-

Abstract

Bioinspired superhydrophobic surfaces have attracted many industrial and academic interests in recent years. Inspired by unique superhydrophobicity and anisotropic friction properties of snake scale surfaces, this study explores the feasibility to produce a bionic superhydrophobic stainless steel surface via laser precision engineering, which allows the realization of directional superhydrophobicity and dynamic control of its water transportation. Dynamic mechanism of water sliding on hierarchical snake scale structures is studied, which is the key to reproduce artificially bioinspired multifunctional materials with great potentials to be used for water harvesting, droplet manipulation, pipeline transportation, and vehicle acceleration.

Keywords

-

Introduction

Many species in nature, such as plants1-4, insects2, 4-9, reptiles10-11, and marine organisms4, 12, exhibit remarkable surface functions. These precious properties are evolved over millions of years through natural selection, enabling species to thrive in extreme environments. It is well known that the vast majority of extraordinary surface properties derive from their unique hierarchical morphological features, ranging from a few tens of nanometers to hundreds of micrometers in size.

Inspiration from natural functional structures, especially famous water repellent plant leaves, like lotus leaves, a variety of artificial superhydrophobic surfaces with liquid-repellent properties have been designed and fabricated through the uniquely constructed geometrical micro/nanostructures and the chemical composition of the surface1-6. The artificial liquid-repellent surfaces exhibit certain remarkable wetting characteristics originating from a high water contact angle (CA) greater than 150° and a small water sliding angle (SA) less than 10° are of great value for a variety of applications, such as water collection6, self-cleaning13, anticorrosion14, oil/water separation15, antifreezing16, anti-fogging17, and friction reduction18. Several techniques have been developed to construct superhydrophobic surfaces, such as chemical vapor deposition19, electrospinning20, lithography21, and laser fabrication22-25. Up to now, despite the fact that artificial superhydrophobic surfaces have already revealed a significant role in both fundamental research and practical applications, continued efforts in endowing novel materials with unique properties are still highly required to realize their structural and functional integrity.

Compared with traditional surfaces with hydrophobic property, the manufacture of superhydrophobic surfaces with unique versatility has broad applications and has become a hot topic in the field of surface technology. Constructing functional superhydrophobic surfaces with high stability, versatility, flexibility, and universality have a high practical value26. For instance, Cao et al. designed a 2D MXene-reinforced robust liquid-repellent surface with self-cleaning and photothermal-actuating binary effects27. Song et al. reported a droplet-based self-propelled autonomous device composed of superhydrophobic miniboat with superhydrophilic pore28. Wang et al. acquired a wearable superhydrophobic elastomer skin with switchable wettability to switch wetting states, which enables the surface to capture and release multiple droplets in parallel29. Furthermore, some researchers have conducted research on liquid transportation. Paradisanos et al. demonstrated a methodology to fabricate a gradient wettability pattern on Si, exhibiting a high velocity for liquid spreading on a surface tension gradient in ambient conditions30. Kirner et al. reproduced the shape of the micrometre-sized tilted spikes found underneath the wings of the bark bug D. magnus, on steel surfaces to realize fast unidirectional fluid transport31. Wu et al. proposed a strategy for horizontal vibration for multimode, large-volume-range, and high-speed unidirectional microdroplet manipulation, which is ascribed to the rolling state on superhydrophobic slant microwall arrays fabricated by the femtosecond laser32. These pioneering works demonstrated the feasibility of superhydrophobic surfaces with unique multifunctionality. Therefore, developing practical and effective methods for manufacturing and functionalizing superhydrophobic surfaces will be beneficial in improving the practicability of superhydrophobic surfaces in various technical applications.

In this work, the directional transportation directivity of the bionic snake scale-like superhydrophobic surface has been reported for the first time. It was inspired from the unique superhydrophobicity and frictional anisotropy properties of the snake scales, which are promising for a wide range of scientific fields10-11. These properties are primarily due to the unique hierarchical morphological feature of the snake scales. Fabrication of snake scale-like hierarchical micro/nanostructured surfaces with unique superhydrophobicity is of great interest from the viewpoint of both experimental research and practical applications. Herein, a bionic snake scale-like superhydrophobic stainless steel surface with these feats via laser processing is reported. The study shows a novel triple inclined-beam laser ablation (IBLA) treatment at oblique incidence is implemented to fabricate the surface with three-dimensional inclined bionic snake scales that can effectively achieve the anisotropic friction. Additionally, the synergistic effect of hierarchical micro/nanostructures and the intrinsic change in the surface chemistry with the exposure to air after the laser irradiation exhibits unique superhydrophobicity along a particular direction. These characteristics collectively enable the fantastic synergy: directional water transportation. The results prescribe a method for reproducing these capabilities of snake scales in artificial materials. The technology is flexible, chemical-free, and can be easily implemented through commercial industrial laser processing systems. Accordingly, directional water transportation materials can be useful in a wide range of applications including water harvesting, droplet manipulation, pipeline transportation, and vehicle acceleration.

Materials and methods

Material

The experiment is performed on 316L stainless steel substrates with a thickness of 2 mm. Before laser ablation, the 316L stainless steel plates (50 mm × 50 mm) are polished using 800# abrasive papers and ultrasonically cleaned in deionized water to remove oxide layers and impurities.

Laser ablation

The polished samples are ablated by a Q-switched DPSS laser (Model: AVIA LX 355-20-50, Coherent) with a wavelength of 355 nm, pulse duration of 10 ns, and repetition rate up to 50 kHz. The output power can be continuously tuned with a variable attenuator. A 3D galvanometric scanner is employed to move the laser beam along X-, Y- and, Z-directions over a sample surface. The laser is focused normally and obliquely incident (45°) onto the sample surfaces through an f-theta lens, producing a focal spot diameter of about 30 µm. Programmable patterns including snake scale structures textures, randomly distributed nanoparticles, and periodic inclined cone-shaped structures are generated on the pretreated plate surfaces by laser with different laser powers (4.2 W, 0.5 W, and 0.5 W), different repetition rates (50 kHz, 30 kHz, and 30 kHz), different scanning times (1000 times, 1 time, and 1 time), and different scanning speeds (50 mm/s, 1 mm/s, and 1 mm/s) by different steps of the laser processing, respectively. Moreover, the scanning space of the second and third steps are both 30 μm. Then, the textured substrates are ultrasonically cleaned in deionized water for 10 min to remove the floating steel powder on the surface and put in the ambient air for a long time without any chemical modification treatment.

Results and discussion

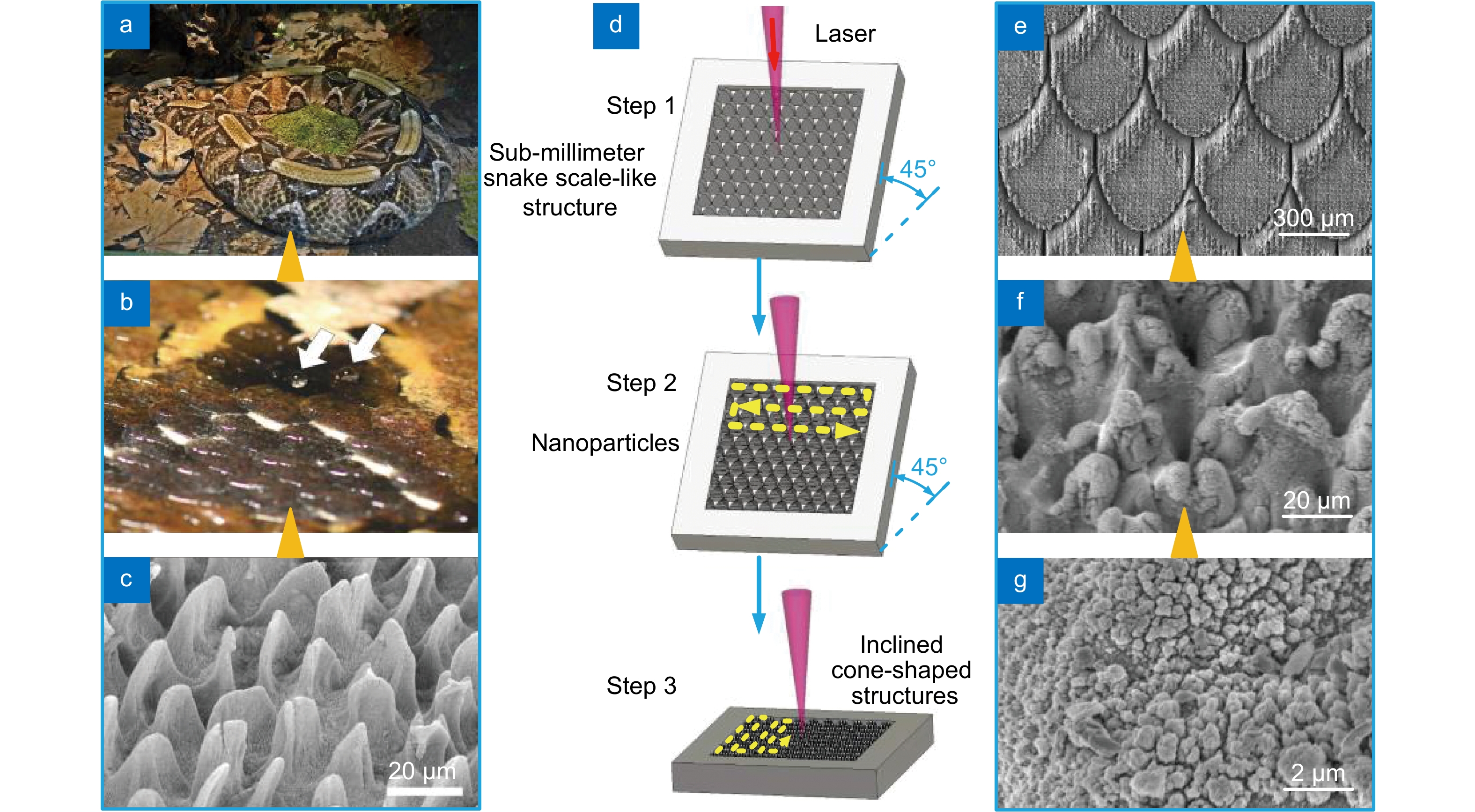

Stainless steel, which is one of the most commonly used materials in today’s society, is chosen as a substrate material for superhydrophobic surface fabrication due to its outstanding properties, such as thermal stability, chemical resistance, nontoxicity, and high mechanical strength. Laser precision engineering, which has already been proved as a valuable, versatile, and reliable technique in the fabrication of biomimetic structures and devices that feature natural materials due to its advantages of rapid, mask-free, chemical-free, and large-area micro-nanofabrication33-38. In this work, we use the new IBLA method to fabricate periodically bionic snake scale-like structured stainless steel surfaces. A Q-switched DPSS laser is employed for the processing. By using the IBLA method, the pulsed laser beam is in oblique incidence on the surface of stainless steel. Different from the conventional laser processing, the oblique beam ablation is prone to induce some unique hierarchical bionic structures. In order to realize the surface morphology of snake scales on the stainless steel surface for acquiring the unique superhydrophobicity and frictional anisotropy properties of the snake scales, we need to understand the surface morphology of snake scales in details. Figure 1(a) shows a bird’s-eye-view image of the West African Gaboon Viper (Bitis rhinoceros), which has different morphology and mechanical properties of the scales from different body sections (leading body half, middle trunk, and tailing body half) and positions (dorsal, lateral, and ventral). According to the existing literature reports, dorsal scale surfaces of Bitis rhinoceros has a high static CA beyond 160° and low SA below 20°(Fig. 1(b))10. As shown in Fig. 1(c), a tilted-view scanning electron microscopy (SEM) image of this dorsal scale surfaces of Bitis rhinoceros shows a hierarchical micro/nanostructure consisting of microscopic inclined cone-shaped structures. Therefore, inspired by this special hierarchical micro/nanostructure, a highly bionic snake scale-like three-level hierarchical micro/nanostructured surface via the IBLA method is thus fabricated. The principle and preparation process of the snake scale-like artificial surface are shown in Fig. 1(d). First, the sub-millimeter snake scale-like structure array is fabricated on the stainless steel by nanosecond laser oblique ablation. In order to introduce anisotropy into the snake scale-like structure array, the snake scale-like structure array is designed to be tilted cross stacked arrangement as same as the real snake skin, and the distances between adjacent snake scales in the transverse and longitudinal directions are designed to be different. Then, the nanoscale nanoparticles and the microscale inclined cone-shaped structures are ablated on each unit of snake scale-like structure array by the second and third steps of laser processing for acquiring superhydrophobicity and promoting anisotropy. As a result, the highly bionic three-level hierarchical snake scale-like structure array can be achieved. Figures 1(e)-1(g) show the SEM images of the as-prepared sample surface morphology with different magnifications. The high magnification SEM images indicate that the size of the unit of snake scale-like structure array is about 500 μm and the surface of the unit is rather rough, composed of inclined cone-shaped microstructures. It is worth noting that the surfaces of these microstructures are not smooth, with plenty of nanoparticles that are densely and unevenly distributed on the surface of each micro-cone. These sub-millimeter, micro- and nanoscale structures are crucial for obtaining directivity and superwetting characteristics that are similar to what is observed in dorsal scale surfaces of Bitis rhinoceros.

![Figure 1. Schematic illustration and fabrication process of a snake scale-like surface via the IBLA method. (a) The photographs of the West African Gaboon Viper (Bitis rhinoceros). (b) Photographic image of the dorsal skin of a living individual of Bitis rhinoceros after sprinkling with water. Figure reproduced with permission from ref.10, Copyright 2014, PLOS Publishing. (c) SEM image of the hierarchical structures of the dorsal scale surfaces of Bitis rhinoceros. Figure reproduced with permission from ref.10, Copyright 2014, PLOS Publishing. (d) Schematic illustration of the manufacture of snake scale-like artificial surface by IBLA technique. (e−g) SEM images of the as-prepared sample surfaces at different magnifications.]()

Schematic illustration and fabrication process of a snake scale-like surface via the IBLA method. (a) The photographs of the West African Gaboon Viper (Bitis rhinoceros). (b) Photographic image of the dorsal skin of a living individual of Bitis rhinoceros after sprinkling with water. Figure reproduced with permission from ref.10, Copyright 2014, PLOS Publishing. (c) SEM image of the hierarchical structures of the dorsal scale surfaces of Bitis rhinoceros. Figure reproduced with permission from ref.10, Copyright 2014, PLOS Publishing. (d) Schematic illustration of the manufacture of snake scale-like artificial surface by IBLA technique. (e−g) SEM images of the as-prepared sample surfaces at different magnifications.

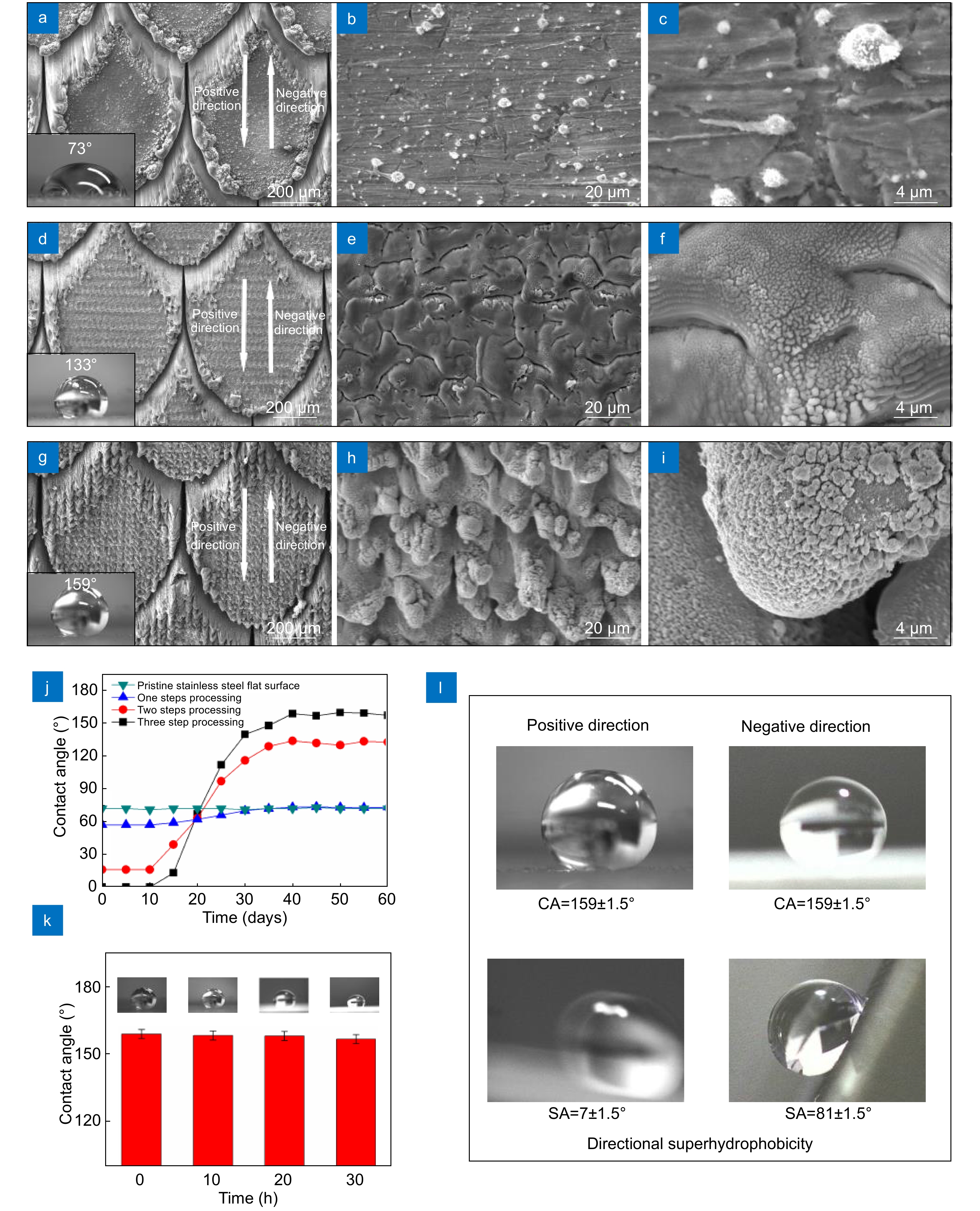

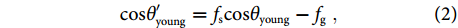

To quantificationally investigate the influence of the three-level hierarchical structures of the snake scale-like surfaces on directional superhydrophobicity, liquid-repellent property measurement has been carried out for the laser fabricated snake scale-like surfaces with different hierarchical structures, and the sliding property of the as-prepared surfaces has been tested both along and against the snake scale direction. Each measured value is averaged over three locations. As shown in Fig. 2, the SEM images of micro/nanostructured snake scale-like surfaces with different hierarchical structures at different amplified scales have been shown. It can be seen that the overall surfaces are periodic arrangement of snake scales and oblique grooves with different hierarchical structures by one step, two steps, and three steps of the laser precision engineering, respectively (Figs. 2(a), 2(d) and 2(g)). Enlarged images demonstrate that the surface roughness of the as-prepared samples becomes larger with the increase of processing steps (Figs. 2(b), 2(e) and 2(h)), and through the three steps of the laser processing, the microscale inclined cone-shaped structures are created on each unit of the snake scale-like structure array. As shown in Figs. 2(c), 2(f) and 2(i), the surface is gradually adhered by more and more particulate melt protrusions with the increase in processing steps, and the size of particulate melt protrusions getting smaller and smaller to the nanoscale. These results indicate that the as-prepared surface by the three steps of the laser processing have similar three-level hierarchical micro/nanostructures with those on the real snake scale. The surfaces with different hierarchical structures exhibit different wetting properties, and the CA (5 µL water droplet) measured parallel to surfaces with different hierarchical structures are about 73°, 133°, and 159° as shown in the bottom-left corner of Figs. 2(a), 2(d) and 2(g), respectively. Considering the fact that the CA of the pristine stainless steel with a flat surface is only about 72°, the IBLA fabricated hierarchical micro/nanostructures are considered to be an essential factor to gain the hydrophobicity. Figure 2(j) depicts the time-dependence of CAs for the as-prepared surfaces with different hierarchical structures by different steps of the laser processing when they are exposed to air. Before the laser treatment, all the bare stainless steel surfaces were hydrophilic. Once ablated by laser, the fresh stainless steel surfaces immediately exhibit hydrophilic or even superhydrophilic behavior, and the water droplet can even fully spread out when it touches the laser-induced rough surface. It is unable to acquire a CA value as the droplet is almost completely penetrated into the grooves. This phenomenon is well pronounced within 10 days after the laser ablation. According to the Wenzel theory, the increase of surface roughness leads to an amplification effect of surface wettability39.

![Figure 2. Micro/nanostructures, and wetting behavior of the superhydrophobic surfaces with different hierarchical structures by different steps of the laser processing. (a) SEM images of the hierarchical structures of the snake scale-like array by one step laser processing; the inset shows that the CA of the water droplet is 73°. (b, c) SEM images of (a) at different magnified scales. (d) SEM images of the hierarchical structures of the snake scale-like array by two steps laser processing; the inset shows that the CA of the water droplet is 133°. (e, f) SEM images corresponding to (d) at different magnified scales. (g) SEM images of the hierarchical structures of the snake scale-like array by three steps laser processing; the inset shows that the CA of the water droplet is 159°. (h, i) SEM images corresponding to (g) at different magnified scales. (j) Time-dependence of CAs for the hierarchical surfaces by different steps laser processing exposed to air. (k) Superhydrophilicity of the complete three-level hierarchical surfaces in 30 h. (l) Wetting results (CAs and SAs) on the surface corresponding to opposite directions, respectively.]()

Micro/nanostructures, and wetting behavior of the superhydrophobic surfaces with different hierarchical structures by different steps of the laser processing. (a) SEM images of the hierarchical structures of the snake scale-like array by one step laser processing; the inset shows that the CA of the water droplet is 73°. (b, c) SEM images of (a) at different magnified scales. (d) SEM images of the hierarchical structures of the snake scale-like array by two steps laser processing; the inset shows that the CA of the water droplet is 133°. (e, f) SEM images corresponding to (d) at different magnified scales. (g) SEM images of the hierarchical structures of the snake scale-like array by three steps laser processing; the inset shows that the CA of the water droplet is 159°. (h, i) SEM images corresponding to (g) at different magnified scales. (j) Time-dependence of CAs for the hierarchical surfaces by different steps laser processing exposed to air. (k) Superhydrophilicity of the complete three-level hierarchical surfaces in 30 h. (l) Wetting results (CAs and SAs) on the surface corresponding to opposite directions, respectively.

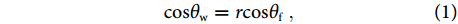

cosθw=rcosθf, where r > 1 is surface roughness parameter; θf and θw represent CAs for the flat and rough surfaces, respectively. Equation (1) reveals that with the enhancement of surface roughness, a hydrophilic surface becomes more hydrophilic and a hydrophobic surface becomes more hydrophobic. Therefore, at early stage of CA evolution, the fresh stainless steel surfaces exhibit very small contact angles due to the increment of roughness. Another reason for the observed superhydrophilicity is the change of surface chemical compositions before/after the laser ablation, which will be explained in detail in the mechanism section later. Observing contact angle curve in Fig. 2(j), it is noted that when the laser ablated surfaces are exposed to air, their surface hydrophilicity decreases and the CA increases over time. Between Day 11 and Day 30, the CA of surfaces by the two steps and three steps of laser processing witnessed a sharp increase from 0° to 127° and 0° to 139°, respectively. It is noted that fresh surfaces reach hydrophobic behaviors. With the time exposed to air increases, only the surface CA by the three steps of laser processing exceeds 150°, and the CA of 159° is obtained when the three steps laser-induced surface is exposed to ambient air for 40 days. Then, CA gradually remains in a relatively stable state of 159 ± 2°, which can be characterized as a typical superhydrophobic surface. Thus, it can be concluded that after the laser ablation and exposure to air, only the three steps laser-induced three-level hierarchical micro/nanostructured surface shows superhydrophobicity. Additionally, as shown in Fig. 2(k), the as-prepared surface by the three steps of laser processing retains superhydrophobicity for a long time (at least 30 hours) in contact with water until the droplets on the surface evaporate. Meanwhile, the superhydrophobicity is also maintained by re-measurement at the location where the droplets evaporate.

Like the snake skin, such a snake scale-like three-level hierarchical micro/nanostructured surface displays superhydrophobic anisotropic sliding. As shown in Fig. 2(l) and Movie S1 (see Supplementary information), in the negative direction (CA = 159° ± 1.5°, SA = 81° ± 1.5°, measured parallel to the surfaces), SA is larger than that in the positive direction (CA = 159° ± 1.5°, SA = 7° ± 1.5°, measured parallel to the surfaces), positive direction and negative direction are the measured directions as labeled in Figs. 2(a), 2(d) and 2(g). These results demonstrate that anisotropic superhydrophobic and directional sliding states can be realized by this snake scale-like three-level hierarchical micro/nanostructured surface. Herein, the surface chemical modification has not been utilized in the preparation, which means that the unique three-level hierarchical micro/nanostructures mainly induce the directional wetting performance.

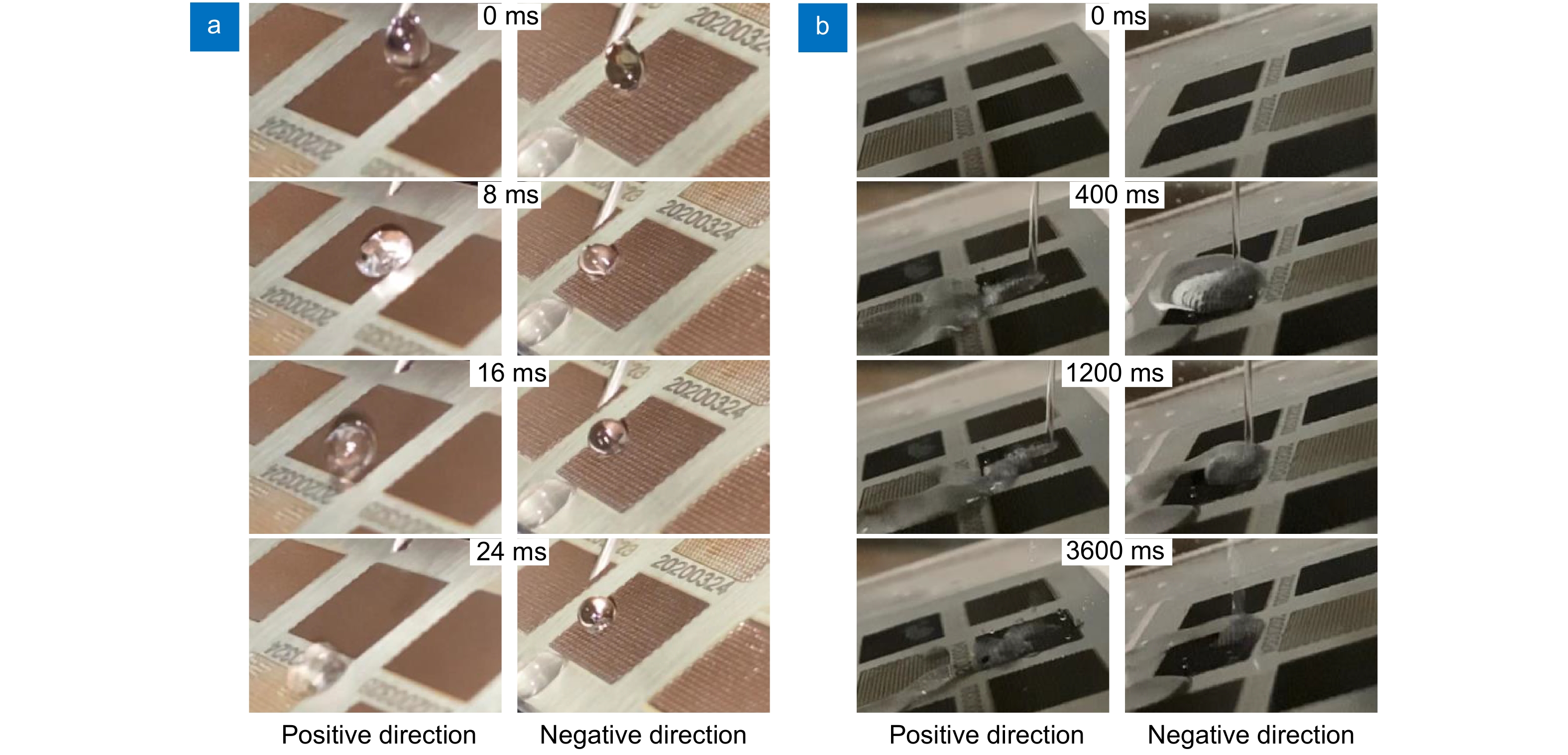

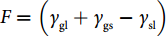

To evaluate the directional control of the water-sliding ability, the sliding process is monitored in real time, the positive and negative directions sliding states of the snake scale-like surface are measured (Fig. 3 and Movies S2 to S5, Supplementary information). As shown in Fig. 3(a), the sample is first tilted 30° along the positive direction, droplets (about 20 µL) are randomly added at different locations, all the droplets instantaneously rolling off the as-prepared surface along the positive direction. Then, the sample turns 180° to the negative direction and it still tilted at 30°. All the added droplets are adhered on it. The motion of water flowing along the positive and negative directions is also studied when the as-prepared surface is tilted at the same angle. Under the action of gravity force, the water flow is accelerated at the moment leaving the syringe and falls to the as-prepared surface. In the experiment, the surface is tilted 30°. Figure 3(b) shows the motion of water flow on the anisotropic surface at different time. Water flows smoothly along the positive direction of the superhydrophobic surface. Under the same conditions, only when the water accumulates and the gravitational potential energy exceeds the adhesion, the water begins to flow along the negative direction of the superhydrophobic surface. Moreover, when the gravitational potential energy drops smaller than the adhesion force by lowering the height of water flow, instead of flowing down along the negative direction of the as-prepared surface, most of the water flow is guided horizontally to both sides by the surface until it exceeds the superhydrophobic surface boundary. More details of the droplets and water flow moving along the two directions are shown in Movies S2 to S5. In these Movies, it is easy to observe the difference between the droplets/flow sliding along the positive and negative directions of the as-prepared surface. The experimental result shows that the adhesion of the liquid sliding against the positive direction is larger than that along the positive direction. Therefore, it can be concluded that different droplet transportation paths can be achieved by using the snake scale-like three-level hierarchical micro/nanostructures to control the water-sliding directivity. Furthermore, it needs to be stressed that droplet transportation just represents one function, the surface with such an ability can be easily extended to other microstructure-dependent functional applications, such as pipeline transportation, vehicle acceleration, and other fluidic devices.

![Figure 3. Directional water transport property and water repellency of the superhydrophobic surface. (a) Time sequences of snapshots of a water droplet rolling on the as-prepared surface along the positive and negative directions. See Movies S2 and S3. (b) Time sequences of snapshots of water stream flowing through the as-prepared surface along the positive and negative directions. See Movies S4 and S5. The as-prepared surfaces in (a) and (b) are tilted 30°.]()

Directional water transport property and water repellency of the superhydrophobic surface. (a) Time sequences of snapshots of a water droplet rolling on the as-prepared surface along the positive and negative directions. See Movies S2 and S3. (b) Time sequences of snapshots of water stream flowing through the as-prepared surface along the positive and negative directions. See Movies S4 and S5. The as-prepared surfaces in (a) and (b) are tilted 30°.

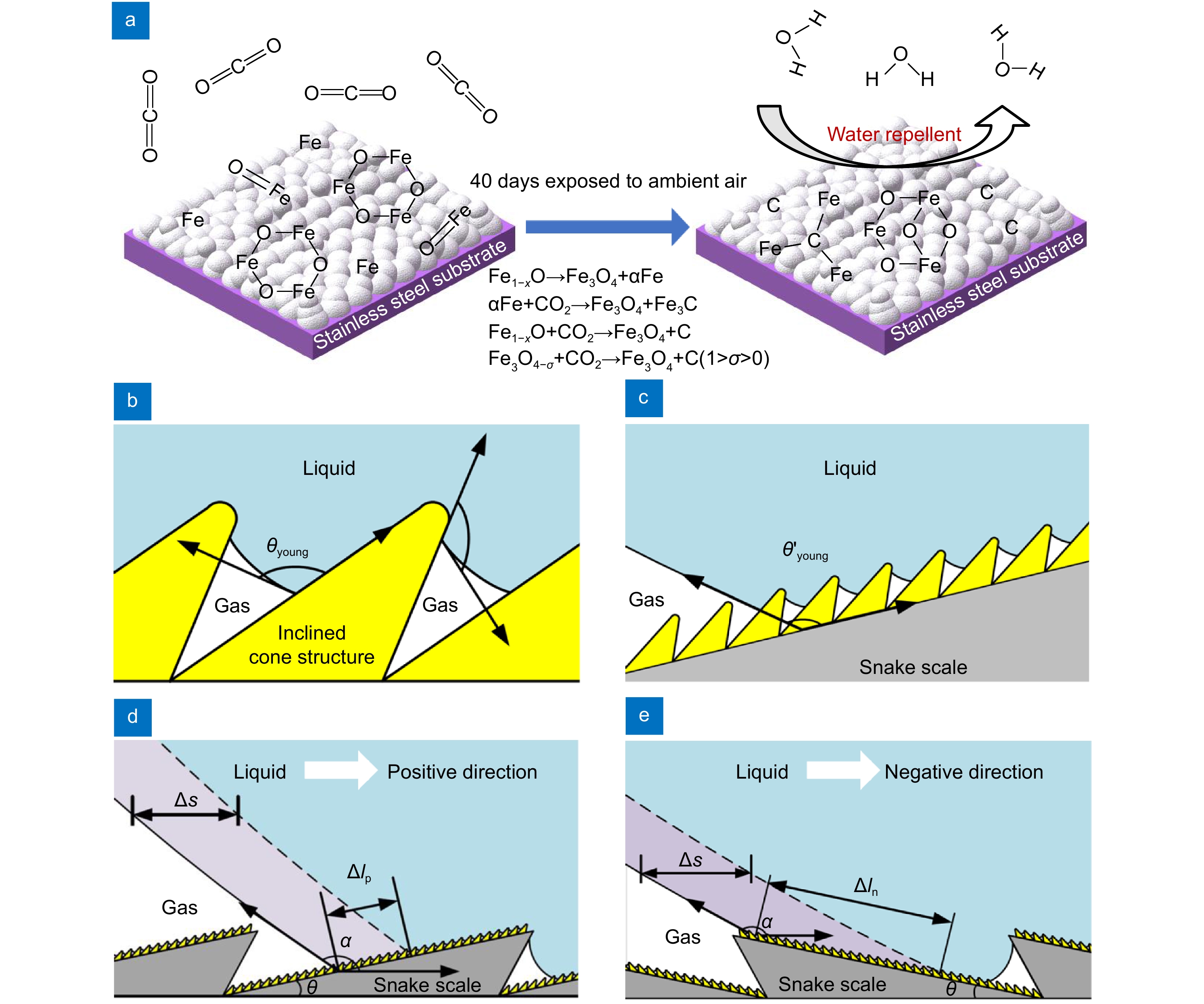

From the above experimental results, it can be seen that the hierarchies of surface micro/nanostructures (three-level hierarchical snake scale-like micro/nanostructures) and suitable arrangement of the micro/nanostructures (tilted cross stacked arrangement) are important for the smart wetting performance, which can be explained as follows. As a three-level hierarchical structure, the snake scale-like structure consists of large snake scale structures in sub-millimeter scale and inclined cone-shaped structures in microscale, decorated with nanoparticles (Fig. 4). First of all, at the nanoscale (Fig. 4(a)), pulsed laser ablation produces active magnetite (Fe3O4−σ with 0<σ<1) on the surface of stainless steel, which has been identified as an environment capable of dissociating and absorbing carbon dioxide40-43. Over time, the carbon dioxide decomposition reaction is sustained and slow under ambient air with nonpolar carbon deposited on the nanoparticles (over 1 month). The efficient amount of low surface energy of carbon and its compound which were deposited on the surface could reduce the surface energy of the as-prepared surface. Thus, the intrinsic contact angle θyoung of the snake scale-like surface can be increased. Secondly, to combine nanoparticles with microscale inclined cone-shaped structures, there is an opportunity to achieve the high apparent contact angle

θ′young and the Cassie–Baxter state simultaneously (Figs. 4(b) and 4(c), the micro/nanostructures can form air pockets to trap air and lead to the surface superhydrophobicity44).![Figure 4. Mechanism of directional water transport. (a) Schematic illustration of the molecule/atom interaction mechanism. (b) The intrinsic contact angle on snake scale. (c) The apparent contact angle on snake scale. (d) Schematic illustration of liquid flow in the positive direction of snake scale-like structures. (e) Schematic illustration of liquid flow in the negative direction of snake scale-like structures.]()

Mechanism of directional water transport. (a) Schematic illustration of the molecule/atom interaction mechanism. (b) The intrinsic contact angle on snake scale. (c) The apparent contact angle on snake scale. (d) Schematic illustration of liquid flow in the positive direction of snake scale-like structures. (e) Schematic illustration of liquid flow in the negative direction of snake scale-like structures.

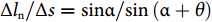

cosθ′young=fscosθyoung−fg, where

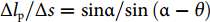

fs andfg are the fractions of the solid surface and air in contact with water, respectively (i.e.,fs+fg=1 ). Based on the above explanation, it would be easy to understand the transform of surface wetting to superhydrophobic. Meanwhile, after the introduction of the sub-millimeter scale snake scale-like structures with an inclination angle (Figs. 4(d) and 4(e)), the as-prepared surface acquires anisotropic friction characteristics. When a water droplet is wetting and rolling on the surface, the solid/liquid contact area increases in the forward and decreases in the backward directions. The resistance of the droplet mainly comes from the adhesion force when the liquid detaches from the solid in the backward direction. The friction force of the droplet is related to the detaching area of the solid/liquid interface when the liquid moves a unit distance, and the friction force is the product of interfacial energy and the detaching area divided by the unit moving distanceF=(γgl+γgs−γsl) ×k×Δl/Δs 45. Here γ is the interfacial energy,k×Δl is the detaching area, k is the width of the liquid flow,Δl is the detaching distance of the solid-liquid interface, andΔs is the unit moving distance of the liquid droplet. When the liquid droplet rolls in the positive or negative direction of the snake scale-like structures, the ratio ofΔl toΔs is different due to different inclination angles.Δlp/Δs=sinα/sin(α−θ) ,Δln/Δs=sinα/sin(α+θ) , whereθ is the inclination angle of the snake scale-like structure, andα is the contact angle. As a result, the detaching distance of the solid/liquid interfaceΔln (along the negative direction) is larger than the detaching distance of the solid/liquid interfaceΔlp (along the positive direction). Therefore, the liquid droplet rolls in the negative direction, the friction force is larger than that in the positive direction. Meanwhile, when the water flow is against the positive direction of the as-prepared surface and the impulse of the flow is large enough, it is easy for the water flow to break the air pockets at the interface and the trapped air in the oblique grooves is replaced by water. This causes the transition of the superhydrophobic surface from Cassie–Baxter to Wenzel state, and the motion state of water flow changes from rolling state to pinning state and produces high adhesion. Therefore, the snake scale-like surface with particular three-level hierarchical micro/nanostructures can realize superhydrophobic and directional tunable water sliding.Moreover, based on theoretical analyses, the rolling movement of water droplets along the positive and negative directions of the snake scale surface under the action of gravity force is simulated. Simulation of the flowfield is performed using a VOF method with ANSYS Fluent, which is a numerical technique used to track the fluid-fluid interface in computational fluid dynamics46. The volume of the water droplet is 20 μL and the tilt angle of the snake scale-like surface is 30°. Figures 5(a) and 5(b) show the simulation models as the droplets rolling in the positive direction and negative direction, respectively. The green, white, and blue areas represent water droplets, air, and substrate, respectively. To simulate the fluid interface between the air and the water. The edge of the water droplet is used as the initial interface. The edge of the rough structure of the substrate is used as the wetting wall. The CA of the wetting wall is 159°. The transient results of the water droplet moving in 16 ms are calculated. As shown in Figs. 5(c), 5(e) and 5(g), the change of color scale on the left represents the change of the velocity vector, when the water droplet drops on the snake scale-like surface which is tilted 30° along the positive direction, the droplet moves about 5 mm to the left at 16 ms. Correspondingly, when the snake scale-like surface is tilted 30° along the negative direction, the droplets adhere to the surface and do not move, as shown in Figs. 5(d), 5(f) and 5(h). More results of simulation at different directions are presented in Movies S6 and S7 (see Supplementary information). Under the equal inclination angle of the surface, the simulation results show that the rolling distance of droplet along the positive direction is greater than that along the negative direction, indicating that the friction force at the solid−liquid interface along the positive direction is less than that in the negative direction. It is theoretically proved that the snake scale-like surface can realize directional tunable water sliding.

![Figure 5. Simulated regimes of the droplet sliding on the snake scale-like surface along the positive and negative directions. (a, b) Local magnification of the simulation structures. (c, e, g) Time sequences of simulations of a water droplet rolling on the as-prepared surface along the positive direction. See Movie S6, Supplementary information. (d, f, h) Time sequences of simulations of water droplet rolling on the as-prepared surface along the negative direction. See Movie S7, Supplementary information.]()

Simulated regimes of the droplet sliding on the snake scale-like surface along the positive and negative directions. (a, b) Local magnification of the simulation structures. (c, e, g) Time sequences of simulations of a water droplet rolling on the as-prepared surface along the positive direction. See Movie S6, Supplementary information. (d, f, h) Time sequences of simulations of water droplet rolling on the as-prepared surface along the negative direction. See Movie S7, Supplementary information.

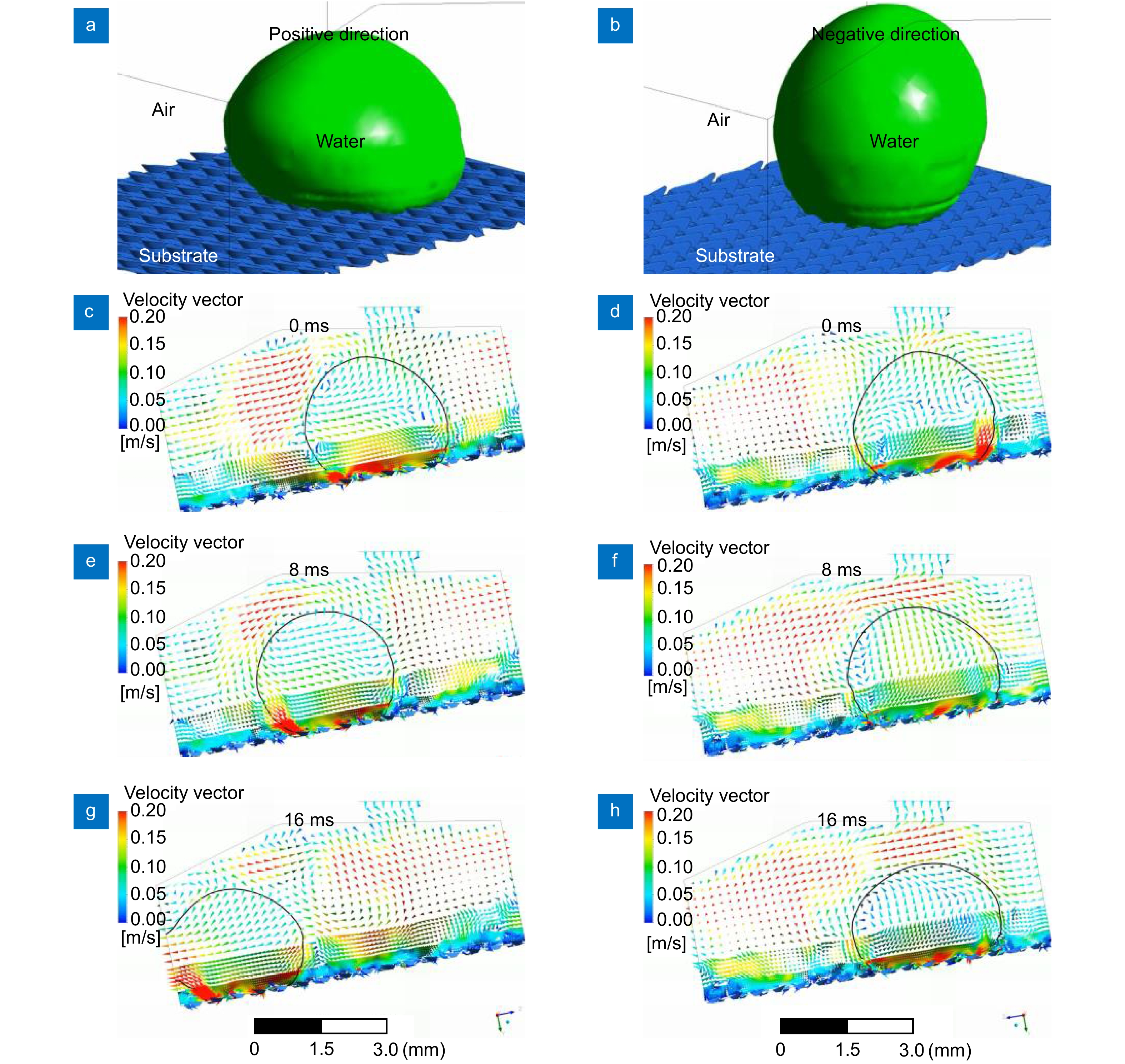

Based on both the excellent superhydrophobicity and high directional performance of the snake scale-like structure surface, it is highly expected that coupling this structure with ship surfaces to form a “ship skin” could further realize directional reducing/increasing friction. The dynamic response between the solid and liquid interfaces under continuous water flow is studied. In particular, stainless steel plates textured with snake scale-like structures are designed as skins covered both sides of a ship model to study the directional movement, the water circulation system provides a continuous water flow, and friction force occurs when the surface of the ship moves under the continuous water flow (Fig. 6(a)). As shown in Fig. 6(b) and Movie S8 (see Supplementary information), the ship moves rapidly under the continuous water flow along the positive direction of the as-prepared surface, which is mostly attributed to the directional superhydrophobicity caused by the inclined hierarchical snake scale-like structures. As the water flow is along the positive direction, it is difficult for the water to enter the grooves because of the existence of the scales and the inclined grooves. Additionally, the moving states of the ship can be manipulated by rotating the ship 180 degrees (Fig. 6(c)). The results show that when other conditions are the same as that before the ship rotates, the ship hardly moves with the flow of water, it is because the friction force of the as-prepared surface in the negative direction is larger than that in the positive direction, and the air pockets at the interface are broken by the water flow, which causes the increase of surface adhesion force, as explained before. The snapshots of the movement of the ship confirm that the directional superhydrophobic behaviors are achieved by the snake scale-like structures fabricated by the laser processing.

![Figure 6. Application of the surface as a “ship skin” for controllable navigational direction. (a) The simulated model and the real object of the ship, and the schematic illustration of the water circulation system. (b, c) Time sequences of snapshots of an armoured ship moving under the continuous water flow along the positive and negative directions of the as-prepared surface. See Movie S8, Supplementary information.]()

Application of the surface as a “ship skin” for controllable navigational direction. (a) The simulated model and the real object of the ship, and the schematic illustration of the water circulation system. (b, c) Time sequences of snapshots of an armoured ship moving under the continuous water flow along the positive and negative directions of the as-prepared surface. See Movie S8, Supplementary information.

Conclusions

In conclusion, we present a novel bionic snake scale-like three-level hierarchical micro/nanostructured surface to realize superhydrophobicity and directional water sliding. To demonstrate the unique directional superhydrophobicity controlling, a stainless steel surface with snake scale-like three-level hierarchical micro/nanostructures is fabricated by laser ablation. Experimental results reveal that the CA can be achieved as high as 159°. Moreover, the adhesion force and the SA show strong dependence on the direction of the structures of the surface, giving the possibility of controllable superhydrophobic states along the positive and negative directions. Based on these unique properties, a “ship skin” for directional movement study is proposed. This work can provide new understandings toward solving the problems of superhydrophobic surfaces with directional wettability, and control the water mobility for a wide range of potential applications, such as water harvesting, droplet manipulation, pipeline transportation, and vehicle acceleration.

Acknowledgements

This work was supported by the Advanced Remanufacturing and Technology Centre (ARTC) under its RIE2020 Advanced Manufacturing and Engineering (AME) IAF PP Grant (No. A19C2a0019).

Competing interests

The authors declare no competing financial interests.

-

References

[1] Feng L, Li S, Li Y, Li H, Zhang L et al. Super-hydrophobic surfaces: from natural to artificial. Adv Mater 14, 1857–1860 (2002).

DOI: 10.1002/adma.200290020[2] Feng XJ, Jiang L. Design and creation of superwetting/antiwetting surfaces. Adv Mater 18, 3063–3078 (2006).

DOI: 10.1002/adma.200501961[3] Zorba V, Stratakis E, Barberoglou M, Spanakis E, Tzanetakis P et al. Biomimetic artificial surfaces quantitatively reproduce the water repellency of a lotus leaf. Adv Mater 20, 4049–4054 (2008).

DOI: 10.1002/adma.200800651[4] Sanchez C, Arribart H, Guille MMG. Biomimetism and bioinspiration as tools for the design of innovative materials and systems. Nat Mater 4, 277–288 (2005).

DOI: 10.1038/nmat1339[5] Gao XF, Jiang L. Water-repellent legs of water striders. Nature 432, 36 (2004).

DOI: 10.1038/432036a[6] Zheng YM, Bai H, Huang ZB, Tian XL, Nie FQ et al. Directional water collection on wetted spider silk. Nature 463, 640–643 (2010).

DOI: 10.1038/nature08729View full references list -

Cited by

Periodical cited type(75)

1. Xie, C., Yin, J., Hong, M. Enhancement of laser-textured surface mechanochemical robustness via electromagnetic induction heating and water quenching. Colloids and Surfaces A Physicochemical and Engineering Aspects, 2025. DOI:10.1016/j.colsurfa.2025.137529 2. Li, G., Yang, Z., Wu, W. et al. Extreme wetting metallic devices: Structures, fabrication, applications and prospects. Progress in Materials Science, 2025. DOI:10.1016/j.pmatsci.2025.101505 3. Wu, J., Hu, W., Zhang, Y. et al. Investigation of Wear Behavior for Innovative Cutting Tool in Machining AISI 304 Stainless Steel. Eng, 2025, 6(9): 248. DOI:10.3390/eng6090248 4. Sun, M., Fu, H., Lei, H. et al. A Multi-Curvature Soft Gripper Based on Segmented Variable Stiffness Structure Inspired by Snake Scales. Soft Robotics, 2025, 12(4): 399-409. DOI:10.1089/soro.2024.0043 5. Zhang, Z., Jia, M., Zhang, T. et al. Efficient prediction of long-term wettability evolution in laser-textured surfaces using short-term data and cyclic deep learning. Optics and Laser Technology, 2025. DOI:10.1016/j.optlastec.2025.112558 6. Yang, H., Wang, K., Liu, Y. et al. Borehole Radar Experiment in a 7500 m Deep Well. Sensors, 2025, 25(10): 2991. DOI:10.3390/s25102991 7. Xiao, Q., Wang, X., Wang, Y. et al. Beyond smoothness: the art of surface texturing battling against friction. International Journal of Extreme Manufacturing, 2025, 7(2): 022014. DOI:10.1088/2631-7990/ad9c01 8. Robinson, N.J., Lazo-Wasem, E.A., Rojas, L. et al. Microdermatoglyphic patterns in scutes are highly conserved among sea turtle species. Herpetology Notes, 2025.

9. Yu, J., Gu, G., Qu, C. et al. Triple-enhanced Raman scattering sensor based on superhydrophobic/-philic microsphere platform and heating evaporation assisted for high-sensitivity detection. Sensors and Actuators B Chemical, 2024. DOI:10.1016/j.snb.2024.136332 10. Luo, P., Xu, H., Lu, H. et al. Patternable, high-precision, controllable wettability copper layers for 3D resin-based weather-resistant electronics and 3D liquid manipulation. Materials Horizons, 2024, 12(3): 845-861. DOI:10.1039/d4mh00756e 11. Wang, Z., Huang, L., Gao, J. et al. Leaf Vein-Inspired Superhydrophilic Microchannels for Sustainable Fog Collection. ACS Applied Materials and Interfaces, 2024, 16(39): 53252-53260. DOI:10.1021/acsami.4c11883 12. Zhang, D., Xiu, S., Wang, K. et al. SiC-7A52 brazed joint reinforced by femtosecond laser surface modification. Journal of Manufacturing Processes, 2024. DOI:10.1016/j.jmapro.2024.07.062 13. Liu, Y., Zhang, Y., Guo, C. et al. A multi-task learning network based on the Transformer network for airborne electromagnetic detection imaging and denoising. Journal of Geophysics and Engineering, 2024, 21(3): 1056-1070. DOI:10.1093/jge/gxae054 14. Yang, K., Tang, J., Huang, J. et al. Hydrophobic and Tribological Properties of Biomimetic Interfaces. Coatings, 2024, 14(5): 529. DOI:10.3390/coatings14050529 15. Zhu, D., Li, Q., He, X. et al. Preparation of highly dewetted porous steel for shallow water AUV based on laser ablation method. Applied Surface Science, 2024. DOI:10.1016/j.apsusc.2023.159261 16. Liu, M., Hua, J., Du, X. Smart materials for light control of droplets. Nanoscale, 2024, 16(18): 8820-8827. DOI:10.1039/d3nr05593k 17. Li, B., Jiang, L., Li, X. et al. Self-propelled Leidenfrost droplets on femtosecond-laser-induced surface with periodic hydrophobicity gradient. International Journal of Extreme Manufacturing, 2024, 6(2): 025502. DOI:10.1088/2631-7990/ad18fb 18. Liu, S., Ma, Y., Long, J. et al. Patterned Manipulated Surface Based on Femtosecond Laser with Adjustable Wetting Speed and Directional Fluid Delivery. ACS Applied Materials and Interfaces, 2024, 16(9): 11973-11983. DOI:10.1021/acsami.3c15626 19. Chen, X., Sun, S., Wang, D. et al. Construction of superhydrophobic surfaces with different water adhesion on the low-temperature steels by picosecond laser processing. Surface and Coatings Technology, 2024. DOI:10.1016/j.surfcoat.2023.130340 20. Gour, R., Baliyan, N., Pal, A. et al. Animal Tribology. Applications of Biotribology in Biomedical Systems, 2024. DOI:10.1007/978-3-031-58327-8_8 21. Gao, J., Song, Y., Huang, L. et al. Laser-Textured Hybrid Brass Pattern Array Surface for High-Efficiency Fog Collection. Langmuir, 2023, 39(49): 18143-18151. DOI:10.1021/acs.langmuir.3c03056 22. Yang, D., Guo, C., Wang, F. et al. PICGAN: Conditional adversarial neural network-based permittivity inversions for ground penetrating radar data. Journal of Applied Geophysics, 2023. DOI:10.1016/j.jappgeo.2023.105164 23. Deng, Q., Yin, K., Wang, L. et al. One Droplet toward Efficient Alcohol Detection Using Femtosecond Laser Textured Micro/Nanostructured Surface with Superwettability. Small Methods, 2023, 7(9): 2300290. DOI:10.1002/smtd.202300290 24. Yang, Y., Ren, Z., Chen, W. et al. Superhydrophobic wire-cotton woven porous material with excellent durability for emulsion separation. Separation and Purification Technology, 2023. DOI:10.1016/j.seppur.2023.124175 25. Zhao, J., Ji, K., Chen, Q. et al. Resistance reduction of patterned surface inspired by cuticle structure of Achalinus spinalis. Friction, 2023, 11(7): 1359-1370. DOI:10.1007/s40544-022-0694-6 26. Yin, K., Wang, L., Deng, Q. et al. Efficient water boiling evaporation via a laser-architected superhydrophilic, underwater superaerophobic, and high infrared emissivity interface. Chemical Engineering Journal, 2023. DOI:10.1016/j.cej.2023.143336 27. Liu, Y., Qi, X., Deng, X. et al. Snake Scale-Inspired Poly(vinylidene fluoride)/Ti3CNTx@Polypyrrole Coatings for Ultrawide-Bandwidth Microwave and Visible Light Absorption. ACS Applied Materials and Interfaces, 2023, 15(23): 28491-28502. DOI:10.1021/acsami.3c03250 28. Yue, B., Zhu, G., Chang, Z. et al. Wettability Variation of Different Nickel Surface Morphologies Prepared by Electrodeposition and UV Illumination. Journal of Materials Engineering and Performance, 2023, 32(11): 5015-5027. DOI:10.1007/s11665-022-07463-3 29. Jiang, Q., Zhang, Y., Xu, Y. et al. Extremely High-Quality Periodic Structures on ITO Film Efficiently Fabricated by Femtosecond Pulse Train Output from a Frequency-Doubled Fabry–Perot Cavity. Nanomaterials, 2023, 13(9): 1510. DOI:10.3390/nano13091510 30. Zhao, Y., Wang, S., Yu, W. et al. Simulation and Experimental Study of Laser Processing NdFeB Microarray Structure. Micromachines, 2023, 14(4): 808. DOI:10.3390/mi14040808 31. Nurhayati, A.. Classification of animal biomimetic characteristics for tribological applications. Jurnal Tribologi, 2023.

32. Yuan, Y., Tian, L.-C., Guo, C. et al. Spectral diagnosis of an arc jet actuator | [电弧射流激励器光谱诊断研究]. Chinese Optics, 2023, 16(2): 296-304. DOI:10.37188/CO.2022-0097 33. Chen, Z., Zhou, R., Hong, M. Enhanced anti-icing performance via bio-inspired papaver radicatum structuring. Journal of Materials Research and Technology, 2023. DOI:10.1016/j.jmrt.2023.02.035 34. He, X., Liu, Y., Zhan, H. et al. Bidirectional Underwater Drag Reduction on Bionic Flounder Two-Tier Structural Surfaces. Biomimetics, 2023, 8(1): 116. DOI:10.3390/biomimetics8010116 35. Yuan, Y., Yan, Z., Zhang, P. et al. A Broadband Achromatic Dielectric Planar Metalens in Mid-IR Range. Photonic Sensors, 2023, 13(1): 230126. DOI:10.1007/s13320-022-0667-4 36. Zhang, Z., Yang, Z., Zhao, Z. et al. Multimodal Deep-Learning Framework for Accurate Prediction of Wettability Evolution of Laser-Textured Surfaces. ACS Applied Materials and Interfaces, 2023, 15(7): 10261-10272. DOI:10.1021/acsami.2c21439 37. Zhao, S., Du, H., Ma, Z. et al. Hierarchical composite structure to simultaneously realize superior superhydrophobicity and anti-reflection. Applied Surface Science, 2023. DOI:10.1016/j.apsusc.2022.155652 38. Peng, F., Guo, C., Chang, Z. et al. A Nine-Level Inverter with Adjustable Turn-Off Time for Helicopter Transient Electromagnetic Detection. Sensors, 2023, 23(4): 1950. DOI:10.3390/s23041950 39. Wang, H., Zhang, D., Wei, Z. et al. Enhancing Al2O3-7A52 brazed joints by femtosecond laser surface machining of periodic alumina structure. Processing and Application of Ceramics, 2023, 17(4): 436-445. DOI:10.2298/PAC2304436W 40. Jiang, Q., Chen, L., Liu, J. et al. Periodic transparent nanowires in ITO film fabricated via femtosecond laser direct writing. Opto Electronic Science, 2023, 2(1): 220002. DOI:10.29026/oes.2023.220002 41. Han, D.-D., Zhang, Y.-L., Chen, Z.-D. et al. Carnivorous plants inspired shape-morphing slippery surfaces. Opto Electronic Advances, 2023, 6(1): 210163. DOI:10.29026/oea.2023.210163 42. Du, S., Zhang, C., Sun, W. et al. Application of laser microfabrication in medical equipment | [激光微细加工技术在医疗器材领域的应用]. Guangdian Gongcheng Opto Electronic Engineering, 2023, 50(3): 220306. DOI:10.12086/oee.2023.220306 43. Yu, J., Yang, H., Wu, J. et al. Ultrafast laser fabrication of surface-enhanced Raman scattering sensors | [超快激光制造表面增强拉曼散射传感器]. Guangdian Gongcheng Opto Electronic Engineering, 2023, 50(3): 220333. DOI:10.12086/oee.2023.220333 44. Zhang, C., Wen, T., Liu, Z. et al. Research and application advances of photo-responsive droplet manipulation functional surface | [光响应液滴操控功能表面研究及应用进展]. Guangdian Gongcheng Opto Electronic Engineering, 2023, 50(3): 220326. DOI:10.12086/oee.2023.220326 45. Wang, L., Yin, K., Deng, Q. et al. Wetting Ridge-Guided Directional Water Self-Transport. Advanced Science, 2022, 9(34): 2204891. DOI:10.1002/advs.202204891 46. Chen, Z., Yuan, G., Zhou, R. et al. Rich CuO Nanowires Fabrication via Laser Post-Treatment of Laser-Textured Copper Substrate. Inorganics, 2022, 10(12): 236. DOI:10.3390/inorganics10120236 47. Yin, K., Wang, L., Deng, Q. et al. Femtosecond Laser Thermal Accumulation-Triggered Micro-/Nanostructures with Patternable and Controllable Wettability Towards Liquid Manipulating. Nano Micro Letters, 2022, 14(1): 97. DOI:10.1007/s40820-022-00840-6 48. Zhao, Y.-Z., Hong, M.-H. Stainless steel anisotropic superhydrophobic surfaces fabrication with inclined cone array via laser ablation and post annealing treatment | [基于激光烧蚀和后退火处理的斜锥结构阵列各向异性不锈钢超疏水表面制备]. Journal of Central South University, 2022, 29(10): 3261-3269. DOI:10.1007/s11771-022-5145-z 49. Shao, K., Jiang, S., Hu, Y. et al. Bioinspired Lubricated Slippery Magnetic Responsive Microplate Array for High Performance Multi-Substance Transport. Advanced Functional Materials, 2022, 32(40): 2205831. DOI:10.1002/adfm.202205831 50. Wang, Q.-H., Wang, H.-X. Laser surface functionalization to achieve extreme surface wetting conditions and resultant surface functionalities | [激光表面功能化实现极端表面润湿特性及相应表面功能]. Journal of Central South University, 2022, 29(10): 3217-3247. DOI:10.1007/s11771-022-5140-4 51. Yuan, Y., Zhang, Y., Guo, C. et al. Study on Performance of a Miniaturized High Density Inductively Coupled Plasma Generator | [小型化高密度可调控电感耦合等离子体发生器性能研究]. Dianzi Keji Daxue Xuebao Journal of the University of Electronic Science and Technology of China, 2022, 51(5): 715-720. DOI:10.12178/1001-0548.2021356 52. Yu, J., Wu, J., Yang, H. et al. Extremely Sensitive SERS Sensors Based on a Femtosecond Laser-Fabricated Superhydrophobic/-philic Microporous Platform. ACS Applied Materials and Interfaces, 2022, 14(38): 43877-43885. DOI:10.1021/acsami.2c10381 53. Wang, M., Long, J., Liu, Y. et al. A Superhydrophilic Silicon Surface Enhanced by Multiscale Hierarchical Structures Fabricated by Laser Direct Writing. Langmuir, 2022, 38(36): 11015-11021. DOI:10.1021/acs.langmuir.2c01633 54. Yin, J., Yan, H., Dunzhu, G. et al. General Strategy toward Laser Single-Step Generation of Multiscale Anti-Reflection Structures by Marangoni Effect. Micromachines, 2022, 13(9): 1491. DOI:10.3390/mi13091491 55. Song, Y., Hu, Y., Zhang, Y. et al. Flexible Tri-switchable Wettability Surface for Versatile Droplet Manipulations. ACS Applied Materials and Interfaces, 2022, 14(32): 37248-37256. DOI:10.1021/acsami.2c12890 56. Wu, Z., Wu, J., Wang, L. et al. A hierarchical porous membrane achieved by femtosecond laser scribing with water-repellent, highly breathable and photo-thermal ability. Optics and Laser Technology, 2022. DOI:10.1016/j.optlastec.2022.108171 57. Wang, Y., Wang, S., Meng, J. Recent progress of bioinspired interfacial materials towards efficient and sustainable scale resistance. Giant, 2022. DOI:10.1016/j.giant.2022.100116 58. Yuan, Y., Zhang, Y., Guo, C. et al. Optical analysis method for fast plasma characterization of high-speed miniaturized synthetic jet. Chinese Optics Letters, 2022, 20(7): 073001. DOI:10.3788/COL202220.073001 59. Wang, L., Yin, K., Zhu, Z. et al. Femtosecond laser engraving micro/nanostructured poly (ether-ether-ketone) surface with superhydrophobic and photothermal ability. Surfaces and Interfaces, 2022. DOI:10.1016/j.surfin.2022.102013 60. Yuan, Y., Zhang, Y., Zhao, Q. et al. Numerical study on the characteristics of an arc jet plasma actuator | [电弧射流激励器工作特性仿真研究]. Qiangjiguang Yu Lizishu High Power Laser and Particle Beams, 2022, 34(6): 065003. DOI:10.11884/HPLPB202234.210527 61. Wang, X.L., Wang, H.Y., Liu, Y.D. et al. Improvement of multi-functional properties by fabricating micro-pillar arrays structures on zirconium alloy surface. Science China Technological Sciences, 2022, 65(6): 1243-1252. DOI:10.1007/s11431-021-2024-5 62. Zhang, D., Liu, R., Ji, S. et al. Hierarchical WO3- xUltrabroadband Absorbers and Photothermal Converters Grown from Femtosecond Laser-Induced Periodic Surface Structures. ACS Applied Materials and Interfaces, 2022, 14(20): 24046-24058. DOI:10.1021/acsami.2c04523 63. Chen, J., Lu, X., Li, Z. et al. Anisotropy of material removal during laser-induced plasma assisted ablation of sapphire. Ceramics International, 2022, 48(10): 13880-13889. DOI:10.1016/j.ceramint.2022.01.272 64. Li, J., Yang, D., Guo, C. et al. Application of GPR System With Convolutional Neural Network Algorithm Based on Attention Mechanism to Oil Pipeline Leakage Detection. Frontiers in Earth Science, 2022. DOI:10.3389/feart.2022.863730 65. Chen, Z., Zhou, R., Yan, H. et al. Bioinspired robust top-perforated micro-conical array of TC4 surface fabricated by pulsed laser ablation for enhanced anti-icing property. Journal of Materials Science, 2022, 57(19): 8890-8903. DOI:10.1007/s10853-022-07194-9 66. Johnson, A.P., Sabu, C., Nivitha, K.P. et al. Bioinspired and biomimetic micro- and nanostructures in biomedicine. Journal of Controlled Release, 2022. DOI:10.1016/j.jconrel.2022.02.013 67. Jiao, Z., Han, X., Zhou, H. et al. Laser fabrication of light/voltage-responsive slippery liquid-infused porous substrate (SLIPS) | [光/电响应型超滑表面的激光加工制备]. Guangdian Gongcheng Opto Electronic Engineering, 2022, 49(2): 210356. DOI:10.12086/oee.2022.210356 68. Zhang, Y., Hu, Y., Xu, B. et al. Robust Underwater Air Layer Retention and Restoration on Salvinia-Inspired Self-Grown Heterogeneous Architectures. ACS Nano, 2022, 16(2): 2730-2740. DOI:10.1021/acsnano.1c09669 69. Zhu, X., Pan, Z., Yang, W. et al. Study on multi-layered CFRP patch bonding joint based on laser 3D engraving technology | [基于激光三维雕刻的CFRP多梯层挖补胶接接头加工技术研究]. Guangdian Gongcheng Opto Electronic Engineering, 2022, 49(1): 210314. DOI:10.12086/oee.2022.210314 70. Ouyang, X., Xie, Z., Zhang, M. et al. Laser-induced periodic surface structure for microscale anti-counterfeiting structural colors | [基于激光诱导表面周期结构的微纳防伪结构色]. Guangdian Gongcheng Opto Electronic Engineering, 2022, 49(1): 210320. DOI:10.12086/oee.2022.210320 71. Yang, Q., Cheng, Y., Fang, Z. et al. The preparation and applications of bio-inspired slippery surface by femtosecond laser micro-nano manufacturing | [仿生超滑表面的飞秒激光微纳制造及应用]. Guangdian Gongcheng Opto Electronic Engineering, 2022, 49(1): 210326. DOI:10.12086/oee.2022.210326 72. Warrender, J.M.. Hydrophobic and Hydrophilic Surfaces Created by Nanosecond Laser Structuring. Journal of Laser Micro Nanoengineering, 2022, 17(3): 184-193. DOI:10.2961/jlmn.2022.03.2008 73. He, Y., Yin, J., Chen, S. et al. Preparation and application of superhydrophobic surfaces: from fluorine to nature. Proceedings of SPIE the International Society for Optical Engineering, 2022. DOI:10.1117/12.2638634 74. Yang, Y., Zhang, Y., Hu, Y. et al. Femtosecond Laser Regulated Ultrafast Growth of Mushroom-Like Architecture for Oil Repellency and Manipulation. Nano Letters, 2021, 21(21): 9301-9309. DOI:10.1021/acs.nanolett.1c03506 75. Lin, Z., Hong, M. Femtosecond Laser Precision Engineering: From Micron, Submicron, to Nanoscale. Ultrafast Science, 2021. DOI:10.34133/2021/9783514 Other cited types(0)

-

Author Information

-

Supplementary Information

TitleActions -

Copyright

Open Access. © The Author(s). This article is licensed under a Creative Commons Attribution 4.0 International License. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/. -

About this Article

Cite this Article

Yizhe Zhao, Yilin Su, Xuyan Hou, et al. Directional sliding of water: biomimetic snake scale surfaces. Opto-Electronic Advances 4, 210008 (2021). DOI: 10.29026/oea.2021.210008Download CitationArticle History

- Received Date January 20, 2021

- Accepted Date February 27, 2021

- Available Online April 01, 2021

- Published Date April 05, 2021

Article Metrics

Article Views(16336) PDF Downloads(1551)

E-mail Alert

E-mail Alert RSS

RSS