| Citation: | Zhang L, Tong LM. A bioinspired flexible optical sensor for force and orientation sensing. Opto-Electron Adv 6, 230051 (2023). doi: 10.29026/oea.2023.230051 |

News & Views Open Access

A bioinspired flexible optical sensor for force and orientation sensing

-

Abstract

Flexible optical sensors have been an emerging paradigm for applications in robotics, healthcare, and human–machine interfaces due to their high sensitivity, fast response, and anti-electromagnetic interference. Recently, Marques reports a bioinspired multifunctional flexible optical sensor (BioMFOS), achieving a forces sensitivity of 13.28 μN, and a spatial resolution of 0.02 mm. The BioMFOS has a small dimension (around 2 cm) and a light weight (0.8 g), making it suitable for wearable application and clothing integration. As proof-of-concept demonstrations, monitoring of finger position, trunk movements, and respiration rate are realized, implying their prominent applications in remote healthcare, intelligent robots, assistance devices teleoperation, and human-machine interfaces. -

-

References

[1] Kim J, Campbell AS, de Ávila BEF, Wang J. Wearable biosensors for healthcare monitoring. Nat Biotechnol 37, 389–406 (2019). doi: 10.1038/s41587-019-0045-y [2] Shih B, Shah D, Li JX, Thuruthel TG, Park YL et al. Electronic skins and machine learning for intelligent soft robots. Sci Robot 5, eaaz9239 (2020). doi: 10.1126/scirobotics.aaz9239 [3] Ko SH, Rogers J. Functional materials and devices for XR (VR/AR/MR) applications. Adv Funct Mater 31, 2106546 (2021). doi: 10.1002/adfm.202106546 [4] Guo JJ, Yang CX, Dai QH, Kong LJ. Soft and stretchable polymeric optical waveguide-based sensors for wearable and biomedical applications. Sensors 19, 3771 (2019). doi: 10.3390/s19173771 [5] Zhang L, Tang Y, Tong LM. Micro-/Nanofiber optics: merging photonics and material science on nanoscale for advanced sensing technology. iScience 23, 100810 (2020). doi: 10.1016/j.isci.2019.100810 [6] Zhang L, Pan J, Zhang Z, Wu H, Yao N et al. Ultrasensitive skin-like wearable optical sensors based on glass micro/nanofibers. Opto-Electron Adv 3, 190022 (2020). doi: 10.29026/oea.2020.190022 [7] Yu W, Yao N, Pan J, Fang W, Li X et al. Highly sensitive and fast response strain sensor based on evanescently coupled micro/nanofibers. Opto-Electron Adv 5, 210101 (2022). doi: 10.29026/oea.2022.210101 [8] Tang Y, Liu HT, Pan J, Zhang Z, Xu Y et al. Optical micro/nanofiber-enabled compact tactile sensor for hardness discrimination. ACS Appl Mater Interfaces 13, 4560–4566 (2021). doi: 10.1021/acsami.0c20392 [9] Ma SQ, Wang XY, Li P, Yao N, Xiao JL et al. Optical micro/nano fibers enabled smart textiles for human–machine interface. Adv Fiber Mater 4, 1108–1117 (2022). doi: 10.1007/s42765-022-00163-6 [10] Tang Y, Yu LT, Pan J, Yao N, Geng WD et al. Optical nanofiber skins for multifunctional humanoid tactility. Adv Intell Syst 5, 2200203 (2023). doi: 10.1002/aisy.202200203 [11] Guo JJ, Niu MX, Yang CX. Highly flexible and stretchable optical strain sensing for human motion detection. Optica 4, 1285–1288 (2017). doi: 10.1364/OPTICA.4.001285 [12] Harnett CK, Zhao HC, Shepherd RF. Stretchable optical fibers: threads for strain-sensitive textiles. Adv Mater Technol 2, 1700087 (2017). doi: 10.1002/admt.201700087 [13] Leber A, Cholst B, Sandt J, Vogel N, Kolle M. Stretchable thermoplastic elastomer optical fibers for sensing of extreme deformations. Adv Funct Mater 29, 1802629 (2019). doi: 10.1002/adfm.201802629 [14] Xu PA, Mishra AK, Bai H, Aubin CA, Zullo L et al. Optical lace for synthetic afferent neural networks. Sci Robot 4, eaaw6304 (2019). doi: 10.1126/scirobotics.aaw6304 [15] Chen MX, Wang Z, Li KW, Wang XD, Wei L. Elastic and stretchable functional fibers: a review of materials, fabrication methods, and applications. Adv Fiber Mater 3, 1–13 (2021). doi: 10.1007/s42765-020-00057-5 [16] Zhao HC, O’Brien K, Li S, Shepherd RF. Optoelectronically innervated soft prosthetic hand via stretchable optical waveguides. Sci Robot 1, eaai7529 (2016). doi: 10.1126/scirobotics.aai7529 [17] Bai HD, Li S, Barreiros J, Tu YQ, Pollock CR et al. Stretchable distributed fiber-optic sensors. Science 370, 848–852 (2020). doi: 10.1126/science.aba5504 [18] Van Meerbeek IM, De Sa CM, Shepherd RF. Soft optoelectronic sensory foams with proprioception. Sci Robot 3, eaau2489 (2018). doi: 10.1126/scirobotics.aau2489 [19] Zhou JY, Shao Q, Tang C, Qian F, Lu TQ et al. Conformable and compact multiaxis tactile sensor for human and robotic grasping via anisotropic waveguides. Adv Mater Technol 7, 2200595 (2022). doi: 10.1002/admt.202200595 [20] Leal-Junior A, Avellar L, Biazi V, Soares MS, Frizera A et al. Multifunctional flexible optical waveguide sensor: on the bioinspiration for ultrasensitive sensors development. Opto-Electron Adv 5, 210098 (2022). doi: 10.29026/oea.2022.210098 -

