| Citation: | Zhang H, Feng L, Wang FY, Liu MZ, Zhang YY et al. Janus aramid nanofiber aerogel incorporating plasmonic nanoparticles for high-efficiency interfacial solar steam generation. Opto-Electron Adv 6, 220061 (2023). doi: 10.29026/oea.2023.220061 |

Janus aramid nanofiber aerogel incorporating plasmonic nanoparticles for high-efficiency interfacial solar steam generation

-

Abstract

Interfacial solar steam generation (ISSG) is a novel and potential solution to global freshwater crisis. Here, based on a facile sol-gel fabrication process, we demonstrate a highly scalable Janus aramid nanofiber aerogel (JANA) as a high-efficiency ISSG device. JANA performs near-perfect broadband optical absorption, rapid photothermal conversion and effective water transportation. Owning to these features, efficient desalination of salty water and purification of municipal sewage are successfully demonstrated using JANA. In addition, benefiting from the mechanical property and chemical stability of constituent aramid nanofibers, JANA not only possesses outstanding flexibility and fire-resistance properties, but its solar steaming efficiency is also free from the influences of elastic deformations and fire treatments. We envision JANA provides a promising platform for mass-production of high-efficiency ISSG devices with supplementary capabilities of convenient transportation and long-term storage, which could further promote the realistic applications of ISSG technology. -

-

References

[1] Schewe J, Heinke J, Gerten D, Haddeland I, Arnell NW et al. Multimodel assessment of water scarcity under climate change. Proc Natl Acad Sci USA 111, 3245–3250 (2014). doi: 10.1073/pnas.1222460110 [2] Elimelech M, Phillip WA. The future of seawater desalination: energy, technology, and the environment. Science 333, 712–717 (2011). doi: 10.1126/science.1200488 [3] Fritzmann C, Löwenberg J, Wintgens T, Melin T. State-of-the-art of reverse osmosis desalination. Desalination 216, 1–76 (2007). doi: 10.1016/j.desal.2006.12.009 [4] El-Dessouky HT, Ettouney HM, Al-Roumi Y. Multi-stage flash desalination: present and future outlook. Chem Eng J 73, 173–190 (1999). doi: 10.1016/S1385-8947(99)00035-2 [5] Wang WB, Aleid S, Shi YF, Zhang CL, Li RY et al. Integrated solar-driven PV cooling and seawater desalination with zero liquid discharge. Joule 5, 1873–1887 (2021). doi: 10.1016/j.joule.2021.05.010 [6] Li RY, Shi Y, Wu MC, Hong S, Wang P. Photovoltaic panel cooling by atmospheric water sorption-evaporation cycle. Nat Sustain 3, 636–643 (2020). doi: 10.1038/s41893-020-0535-4 [7] Yao HZ, Zhang PP, Huang YX, Cheng HH, Li C et al. Highly efficient clean water production from contaminated air with a wide humidity range. Adv Mater 32, 1905875 (2020). doi: 10.1002/adma.201905875 [8] Tao P, Ni G, Song CY, Shang W, Wu JB et al. Solar-driven interfacial evaporation. Nat Energy 3, 1031–1041 (2018). doi: 10.1038/s41560-018-0260-7 [9] Wang ZX, Horseman T, Straub AP, Yip NY, Li DY et al. Pathways and challenges for efficient solar-thermal desalination. Sci Adv 5, eaax0763 (2019). doi: 10.1126/sciadv.aax0763 [10] Mi BX. Interfacial solar evaporator for brine treatment: the importance of resilience to high salinity. Natl Sci Rev 8, nwab118 (2021). doi: 10.1093/nsr/nwab118 [11] Feng L, Huo PC, Liang YZ, Xu T. Photonic metamaterial absorbers: morphology engineering and interdisciplinary applications. Adv Mater 32, 1903787 (2020). doi: 10.1002/adma.201903787 [12] Wang ZH, Liu YM, Tao P, Shen QC, Yi N et al. Bio-inspired evaporation through plasmonic film of nanoparticles at the air-water interface. Small 10, 3234–3239 (2014). doi: 10.1002/smll.201401071 [13] Zhou L, Tan YL, Ji DX, Zhu B, Zhang P et al. Self-assembly of highly efficient, broadband plasmonic absorbers for solar steam generation. Sci Adv 2, e1501227 (2016). doi: 10.1126/sciadv.1501227 [14] Zhou L, Tan YL, Wang JY, Xu WC, Yuan Y et al. 3D self-assembly of aluminium nanoparticles for plasmon-enhanced solar desalination. Nat Photonics 10, 393–398 (2016). doi: 10.1038/nphoton.2016.75 [15] Bae K, Kang GM, Cho SK, Park W, Kim K et al. Flexible thin-film black gold membranes with ultrabroadband plasmonic nanofocusing for efficient solar vapour generation. Nat Commun 6, 10103 (2015). doi: 10.1038/ncomms10103 [16] Shi Y, Ilic O, Atwater HA, Greer JR. All-day fresh water harvesting by microstructured hydrogel membranes. Nat Commun 12, 2797 (2021). doi: 10.1038/s41467-021-23174-0 [17] Qi DP, Liu Y, Liu YB, Liu ZY, Luo YF et al. Polymeric membranes with selective solution-diffusion for intercepting volatile organic compounds during solar-driven water remediation. Adv Mater 32, 2004401 (2020). doi: 10.1002/adma.202004401 [18] Shao Y, Jiang ZP, Zhang YJ, Wang T, Zhao P et al. All-Poly(ionic liquid) Membrane-Derived porous carbon membranes: Scalable synthesis and application for photothermal conversion in seawater desalination. ACS Nano 12, 11704–11710 (2018). doi: 10.1021/acsnano.8b07526 [19] Liu FH, Zhao BY, Wu WP, Yang HY, Ning YS et al. Low cost, robust, environmentally friendly geopolymer-mesoporous carbon composites for efficient solar powered steam generation. Adv Funct Mater 28, 1803266 (2018). doi: 10.1002/adfm.201803266 [20] Li JL, Wang XY, Lin ZH, Xu N, Li XQ et al. Over 10 kg m−2 h−1 evaporation rate enabled by a 3D interconnected porous carbon foam. Joule 4, 928–937 (2020). doi: 10.1016/j.joule.2020.02.014 [21] Ren HY, Tang M, Guan BL, Wang KX, Yang JW et al. Hierarchical graphene foam for efficient omnidirectional solar-thermal energy conversion. Adv Mater 29, 1702590 (2017). doi: 10.1002/adma.201702590 [22] Zhang PP, Liu F, Liao QH, Yao HZ, Geng HY et al. A microstructured graphene/poly(N-isopropylacrylamide) membrane for intelligent solar water evaporation. Angew Chem Int Ed 57, 16343–16347 (2018). doi: 10.1002/anie.201810345 [23] Liang HX, Liao QH, Chen N, Liang Y, Lv GQ et al. Thermal efficiency of solar steam generation approaching 100% through capillary water transport. Angew Chem Int Ed 58, 19041–19046 (2019). doi: 10.1002/anie.201911457 [24] Yang H, Sun YH, Peng MW, Cai MJ, Zhao B et al. Tailoring the salt transport flux of solar evaporators for a highly effective salt-resistant desalination with high productivity. ACS Nano 16, 2511–2520 (2022). doi: 10.1021/acsnano.1c09124 [25] Xu N, Hu XZ, Xu WC, Li XQ, Zhou L et al. Mushrooms as efficient solar steam-generation devices. Adv Mater 29, 1606762 (2017). doi: 10.1002/adma.201606762 [26] Li W, Chen ZJ, Yu HP, Li J, Liu SX. Wood-derived carbon materials and light-emitting materials. Adv Mater 33, 2000596 (2021). doi: 10.1002/adma.202000596 [27] Guo YH, Lu HY, Zhao F, Zhou XY, Shi W et al. Biomass-derived hybrid hydrogel evaporators for cost-effective solar water purification. Adv Mater 32, 1907061 (2020). doi: 10.1002/adma.201907061 [28] Cao SS, Rathi P, Wu XH, Ghim D, Jun YS et al. Cellulose nanomaterials in interfacial evaporators for desalination: a "natural" choice. Adv Mater 33, 2000922 (2021). doi: 10.1002/adma.202000922 [29] Li N, Qiao LF, He JT, Wang SX, Yu LM et al. Solar-driven interfacial evaporation and self-powered water wave detection based on an all-cellulose monolithic design. Adv Funct Mater 31, 2008681 (2021). doi: 10.1002/adfm.202008681 [30] Wu XH, Cao SS, Ghim D, Jiang QS, Singamaneni S et al. A thermally engineered polydopamine and bacterial nanocellulose bilayer membrane for photothermal membrane distillation with bactericidal capability. Nano Energy 79, 105353 (2021). doi: 10.1016/j.nanoen.2020.105353 [31] Liu Y, Xiong J, Li AL, Wang RW, Wang LM et al. Plasmonic silver nanoparticle-decorated electrospun nanofiber membrane for interfacial solar vapor generation. Text Res J 91, 2624–2634 (2021). doi: 10.1177/00405175211014966 [32] Guo YH, Zhou XY, Zhao F, Bae J, Rosenberger B et al. Synergistic energy nanoconfinement and water activation in hydrogels for efficient solar water desalination. ACS Nano 13, 7913–7919 (2019). doi: 10.1021/acsnano.9b02301 [33] Lu Y, Fan DQ, Wang YD, Xu HL, Lu CH et al. Surface patterning of two-dimensional nanostructure-embedded photothermal hydrogels for high-yield solar steam generation. ACS Nano 15, 10366–10376 (2021). doi: 10.1021/acsnano.1c02578 [34] Zhou XY, Guo YH, Zhao F, Shi W, Yu GH. Topology-controlled hydration of polymer network in hydrogels for solar-driven wastewater treatment. Adv Mater 32, 2007012 (2020). doi: 10.1002/adma.202007012 [35] Guo YH, Zhao F, Zhou XY, Chen ZC, Yu GH. Tailoring nanoscale surface topography of hydrogel for efficient solar vapor generation. Nano Lett 19, 2530–2536 (2019). doi: 10.1021/acs.nanolett.9b00252 [36] Zang LL, Sun LG, Zhang SC, Finnerty C, Kim A et al. Nanofibrous hydrogel-reduced graphene oxide membranes for effective solar-driven interfacial evaporation and desalination. Chem Eng J 422, 129998 (2021). doi: 10.1016/j.cej.2021.129998 [37] Dong XY, Cao LT, Si Y, Ding B, Deng HB. Cellular structured CNTs@SiO2 nanofibrous aerogels with vertically aligned vessels for salt-resistant solar desalination. Adv Mater 32, 1908269 (2020). doi: 10.1002/adma.201908269 [38] Yang MQ, Tan CF, Lu WH, Zeng KY, Ho GW. Spectrum tailored defective 2D semiconductor nanosheets aerogel for full-spectrum-driven photothermal water evaporation and photochemical degradation. Adv Funct Mater 30, 2004460 (2020). doi: 10.1002/adfm.202004460 [39] Wu X, Robson ME, Phelps JL, Tan JS, Shao B et al. A flexible photothermal cotton-CuS nanocage-agarose aerogel towards portable solar steam generation. Nano Energy 56, 708–715 (2019). doi: 10.1016/j.nanoen.2018.12.008 [40] Zhao X, Peng LM, Tang CY, Pu JH, Zha XJ et al. All-weather-available, continuous steam generation based on the synergistic photo-thermal and electro-thermal conversion by MXene-based aerogels. Mater Horiz 7, 855–865 (2020). doi: 10.1039/C9MH01443H [41] Zhao L, Bhatia B, Zhang LN, Strobach E, Leroy A et al. A passive high-temperature high-pressure solar steam generator for medical sterilization. Joule 4, 2733–2745 (2020). doi: 10.1016/j.joule.2020.10.007 [42] Xu Y, Guo ZZ, Wang J, Chen ZH, Yin JC et al. Harvesting solar energy by flowerlike carbon cloth nanocomposites for simultaneous generation of clean water and electricity. ACS Appl Mater Interfaces 13, 27129–27139 (2021). doi: 10.1021/acsami.1c07091 [43] Xiong ZC, Zhu YJ, Qin DD, Chen FF, Yang RL. Flexible fire-resistant photothermal paper comprising ultralong hydroxyapatite nanowires and carbon nanotubes for solar energy-driven water purification. Small 14, 1803387 (2018). doi: 10.1002/smll.201803387 [44] Zhou B, Han GJ, Zhang Z, Li ZY, Feng YZ et al. Aramid nanofiber-derived carbon aerogel film with skin-core structure for high electromagnetic interference shielding and solar-thermal conversion. Carbon 184, 562–570 (2021). doi: 10.1016/j.carbon.2021.08.067 [45] Zhang H, Feng L, Liang YZ, Xu T. An ultra-flexible plasmonic metamaterial film for efficient omnidirectional and broadband optical absorption. Nanoscale 11, 437–443 (2019). doi: 10.1039/C8NR05276J [46] Cao KQ, Siepermann CP, Yang M, Waas AM, Kotov NA et al. Reactive aramid nanostructures as high-performance polymeric building blocks for advanced composites. Adv Funct Mater 23, 2072–2080 (2013). doi: 10.1002/adfm.201202466 [47] Kimling J, Maier M, Okenve B, Kotaidis V, Ballot H et al. Turkevich method for gold nanoparticle synthesis revisited. J Phys Chem B 110, 15700–15707 (2006). doi: 10.1021/jp061667w [48] Zhao YY, Ren XL, Zheng ML, Jin F, Liu J et al. Plasmon-enhanced nanosoldering of silver nanoparticles for high-conductive nanowires electrodes. Opto-Electron Adv 4, 200101 (2021). doi: 10.29026/oea.2021.200101 [49] Zhao F, Zhou XY, Shi Y, Qian X, Alexander M et al. Highly efficient solar vapour generation via hierarchically nanostructured gels. Nat Nanotechnol 13, 489–495 (2018). doi: 10.1038/s41565-018-0097-z [50] Chiavazzo E, Morciano M, Viglino F, Fasano M, Asinari P. Passive solar high-yield seawater desalination by modular and low-cost distillation. Nat Sustain 1, 763–772 (2018). doi: 10.1038/s41893-018-0186-x [51] Alabastri A, Dongare PD, Neumann O, Metz J, Adebiyi I et al. Resonant energy transfer enhances solar thermal desalination. Energy Environ Sci 13, 968–976 (2020). doi: 10.1039/C9EE03256H -

Supplementary Information

Supplementary information for Janus aramid nanofiber aerogel incorporating plasmonic nanoparticles for high-efficiency interfacial solar steam generation

Supplementary video

-

Access History

Article Metrics

-

Figure 1.

The fabrication process of JANA for interfacial steam generation. (a) Photograph of commercial Kevlar threads. (b, c) Photograph and schematic illustration of aramid microfiber suspension and aramid nanofiber sol, respectively. (d) Photograph of aramid gel, whose top surface is sprayed with Au nanoparticle suspension. (e) Photograph of JANA and schematic illustrations depicting the microscopic morphology of the upside PANA and the downside ANA, respectively. (f) Schematic illustration of the steam generation process using JANA.

-

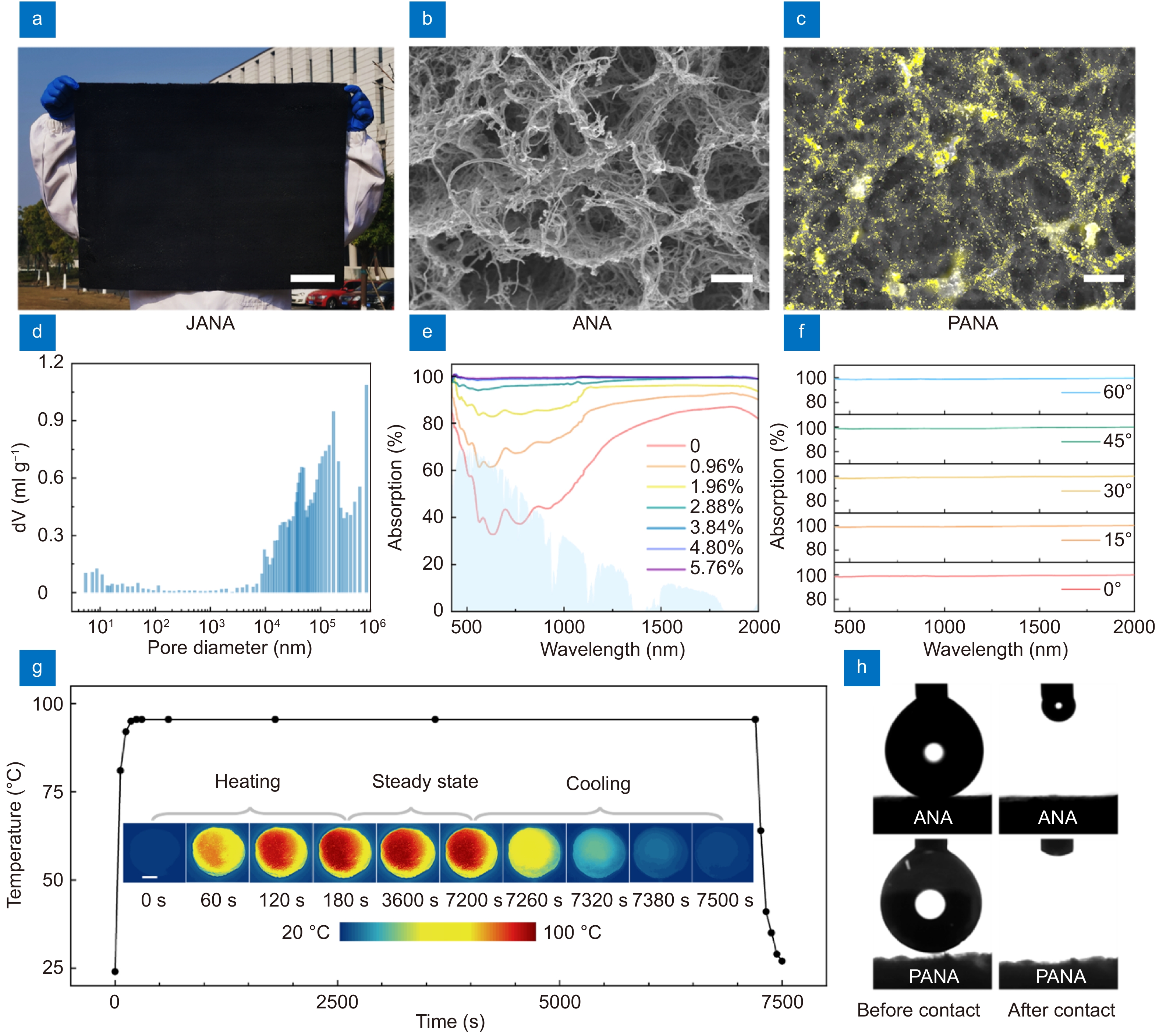

Figure 2.

Characterizations for morphology, optical absorption, photothermal responses and wettability. (a) Photograph of a large-area JANA cloth with the size of 60 cm × 45 cm. The scale bar stands for 10 cm. (b) SEM images of ANA. The scale bar stands for 1 μm. (c) SEM images of PANA, in which Au nanoparticles are highlighted using yellow fake color. The scale bar stands for 1 μm. (d) Correlation between the differential pore volume and the pore diameter in 1 gram of JANA measured using mercury intrusion method. (e) Absorption spectra of JANA samples with different weight fractions of Au nanoparticles. The blue area represents normalized power of solar irradiating power. (f) Absorption spectra of JANA under sources with different incident angles. (g) Correlation between the temperature variation of JANA and time using switched illumination by a solar simulator with 1-sun output power. Insets are IR images of the JANA at different moments during the photothermal test. (h) Photographs of an ANA and a PANA approaching to a water droplet, respectively.

-

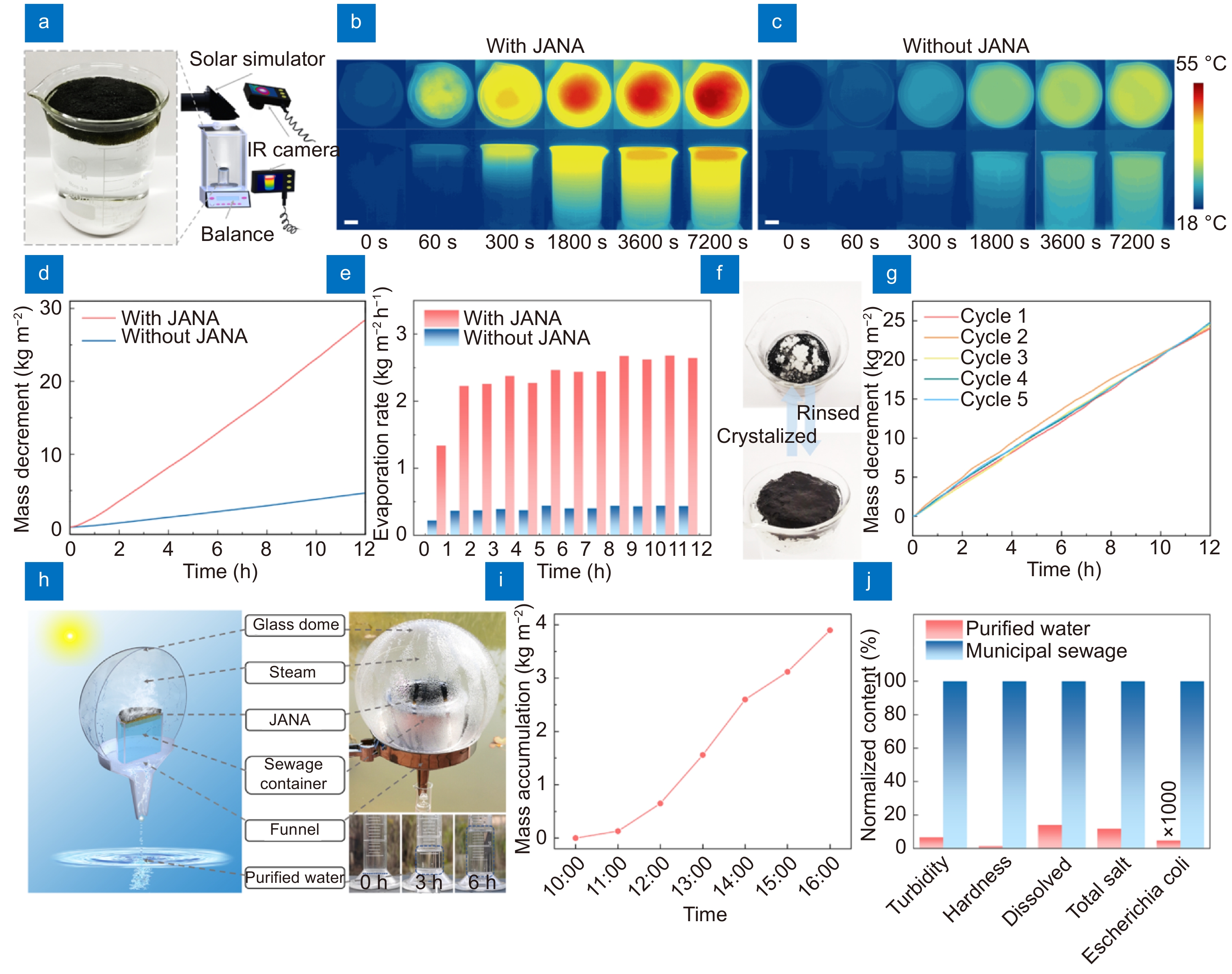

Figure 3.

Performances of steam generation using JANA. (a) (left) Photograph of the tested sample where JANA floats on a beaker of water. (right) Schematic illustration of the photo-thermo-gravimetry setup to record the real-time temperature and the mass change during the steam generation process. (b, c) (up) Top- and (down) side-view IR images of the beaker during steam generation process with and without the JANA, respectively. (d, e) Mass decrements and evaporation rates of water during the steam generation process with and without JANA, respectively. (f) Photographs of the (up) crystallized and (down) rinsed PANA in saturated NaCl solution, respectively. (g) Mass decrements of saturated NaCl solution during 5 cycles of steam generation processes using a same piece of JANA. (h) Schematic illustration and photograph of a home-made purification setup performing realistic ISSG. Right bottom insets show the accumulation of purified water at 0 h, 3 h, and 6 h, respectively. (i) Correlation between purified water accumulation and time. (j) Normalized contents of water quality indices in purified water and municipal sewage.

-

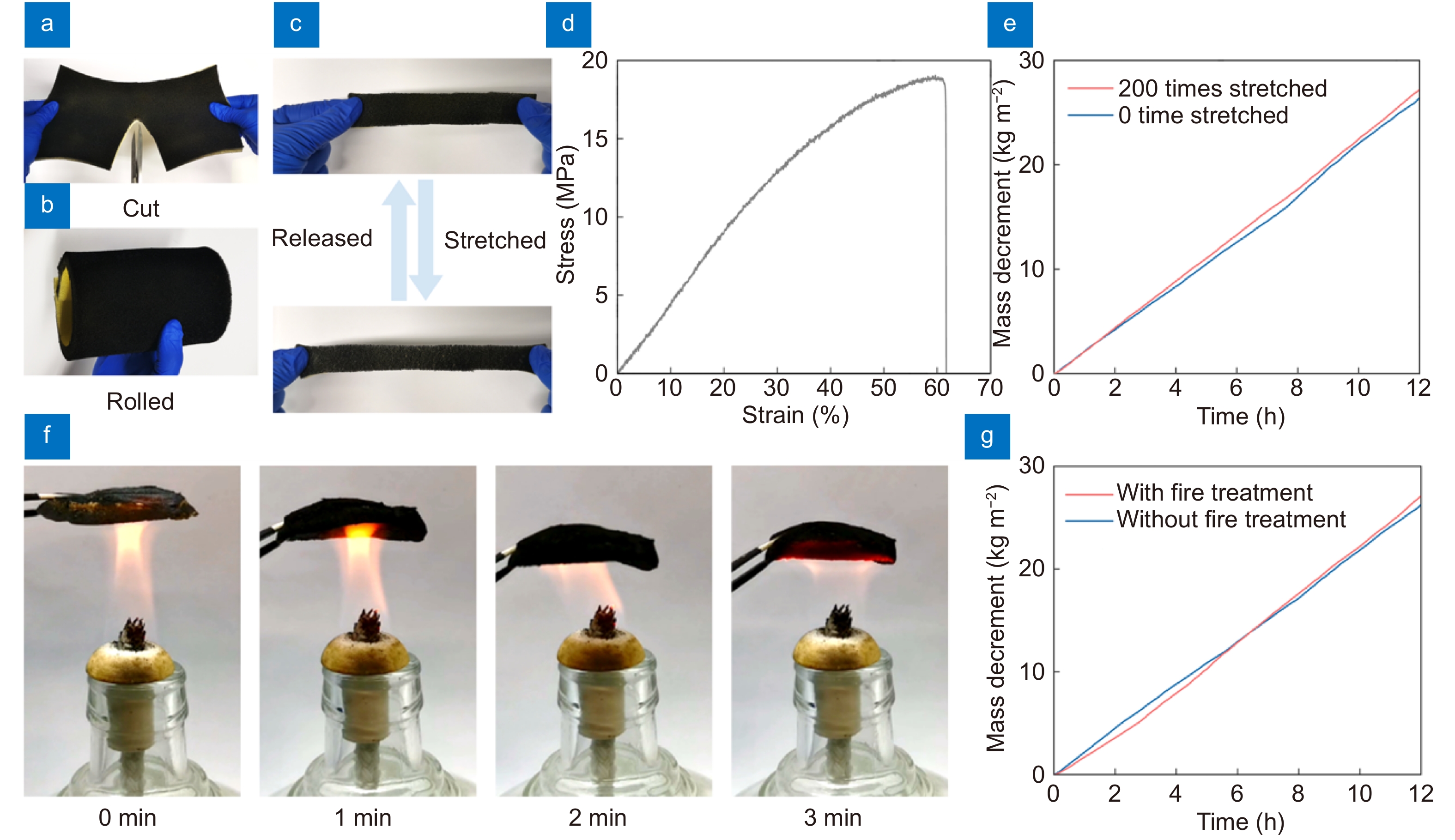

Figure 4.

Mechanical and fireproof properties of JANA. (a), (b) and (c) Photographs of JANA pieces which are cut off, rolled up, and elastically stretched, respectively. (d) Tensile stress of JANA. (e) Mass decrements of steam generation processes, in which the JANA is 0 time and 200 times repeatedly stretched, respectively. (f) Photographs of JANA under fire treatments for 0 min, 1 min, 2 min, and 3 min. (g) Mass decrements of steam generation processes, in which the JANA is without and with fire treatment, respectively.

E-mail Alert

E-mail Alert RSS

RSS

DownLoad:

DownLoad: