, Komnik YF, Beliayev EY. Electron relaxation in disordered gold films. Phys Rev B 58, 8079–8086 (1998). DOI: 10.1103/PhysRevB.58.8079 |

| [26] |

Johnson PB, Christy RW. Optical constants of the noble metals. Phys Rev B 6, 4370–4379 (1972). DOI: 10.1103/PhysRevB.6.4370 |

| [27] |

McPeak KM, Jayanti SV, Kress SJP, Meyer S, Iotti S et al. Plasmonic films can easily be better: rules and recipes. ACS Photonics 2, 326–333 (2015). DOI: 10.1021/ph5004237 |

| [28] |

Babar S, Weaver JH. Optical constants of Cu, Ag, and Au revisited. Appl Opt 54, 477–481 (2015). DOI: 10.1364/AO.54.000477 |

| [29] |

Olmon RL, Slovick B, Johnson TW, Shelton D, Oh SH et al. Optical dielectric function of gold. Phys Rev B 86, 235147 (2012). DOI: 10.1103/PhysRevB.86.235147 |

| [30] |

Werner WSM, Glantschnig K, Ambrosch-Draxl C. Optical constants and inelastic electron-scattering data for 17 elemental metals. J Phys Chem Ref Data 38, 1013–1092 (2009). DOI: 10.1063/1.3243762 |

| [31] |

Gamaly EG, Rode AV, Luther-Davies B, Tikhonchuk VT. Ablation of solids by femtosecond lasers: ablation mechanism and ablation thresholds for metals and dielectrics. Phys Plasmas 9, 949–957 (2002). DOI: 10.1063/1.1447555 |

| [32] |

Stuart BC, Feit MD, Herman S, Rubenchik AM, Shore BW et al. Optical ablation by high-power short-pulse lasers. J Opt Soc Am B 13, 459–468 (1996). DOI: 10.1364/JOSAB.13.000459 |

| [33] |

Tomko J, Naddeo JJ, Jimenez R, Tan Y, Steiner M et al. Size and polydispersity trends found in gold nanoparticles synthesized by laser ablation in liquids. Phys Chem Chem Phys 17, 16327–16333 (2015). DOI: 10.1039/C5CP01965F |

| [34] |

Venkatakrishnan K, Stanley P, Sivakumar NR, Tan B, Lim LEN. Effect of scanning resolution and fluence fluctuation on femtosecond laser ablation of thin films. Appl Phys A 77, 655–658 (2003). DOI: 10.1007/s00339-002-1668-1 |

| [35] |

Krüger J, Dufft D, Koter R, Hertwig A. Femtosecond laser-induced damage of gold films. Appl Surf Sci 253, 7815–7819 (2007). DOI: 10.1016/j.apsusc.2007.02.164 |

| [36] |

Boedefeld R, Schreiber J, Gessner H, Welsch E, Theobald W et al. Optical damage of sputtered gold films irradiated with femtosecond laser pulses. Proc SPIE 4347, 45–52 (2001). DOI: 10.1117/12.425075 |

| [37] |

Starinskiy SV, Shukhov YG, Bulgakov AV. Laser-induced damage thresholds of gold, silver and their alloys in air and water. Appl Surf Sci 396, 1765–1774 (2017). DOI: 10.1016/j.apsusc.2016.11.221 |

| [38] |

Kalus MR, Lanyumba R, Lorenzo-Parodi N, Jochmann MA, Kerpen K et al. Determining the role of redox-active materials during laser-induced water decomposition. Phys Chem Chem Phys 21, 18636–18651 (2019). DOI: 10.1039/C9CP02663K |

| [39] |

Kalus MR, Reimer V, Barcikowski S, Gökce B. Discrimination of effects leading to gas formation during pulsed laser ablation in liquids. Appl Surf Sci 465, 1096–1102 (2019). DOI: 10.1016/j.apsusc.2018.09.224 |

| [40] |

Sakka T, Masai S, Fukami K, Ogata YH. Spectral profile of atomic emission lines and effects of pulse duration on laser ablation in liquid. Spectrochim Acta Part B At Spectrosc 64, 981–985 (2009). DOI: 10.1016/j.sab.2009.07.018 |

| [41] |

Kanitz A, Kalus MR, Gurevich EL, Ostendorf A, Barcikowski S et al. Review on experimental and theoretical investigations of the early stage, femtoseconds to microseconds processes during laser ablation in liquid-phase for the synthesis of colloidal nanoparticles. Plasma Sources Sci Technol 28, 103001 (2019). DOI: 10.1088/1361-6595/ab3dbe |

| [42] |

Shih CY, Wu CP, Shugaev MV, Zhigilei LV. Atomistic modeling of nanoparticle generation in short pulse laser ablation of thin metal films in water. J Colloid Interface Sci 489, 3–17 (2017). DOI: 10.1016/j.jcis.2016.10.029 |

| [43] |

Shih CY, Shugaev MV, Wu CP, Zhigilei LV. Generation of subsurface voids, incubation effect, and formation of nanoparticles in short pulse laser interactions with bulk metal targets in liquid: molecular dynamics study. J Phys Chem C 121, 16549–16567 (2017). DOI: 10.1021/acs.jpcc.7b02301 |

| [44] |

Shih CY, Shugaev MV, Wu CP, Zhigilei LV. The effect of pulse duration on nanoparticle generation in pulsed laser ablation in liquids: insights from large-scale atomistic simulations. Phys Chem Chem Phys 22, 7077–7099 (2020). DOI: 10.1039/D0CP00608D |

| [45] |

Kanitz A, Förster DJ, Hoppius JS, Weber R, Ostendorf A et al. Pump-probe microscopy of femtosecond laser ablation in air and liquids. Appl Surf Sci 475, 204–210 (2019). DOI: 10.1016/j.apsusc.2018.12.184 |

| [46] |

Kanitz A, Hoppius JS, Fiebrandt M, Awakowicz P, Esen C et al. Impact of liquid environment on femtosecond laser ablation. Appl Phys A 123, 674 (2017). DOI: 10.1007/s00339-017-1280-z |

| [47] |

Tamura A, Matsumoto A, Fukami K, Nishi N, Sakka T. Simultaneous observation of nascent plasma and bubble induced by laser ablation in water with various pulse durations. J Appl Phys 117, 173304 (2015). DOI: 10.1063/1.4919729 |

| [48] |

DellʼAglio M, Gaudiuso R, de Pascale O, de Giacomo A. Mechanisms and processes of pulsed laser ablation in liquids during nanoparticle production. Appl Surf Sci 348, 4–9 (2015). DOI: 10.1016/j.apsusc.2015.01.082 |

| [49] |

Kumar B, Thareja RK. Growth of titanium nanoparticles in confined plasma. Phys Plasmas 19, 033516 (2012). DOI: 10.1063/1.3697978 |

| [50] |

Noack J, Vogel A. Laser-induced plasma formation in water at nanosecond to femtosecond time scales: calculation of thresholds, absorption coefficients, and energy density. IEEE J Quantum Electron 35, 1156–1167 (1999). DOI: 10.1109/3.777215 |

| [51] |

Vogel A, Venugopalan V. Mechanisms of pulsed laser ablation of biological tissues. Chem Rev 103, 577–644 (2003). DOI: 10.1021/cr010379n |

| [52] |

Vogel A, Busch S, Parlitz U. Shock wave emission and cavitation bubble generation by picosecond and nanosecond optical breakdown in water. J Acoust Soc Am 100, 148–165 (1996). DOI: 10.1121/1.415878 |

| [53] |

Boulais É, Lachaine R, Meunier M. Plasma mediated off-resonance plasmonic enhanced ultrafast laser-induced nanocavitation. Nano Lett 12, 4763–4769 (2012). DOI: 10.1021/nl302200w |

| [54] |

Kotaidis V, Plech A. Cavitation dynamics on the nanoscale. Appl Phys Lett 87, 213102 (2005). DOI: 10.1063/1.2132086 |

| [55] |

Lombard J, Biben T, Merabia S. Ballistic heat transport in laser generated nano-bubbles. Nanoscale 8, 14870–14876 (2016). DOI: 10.1039/C6NR02144A |

| [56] |

Neumann J, Brinkmann R. Self-limited growth of laser-induced vapor bubbles around single microabsorbers. Appl Phys Lett 93, 033901 (2008). DOI: 10.1063/1.2957030 |

| [57] |

Lapotko D. Optical excitation and detection of vapor bubbles around plasmonic nanoparticles. Opt Express 17, 2538–2556 (2009). DOI: 10.1364/OE.17.002538 |

| [58] |

Siems A, Weber SAL, Boneberg J, Plech A. Thermodynamics of nanosecond nanobubble formation at laser-excited metal nanoparticles. New J Phys 13, 043018 (2011). DOI: 10.1088/1367-2630/13/4/043018 |

| [59] |

Ko B, Lu W, Sokolov AV, Lee HWH, Scully MO et al. Multi-pulse laser-induced bubble formation and nanoparticle aggregation using MoS2 nanoparticles. Sci Rep 10, 15753 (2020). DOI: 10.1038/s41598-020-72689-x |

| [60] |

Kotaidis V, Dahmen C, von Plessen G, Springer F, Plech A. Excitation of nanoscale vapor bubbles at the surface of gold nanoparticles in water. J Chem Phys 124, 184702 (2006). DOI: 10.1063/1.2187476 |

| [61] |

Koechner W. Solid-State Laser Engineering Vol. 1 (Springer Series in Optical Sciences, New York, 2006). |

| [62] |

Letzel A, Santoro M, Frohleiks J, Ziefuß AR, Reich S et al. How the re-irradiation of a single ablation spot affects cavitation bubble dynamics and nanoparticles properties in laser ablation in liquids. Appl Surf Sci 473, 828–837 (2019). DOI: 10.1016/j.apsusc.2018.12.025 |

| [63] |

Reich S, Letzel A, Gökce B, Menzel A, Barcikowski S et al. Incubation effect of pre-irradiation on bubble formation and ablation in laser ablation in liquids. ChemPhysChem 20, 1036–1043 (2019). DOI: 10.1002/cphc.201900075 |

| [64] |

Liu JM. Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt Lett 7, 196–198 (1982). DOI: 10.1364/OL.7.000196 |

| [65] |

Wang QX, Manmi K. Three dimensional microbubble dynamics near a wall subject to high intensity ultrasound. Phys Fluids 26, 032104 (2014). DOI: 10.1063/1.4866772 |

| [66] |

Taccogna F, Dell’Aglio M, Rutigliano M, Valenza G, de Giacomo A. On the growth mechanism of nanoparticles in plasma during pulsed laser ablation in liquids. Plasma Sources Sci Technol 26, 045002 (2017). DOI: 10.1088/1361-6595/aa595b |

| [67] |

Reich S, Schönfeld P, Letzel A, Kohsakowski S, Olbinado M et al. Fluence threshold behaviour on ablation and bubble formation in pulsed laser ablation in liquids. ChemPhysChem 18, 1084–1090 (2017). DOI: 10.1002/cphc.201601198 |

| [68] |

Bulgakova NM, Bulgakov AV, Bourakov IM, Bulgakova NA. Pulsed laser ablation of solids and critical phenomena. Appl Surf Sci 197–198, 96–99 (2002). DOI: 10.1016/S0169-4332(02)00310-0 |

| [69] |

Kohsakowski S, Seiser F, Wiederrecht JP, Reichenberger S, Vinnay T et al. Effective size separation of laser-generated, surfactant-free nanoparticles by continuous centrifugation. Nanotechnology 31, 095603 (2020). DOI: 10.1088/1361-6528/ab55bd |

| [70] |

Riabinina D, Chaker M, Margot J. Dependence of gold nanoparticle production on pulse duration by laser ablation in liquid media. Nanotechnology 23, 135603 (2012). DOI: 10.1088/0957-4484/23/13/135603 |

| [71] |

Stasic J, Joksic G, Zivkovic L, Mihailescu IN, Ghica C et al. Focusing geometry-induced size tailoring of silver nanoparticles obtained by laser ablation in water. Laser Phys 24, 106005 (2014). DOI: 10.1088/1054-660X/24/10/106005 |

| [72] |

Elsayed KA, Imam H, Ahmed MA, Ramadan R. Effect of focusing conditions and laser parameters on the fabrication of gold nanoparticles via laser ablation in liquid. Opt Laser Technol 45, 495–502 (2013). DOI: 10.1016/j.optlastec.2012.06.004 |

| [73] |

Waag F, Gökce B, Barcikowski S. Ablation target cooling by maximizing the nanoparticle productivity in laser synthesis of colloids. Appl Surf Sci 466, 647–656 (2019). DOI: 10.1016/j.apsusc.2018.10.030 |

| [74] |

Maciulevičius M, Vinčiūnas A, Brikas M, Butsen A, Tarasenka N et al. Pulsed-laser generation of gold nanoparticles with on-line surface Plasmon resonance detection. Appl Phys A 111, 289–295 (2013). DOI: 10.1007/s00339-012-7535-9 |

| [75] |

Reich S, Schönfeld P, Wagener P, Letzel A, Ibrahimkutty S et al. Pulsed laser ablation in liquids: impact of the bubble dynamics on particle formation. J Colloid Interface Sci 489, 106–113 (2017). DOI: 10.1016/j.jcis.2016.08.030 |

| [76] |

Tanabe R, Nguyen TTP, Sugiura T, Ito Y. Bubble dynamics in metal nanoparticle formation by laser ablation in liquid studied through high-speed laser stroboscopic videography. Appl Surf Sci 351, 327–331 (2015). DOI: 10.1016/j.apsusc.2015.05.030 |

| [77] |

Metwally K, Mensah S, Baffou G. Fluence threshold for photothermal bubble generation using plasmonic nanoparticles. J Phys Chem C 119, 28586–28596 (2015). DOI: 10.1021/acs.jpcc.5b09903 |

| [78] |

Liu HW, Chen F, Wang XH, Yang Q, Bian H et al. Influence of liquid environments on femtosecond laser ablation of silicon. Thin Solid Films 518, 5188–5194 (2010). DOI: 10.1016/j.tsf.2010.04.043 |

| [79] |

Delfour L, Itina TE. Mechanisms of ultrashort laser-induced fragmentation of metal nanoparticles in liquids: numerical insights. J Phys Chem C 119, 13893–13900 (2015). DOI: 10.1021/acs.jpcc.5b02084 |

| [80] |

Dakka A, Lafait J, Sella C, Berthier S, Abd-Lefdil M et al. Optical properties of Ag–TiO2 nanocermet films prepared by cosputtering and multilayer deposition techniques. Appl Opt 39, 2745–2753 (2000). DOI: 10.1364/AO.39.002745 |

| [81] |

Lau M, Barcikowski S. Quantification of mass-specific laser energy input converted into particle properties during picosecond pulsed laser fragmentation of zinc oxide and boron carbide in liquids. Appl Surf Sci 348, 22–29 (2015). DOI: 10.1016/j.apsusc.2014.07.053 |

| [82] |

Werner D, Furube A, Okamoto T, Hashimoto S. Femtosecond laser-induced size reduction of aqueous gold nanoparticles: in situ and pump−probe spectroscopy investigations revealing coulomb explosion. J Phys Chem C 115, 8503–8512 (2011). DOI: 10.1021/jp112262u |

| [83] |

Ziefuß AR, Reichenberger S, Rehbock C, Chakraborty I, Gharib M et al. Laser fragmentation of colloidal gold nanoparticles with high-intensity nanosecond pulses is driven by a single-step fragmentation mechanism with a defined Educt particle-size threshold. J Phys Chem C 122, 22125–22136 (2018). DOI: 10.1021/acs.jpcc.8b04374 |

| [84] |

Sylvestre JP, Kabashin AV, Sacher E, Meunier M. Femtosecond laser ablation of gold in water: influence of the laser-produced plasma on the nanoparticle size distribution. Appl Phys A 80, 753–758 (2005). DOI: 10.1007/s00339-004-3081-4 |

| [85] |

Brujan EA, Nahen K, Schmidt P, Vogel A. Dynamics of laser-induced cavitation bubbles near an elastic boundary. J Fluid Mech 433, 251–281 (2001). DOI: 10.1017/S0022112000003347 |

| [86] |

Harris DM, Pucci G, Prost V, Quintela Casal J, Bush JWM. Video: The merger of a bubble and a soap film. In 68th Annual Meeting of the APS Division of Fluid Dynamics - Gallery of Fluid Motion (American Physical Society, 2015). |

| [87] |

Lewis WK, Whitman WG. Principles of gas absorption. Ind Eng Chem 16, 1215–1220 (1924). DOI: 10.1021/ie50180a002 |

| [88] |

Shih CY, Streubel R, Heberle J, Letzel A, Shugaev MV et al. Two mechanisms of nanoparticle generation in picosecond laser ablation in liquids: the origin of the bimodal size distribution. Nanoscale 10, 6900–6910 (2018). DOI: 10.1039/C7NR08614H |

| [89] |

Long JY, Eliceiri M, Vangelatos Z, Rho Y, Wang LT et al. Early dynamics of cavitation bubbles generated during ns laser ablation of submerged targets. Opt Express 28, 14300–14309 (2020). DOI: 10.1364/OE.391584 |

| [90] |

Jakubith M. Grundoperationen Und Chemische Reaktionstechnik: Eine Einführung in Die Technische Chemie (Wiley-VCH, Weinheim, 1998). |

Links

Related Articles

-

Earth and Planetary Physics, DOI: 10.26464/epp2023026

-

Earth and Planetary Physics, DOI: 10.26464/epp2023026

E-mail Alert

E-mail Alert RSS

RSS