Access History

Article Metrics

-

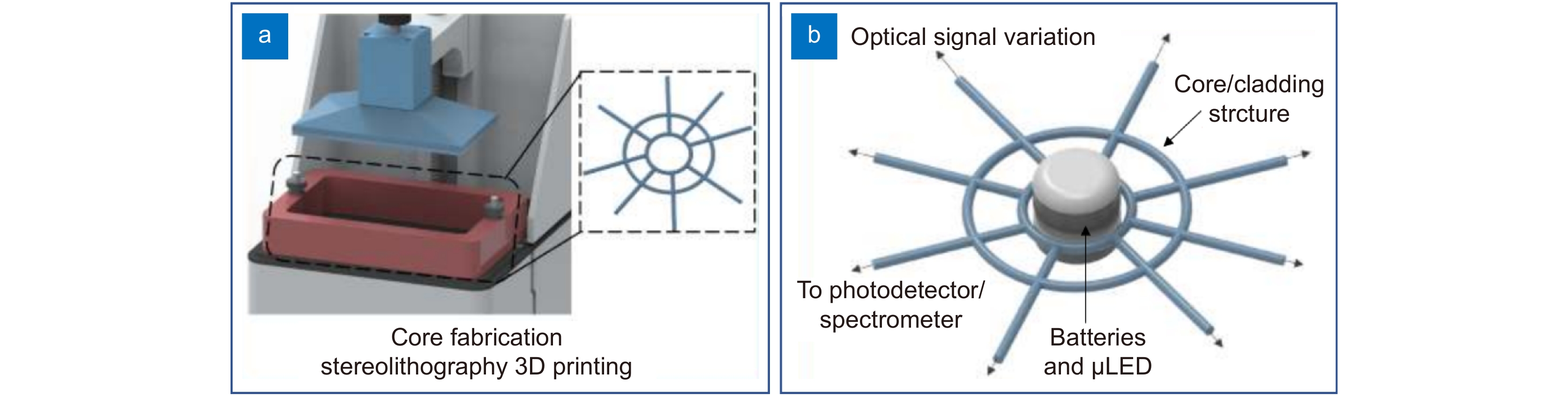

Figure 1.

(a) Schematic representation of the core/cladding fabrication using stereolithography 3D printing technique. (b) Representation of the batteries and μLED assembly in the structure.

E-mail Alert

E-mail Alert RSS

RSS

DownLoad:

DownLoad: