| Citation: | Wang DW, Han HL, Sa B, Li KL, Yan JJ et al. A review and a statistical analysis of porosity in metals additively manufactured by laser powder bed fusion. Opto-Electron Adv 5, 210058 (2022). doi: 10.29026/oea.2022.210058 |

A review and a statistical analysis of porosity in metals additively manufactured by laser powder bed fusion

-

Abstract

Additive manufacturing (AM), or 3D printing, is an emerging technology that “adds” materials up and constructs products through a layer-by-layer procedure. Laser powder bed fusion (LPBF) is a powder-bed-based AM technology that can fabricate a large variety of metallic materials with excellent quality and accuracy. However, various defects such as porosity, cracks, and incursions can be generated during the printing process. As the most universal and a near-inevitable defect, porosity plays a substantial role in determining the mechanical performance of as-printed products. This work presents a comprehensive review of literatures that focused on the porosity in LPBF printed metals. The formation mechanisms, evaluation methods, effects on mechanical performance with corresponding models, and controlling methods of porosity have been illustrated and discussed in-depth. Achievements in four representative metals, namely Ti−6Al−4V, 316L, Inconel 718, and AlSi10Mg, have been critically reviewed with a statistical analysis on the correlation between porosity fraction and tensile properties. Ductility has been determined as the most sensitive property to porosity among several key tensile properties. This review also provides potential directions and opportunities to address the current porosity-related challenges. -

-

References

[1] Gibson I, Rosen DW, Stucker B. Additive Manufacturing Technologies (Springer, Berlin, 2015). [2] Calignano F, Manfredi D, Ambrosio EP, Biamino S, Lombardi M et al. Overview on additive manufacturing technologies. Proc IEEE 105, 593–612 (2017). doi: 10.1109/JPROC.2016.2625098 [3] Lu BH, Lan HB, Liu HZ. Additive manufacturing frontier: 3D printing electronics. Opto-Electron Adv 1, 170004 (2018). [4] Brighenti R, Cosma MP, Marsavina L, Spagnoli A, Terzano M. Laser-based additively manufactured polymers: a review on processes and mechanical models. J Mater Sci 56, 961–998 (2021). doi: 10.1007/s10853-020-05254-6 [5] Zhou YH, Li WP, Wang DW, Zhang L, Ohara K et al. Selective laser melting enabled additive manufacturing of Ti–22Al–25Nb intermetallic: excellent combination of strength and ductility, and unique microstructural features associated. Acta Mater 173, 117–129 (2019). doi: 10.1016/j.actamat.2019.05.008 [6] Hu YB, Cong WL. A review on laser deposition-additive manufacturing of ceramics and ceramic reinforced metal matrix composites. Ceram Int 44, 20599–20612 (2018). doi: 10.1016/j.ceramint.2018.08.083 [7] Chueh YH, Zhang XJ, Wei C, Sun Z, Li L. Additive manufacturing of polymer-metal/ceramic functionally graded composite components via multiple material laser powder bed fusion. J Manuf Sci Eng 142, 051003 (2020). doi: 10.1115/1.4046594 [8] Lewandowski JJ, Seifi M. Metal additive manufacturing: a review of mechanical properties. Annu Rev Mater Res 46, 151–186 (2016). doi: 10.1146/annurev-matsci-070115-032024 [9] ISO/ASTM52900–15 Standard terminology for additive manufacturing – general principles – terminology. ASTM International,doi: 10.1520/ISOASTM52900-15 (2015). [10] Xie WD, Mu XX, Guo YX, et al. Research progress of additive manufacturing of high-performance polymers and the applications. Opto-Electron Eng 48, 210137 (2021). doi: 10.12086/oee.2021.210137 [11] Gebhardt A. Understanding Additive Manufacturing. Gebhardt A, ed. Understanding Additive Manufacturing, edn, (Hanser, Munich, Germany, 2011); https://doi.org/10.3139/9783446431621.fm. [12] Kang JW, Shangguan HL, Deng CY, Hu YY, Yi JH et al. Additive manufacturing-driven mold design for castings. Addit Manuf 22, 472–478 (2018). [13] Hirt L, Reiser A, Spolenak R, Zambelli T. Additive manufacturing of metal structures at the micrometer scale. Adv Mater 29, 1604211 (2017). doi: 10.1002/adma.201604211 [14] Herzog D, Seyda V, Wycisk E, Emmelmann C. Additive manufacturing of metals. Acta Mater 117, 371–392 (2016). doi: 10.1016/j.actamat.2016.07.019 [15] DebRoy T, Wei HL, Zuback JS, Mukherjee T, Elmer JW et al. Additive manufacturing of metallic components – Process, structure and properties. Prog Mater Sci 92, 112–224 (2018). doi: 10.1016/j.pmatsci.2017.10.001 [16] DebRoy T, Mukherjee T, Milewski JO, Elmer JW, Ribic B et al. Scientific, technological and economic issues in metal printing and their solutions. Nat Mater 18, 1026–1032 (2019). doi: 10.1038/s41563-019-0408-2 [17] Zhao XY, Deng WW. Printing photovoltaics by electrospray. Opto-Electron Adv 3, 190038 (2020). doi: 10.29026/oea.2020.190038 [18] Haghdadi N, Laleh M, Moyle M, Primig S. Additive manufacturing of steels: a review of achievements and challenges. J Mater Sci 56, 64–107 (2021). doi: 10.1007/s10853-020-05109-0 [19] Cunningham R, Zhao C, Parab N, Kantzos C, Pauza J et al. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging. Science 363, 849–852 (2019). doi: 10.1126/science.aav4687 [20] Opatová K, Zetková I, Kučerová L. Relationship between the size and inner structure of particles of virgin and re-used MS1 maraging steel powder for additive manufacturing. Materials 13, 956 (2020). doi: 10.3390/ma13040956 [21] Bartlett JL, Li XD. An overview of residual stresses in metal powder bed fusion. Addit Manuf 27, 131–149 (2019). [22] Kruth JP, Levy G, Klocke F, Childs THC. Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann 56, 730–759 (2007). doi: 10.1016/j.cirp.2007.10.004 [23] Yap CY, Chua CK, Dong ZL, Liu ZH, Zhang DQ et al. Review of selective laser melting: materials and applications. Appl Phys Rev 2, 041101 (2015). doi: 10.1063/1.4935926 [24] Tan JH, Wong WLE, Dalgarno KW. An overview of powder granulometry on feedstock and part performance in the selective laser melting process. Addit Manuf 18, 228–255 (2017). [25] Dong YP, Tang JC, Wang DW, Wang N, He ZD et al. Additive manufacturing of pure Ti with superior mechanical performance, low cost, and biocompatibility for potential replacement of Ti-6Al-4V. Mater Design 196, 109142 (2020). doi: 10.1016/j.matdes.2020.109142 [26] Wang JC, Liu YJ, Qin P, Liang SX, Sercombe TB et al. Selective laser melting of Ti–35Nb composite from elemental powder mixture: microstructure, mechanical behavior and corrosion behavior. Mater Sci Eng:A 760, 214–224 (2019). doi: 10.1016/j.msea.2019.06.001 [27] Khairallah SA, Anderson AT, Rubenchik A, King WE. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater 108, 36–45 (2016). doi: 10.1016/j.actamat.2016.02.014 [28] Khairallah SA, Martin AA, Lee JRI, Guss G, Calta NP et al. Controlling interdependent meso-nanosecond dynamics and defect generation in metal 3D printing. Science 368, 660–665 (2020). doi: 10.1126/science.aay7830 [29] Zhao C, Parab ND, Li XX, Fezzaa K, Tan WD et al. Critical instability at moving keyhole tip generates porosity in laser melting. Science 370, 1080–1086 (2020). doi: 10.1126/science.abd1587 [30] Zhang B, Li YT, Bai Q. Defect formation mechanisms in selective laser melting: a review. Chin J Mech Eng 30, 515–527 (2017). doi: 10.1007/s10033-017-0121-5 [31] Taheri H, Shoaib MRBM, Koester LW, Bigelow TA, Collins PC et al. Powder-based additive manufacturing - a review of types of defects, generation mechanisms, detection, property evaluation and metrology. Int J Addit Subtract Mater Manuf 1, 172–209 (2017). [32] Gu DD, Hagedorn YC, Meiners W, Meng GB, Batista RJS et al. Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Mater 60, 3849–3860 (2012). doi: 10.1016/j.actamat.2012.04.006 [33] Bidare P, Bitharas I, Ward RM, Attallah MM, Moore AJ. Fluid and particle dynamics in laser powder bed fusion. Acta Mater 142, 107–120 (2018). doi: 10.1016/j.actamat.2017.09.051 [34] Ye JC, Khairallah SA, Rubenchik AM, Crumb MF, Guss G et al. Energy coupling mechanisms and scaling behavior associated with laser powder bed fusion additive manufacturing. Adv Eng Mater 21, 1900185 (2019). doi: 10.1002/adem.201900185 [35] Tenbrock C, Kelliger T, Praetzsch N, Ronge M, Jauer L et al. Effect of laser-plume interaction on part quality in multi-scanner Laser Powder Bed Fusion. Addit Manuf 38, 101810 (2021). [36] Xie XZ, Zhou CX, Wei X, Hu W, Ren QL. Laser machining of transparent brittle materials: from machining strategies to applications. Opto-Electron Adv 2, 180017 (2019). [37] Wang DW, Zhou YH, Shen J, Liu Y, Li DF et al. Selective laser melting under the reactive atmosphere: a convenient and efficient approach to fabricate ultrahigh strength commercially pure titanium without sacrificing ductility. Mater Sci Eng:A 762, 138078 (2019). doi: 10.1016/j.msea.2019.138078 [38] Sanaei N, Fatemi A. Defects in additive manufactured metals and their effect on fatigue performance: a state-of-the-art review. Prog Mater Sci 117, 100724 (2021). doi: 10.1016/j.pmatsci.2020.100724 [39] Leung CLA, Marussi S, Atwood RC, Towrie M, Withers PJ et al. In situ X-ray imaging of defect and molten pool dynamics in laser additive manufacturing. Nat Commun 9, 1355 (2018). [40] Du Plessis A, Yadroitsava I, Yadroitsev I. Effects of defects on mechanical properties in metal additive manufacturing: a review focusing on X-ray tomography insights. Mater Design 187, 108385 (2020). doi: 10.1016/j.matdes.2019.108385 [41] Pineau A, Benzerga AA, Pardoen T. Failure of metals I: brittle and ductile fracture. Acta Mater 107, 424–483 (2016). doi: 10.1016/j.actamat.2015.12.034 [42] Ng GKL, Jarfors AEW, Bi G, Zheng HY. Porosity formation and gas bubble retention in laser metal deposition. Appl Phys A 97, 641–649 (2009). doi: 10.1007/s00339-009-5266-3 [43] Kasperovich G, Haubrich J, Gussone J, Requena G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater Design 105, 160–170 (2016). doi: 10.1016/j.matdes.2016.05.070 [44] Zhou X, Wang DZ, Liu XH, Zhang DD, Qu SL et al. 3D-imaging of selective laser melting defects in a Co–Cr–Mo alloy by synchrotron radiation micro-CT. Acta Mater 98, 1–16 (2015). doi: 10.1016/j.actamat.2015.07.014 [45] Leuders S, Thöne M, Riemer A, Niendorf T, Tröster T et al. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: fatigue resistance and crack growth performance. Int J Fatigue 48, 300–307 (2013). doi: 10.1016/j.ijfatigue.2012.11.011 [46] Zhao B, Gain AK, Ding WF, Zhang LC, Li XY et al. A review on metallic porous materials: pore formation, mechanical properties, and their applications. Int J Adv Manuf Technol 95, 2641–2659 (2018). doi: 10.1007/s00170-017-1415-6 [47] Tammas-Williams S, Withers PJ, Todd I, Prangnell PB. Porosity regrowth during heat treatment of hot isostatically pressed additively manufactured titanium components. Scr Mater 122, 72–76 (2016). [48] Girelli L, Tocci M, Gelfi M, Pola A. Study of heat treatment parameters for additively manufactured AlSi10Mg in comparison with corresponding cast alloy. Mater Sci Eng:A 739, 317–328 (2019). doi: 10.1016/j.msea.2018.10.026 [49] Barua S, Liou F, Newkirk J, Sparks T. Vision-based defect detection in laser metal deposition process. Rapid Prototyping J 20, 77–85 (2014). doi: 10.1108/RPJ-04-2012-0036 [50] Hojjatzadeh SMH, Parab ND, Yan WT, Guo QL, Xiong LH et al. Pore elimination mechanisms during 3D printing of metals. Nat Commun 10, 3088 (2019). doi: 10.1038/s41467-019-10973-9 [51] King WE, Barth HD, Castillo VM, Gallegos GF, Gibbs JW et al. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J Mater Process Technol 214, 2915–2925 (2014). doi: 10.1016/j.jmatprotec.2014.06.005 [52] Ge WJ, Fuh JYH, Na SJ. Numerical modelling of keyhole formation in selective laser melting of Ti6Al4V. J Manuf Process 62, 646–654 (2021). doi: 10.1016/j.jmapro.2021.01.005 [53] Wang L, Zhang YM, Yan WT. Evaporation model for keyhole dynamics during additive manufacturing of metal. Phys Rev Appl 14, 064039 (2020). doi: 10.1103/PhysRevApplied.14.064039 [54] Zhao C, Guo QL, Li XX, Parab N, Fezzaa K et al. Bulk-explosion-induced metal spattering during laser processing. Phys Rev X 9, 021052 (2019). [55] Anisimov SI, Khokhlov VA. Instabilities in Laser-Matter Interaction. (CRC Press, Boca Raton, 1995). [56] Sankin GN, Simmons WN, Zhu SL, Zhong P. Shock wave interaction with laser-generated single bubbles. Phys Rev Lett 95, 034501 (2005). doi: 10.1103/PhysRevLett.95.034501 [57] Tang M, Pistorius PC. Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting. Int J Fatigue 94, 192–201 (2017). doi: 10.1016/j.ijfatigue.2016.06.002 [58] Weingarten C, Buchbinder D, Pirch N, Meiners W, Wissenbach K et al. Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg. J Mater Process Technol 221, 112–120 (2015). doi: 10.1016/j.jmatprotec.2015.02.013 [59] Zeng GH, Song T, Dai YH, Tang HP, Yan M. 3D printed breathable mould steel: small micrometer-sized, interconnected pores by creatively introducing foaming agent to additive manufacturing. Mater Design 169, 107693 (2019). doi: 10.1016/j.matdes.2019.107693 [60] Chen G, Zhao SY, Tan P, Wang J, Xiang CS et al. A comparative study of Ti-6Al-4V powders for additive manufacturing by gas atomization, plasma rotating electrode process and plasma atomization. Powder Technol 333, 38–46 (2018). doi: 10.1016/j.powtec.2018.04.013 [61] Chen G, Zhou Q, Zhao SY, Yin JO, Tan P et al. A pore morphological study of gas-atomized Ti-6Al-4V powders by scanning electron microscopy and synchrotron X-ray computed tomography. Powder Technol 330, 425–430 (2018). doi: 10.1016/j.powtec.2018.02.053 [62] Ternovoi YF, Tsipunov AG, Kuratchenko SB, Kuimova OM, Kondakova KV. Pore formation in atomized powders. Sov Powder Metall Met Ceram 24, 10–13 (1985). doi: 10.1007/BF00792199 [63] Tammas-Williams S, Zhao H, Léonard F, Derguti F, Todd I et al. XCT analysis of the influence of melt strategies on defect population in Ti–6Al–4V components manufactured by Selective Electron Beam Melting. Mater Characteriz 102, 47–61 (2015). doi: 10.1016/j.matchar.2015.02.008 [64] Wu ZH, Basu D, Meyer JLL, Larson E, Kuo R et al. Study of powder gas entrapment and its effects on porosity in 17-4 PH stainless steel parts fabricated in laser powder bed fusion. JOM 73, 177–188 (2021). doi: 10.1007/s11837-020-04491-z [65] Li S, Hassanin H, Attallah MM, Adkins NJE, Essa K. The development of TiNi-based negative Poisson's ratio structure using selective laser melting. Acta Mater 105, 75–83 (2016). doi: 10.1016/j.actamat.2015.12.017 [66] Cunningham R, Nicolas A, Madsen J, Fodran E, Anagnostou E et al. Analyzing the effects of powder and post-processing on porosity and properties of electron beam melted Ti-6Al-4V. Mater Res Lett 5, 516–525 (2017). doi: 10.1080/21663831.2017.1340911 [67] Braun J, Kaserer L, Stajkovic J, Leitz KH, Tabernig B et al. Molybdenum and tungsten manufactured by selective laser melting: analysis of defect structure and solidification mechanisms. Int J Refract Met Hard Mater 84, 104999 (2019). doi: 10.1016/j.ijrmhm.2019.104999 [68] Polozov I, Sufiiarov V, Kantyukov A, Popovich A. Selective Laser Melting of Ti2AlNb-based intermetallic alloy using elemental powders: effect of process parameters and post-treatment on microstructure, composition, and properties. Intermetallics 112, 106554 (2019). doi: 10.1016/j.intermet.2019.106554 [69] Tang M, Pistorius PC, Beuth JL. Prediction of lack-of-fusion porosity for powder bed fusion. Addit Manuf 14, 39–48 (2017). [70] Chlebus E, Kuźnicka B, Kurzynowski T, Dybała B. Microstructure and mechanical behaviour of Ti―6Al―7Nb alloy produced by selective laser melting. Mater Characteriz 62, 488–495 (2011). doi: 10.1016/j.matchar.2011.03.006 [71] Attar H, Löber L, Funk A, Calin M, Zhang LC et al. Mechanical behavior of porous commercially pure Ti and Ti–TiB composite materials manufactured by selective laser melting. Mater Sci Eng:A 625, 350–356 (2015). doi: 10.1016/j.msea.2014.12.036 [72] Hou YH, Liu B, Liu Y, Zhou YH, Song TT et al. Ultra-low cost Ti powder for selective laser melting additive manufacturing and superior mechanical properties associated. Opto-Electron Adv 2, 180028 (2019). [73] Honarvar F, Varvani-Farahani A. A review of ultrasonic testing applications in additive manufacturing: defect evaluation, material characterization, and process control. Ultrasonics 108, 106227 (2020). doi: 10.1016/j.ultras.2020.106227 [74] Waller JM, Parker BH, Hodges KL, Burke ER, Walker JL et al. Nondestructive evaluation of additive manufacturing. National Aeronautics and Space Administration, (2014). [75] Masuo H, Tanaka Y, Morokoshi S, Yagura H, Uchida T et al. Effects of defects, surface roughness and HIP on fatigue strength of Ti-6Al-4V manufactured by additive manufacturing. Proced Struct Integrity 7, 19–26 (2017). doi: 10.1016/j.prostr.2017.11.055 [76] Wits WW, Carmignato S, Zanini F, Vaneker THJ. Porosity testing methods for the quality assessment of selective laser melted parts. CIRP Ann 65, 201–204 (2016). doi: 10.1016/j.cirp.2016.04.054 [77] Rafi HK, Karthik NV, Gong HJ, Starr TL, Stucker BE. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting. J Mater Eng Perform 22, 3872–3883 (2013). doi: 10.1007/s11665-013-0658-0 [78] Slotwinski JA, Garboczi EJ. Porosity of additive manufacturing parts for process monitoring. AIP Conf Proc 1581, 1197–1204 (2014). [79] Monchiet V, Bonnet G. A gurson-type model accounting for void size effects. Int J Solids Struct 50, 320–327 (2013). doi: 10.1016/j.ijsolstr.2012.09.005 [80] Becker R. The effect of porosity distribution on ductile failure. J Mech Phys Solids 35, 577–599 (1987). doi: 10.1016/0022-5096(87)90018-4 [81] Romano S, Abel A, Gumpinger J, Brandão AD, Beretta S. Quality control of AlSi10Mg produced by SLM: metallography versus CT scans for critical defect size assessment. Addit Manuf 28, 394–405 (2019). [82] Romano S, Brandão A, Gumpinger J, Gschweitl M, Beretta S. Qualification of AM parts: extreme value statistics applied to tomographic measurements. Mater Design 131, 32–48 (2017). doi: 10.1016/j.matdes.2017.05.091 [83] Murakami Y. Effects of small defects and nonmetallic inclusions on the fatigue strength of metals. JSME Int J Ser I, Solid Mech Strength Mater 32, 167–180 (1989). doi: 10.1299/jsmea1988.32.2_167 [84] Sanaei N, Fatemi A, Phan N. Defect characteristics and analysis of their variability in metal L-PBF additive manufacturing. Mater Design 182, 108091 (2019). doi: 10.1016/j.matdes.2019.108091 [85] Romano S, Brückner-Foit A, Brandão A, Gumpinger J, Ghidini T et al. Fatigue properties of AlSi10Mg obtained by additive manufacturing: defect-based modelling and prediction of fatigue strength. Eng Fract Mech 187, 165–189 (2018). doi: 10.1016/j.engfracmech.2017.11.002 [86] Murakami Y, Beretta S. Small defects and inhomogeneities in fatigue strength: experiments, models and statistical implications. Extremes 2, 123–147 (1999). doi: 10.1023/A:1009976418553 [87] Pineau A, McDowell DL, Busso EP, Antolovich SD. Failure of metals II: fatigue. Acta Mater 107, 484–507 (2016). doi: 10.1016/j.actamat.2015.05.050 [88] Murakami Y. Inclusion rating by statistics of extreme values and its application to fatigue strength prediction and quality control of materials. J Res Natl Inst Stand Technol 99, 345–351 (1994). doi: 10.6028/jres.099.032 [89] Dowling NE, Katakam S, Narayanasamy R. Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture, and Fatigue (Pearson Education Limited, London, 2012). [90] Kabir MR, Richter H. Modeling of processing-induced pore morphology in an additively-manufactured Ti-6Al-4V alloy. Materials 10, 145 (2017). doi: 10.3390/ma10020145 [91] Mbiakop A, Constantinescu A, Danas K. An analytical model for porous single crystals with ellipsoidal voids. J Mech Phys Solids 84, 436–467 (2015). doi: 10.1016/j.jmps.2015.07.011 [92] Madou K, Leblond JB, Morin L. Numerical studies of porous ductile materials containing arbitrary ellipsoidal voids – II: Evolution of the length and orientation of the void axes. Eur J Mech - A/Solid 42, 490–507 (2013). doi: 10.1016/j.euromechsol.2013.06.005 [93] Komori K. Improvement of an ellipsoidal void model for simulating ductile fracture behavior. Key Eng Mater 577–578, 93–96 (2013). [94] Komori K. An ellipsoidal void model for simulating ductile fracture behavior. Mech Mater 60, 36–54 (2013). doi: 10.1016/j.mechmat.2013.01.002 [95] Hidetaka K. What did archimedes find at “Eureka” moment?. Paipetis SA, Ceccarelli M, eds. The Genius of Archimedes -- 23 Centuries of Influence on Mathematics, Science and Engineering, 265–276 (Springer, Dordrecht, 2010). [96] Spierings AB, Schneider M, Eggenberger R. Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyping J 17, 380–386 (2011). doi: 10.1108/13552541111156504 [97] Kasperovich G, Hausmann J. Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting. J Mater Process Technol 220, 202–214 (2015). doi: 10.1016/j.jmatprotec.2015.01.025 [98] Chen P, Li S, Zhou YH, Yan M, Attallah MM. Fabricating CoCrFeMnNi high entropy alloy via selective laser melting in-situ alloying. J Mater Sci Technol 43, 40–43 (2020). doi: 10.1016/j.jmst.2020.01.002 [99] Taylor RP, McClain ST, Berry JT. Uncertainty analysis of metal-casting porosity measurements using Archimedes' principle. Int J Cast Met Res 11, 247–257 (1999). doi: 10.1080/13640461.1999.11819281 [100] Kak AC, Slaney M, Wang G. Principles of computerized tomographic imaging. Med Phys 29, 107 (2002). [101] Cunningham R, Narra SP, Montgomery C, Beuth J, Rollett AD. Synchrotron-based X-ray microtomography characterization of the effect of processing variables on porosity formation in laser power-bed additive manufacturing of Ti-6Al-4V. JOM 69, 479–484 (2017). doi: 10.1007/s11837-016-2234-1 [102] Kantzos CA, Cunningham RW, Tari V, Rollett AD. Characterization of metal additive manufacturing surfaces using synchrotron X-ray CT and micromechanical modeling. Comput Mech 61, 575–580 (2018). doi: 10.1007/s00466-017-1531-z [103] Abd Halim S, Abd Halim MS, Hadi NA. Surface Reconstruction from Computed Tomography (CT) Image of Human Head with the Effect of Noise. AIP Conf Proc 2013, 020017 (2018). [104] Ziółkowski G, Chlebus E, Szymczyk P, Kurzac J. Application of X-ray CT method for discontinuity and porosity detection in 316L stainless steel parts produced with SLM technology. Arch Civ Mech Eng 14, 608–614 (2014). doi: 10.1016/j.acme.2014.02.003 [105] Gong H, Rafi K, Starr T, Stucker B. c. In Proceedings of the 24th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference 12–14 (2013). [106] Vanderesse N, Ky I, González FQ, Nuño N, Bocher P. Image analysis characterization of periodic porous materials produced by additive manufacturing. Mater Design 92, 767–778 (2016). doi: 10.1016/j.matdes.2015.12.062 [107] Xia MJ, Gu DD, Yu GQ, Dai DH, Chen HY et al. Porosity evolution and its thermodynamic mechanism of randomly packed powder-bed during selective laser melting of Inconel 718 alloy. Int J Mach Tools Manu 116, 96–106 (2017). doi: 10.1016/j.ijmachtools.2017.01.005 [108] Attar H, Ehtemam-Haghighi S, Kent D, Wu XH, Dargusch MS. Comparative study of commercially pure titanium produced by laser engineered net shaping, selective laser melting and casting processes. Mater Sci Eng:A 705, 385–393 (2017). doi: 10.1016/j.msea.2017.08.103 [109] Cheeke JDN. Fundamentals and Applications of Ultrasonic Waves (CRC Press, Boca Raton, 2010). [110] Shull PJ. Nondestructive Evaluation: Theory, Techniques, and Applications (Marcel Dekker, New York, 2002). [111] Fathi-Haftshejani P, Honarvar F. Nondestructive evaluation of clad rods by inversion of acoustic scattering data. J Nondestruct Eval 38, 67 (2019). doi: 10.1007/s10921-019-0605-6 [112] Everton SK, Dickens P, Tuck C, Dutton B. Identification of sub-surface defects in parts produced by additive manufacturing, using laser generated ultrasound. Additive Manufacturing and 3D Printing Research Group, University of Nottingham, (2016). [113] Slotwinski JA, Garboczi EJ, Hebenstreit KM. Porosity measurements and analysis for metal additive manufacturing process control. J Res Natl Inst Stand Technol 119, 494–528 (2014). doi: 10.6028/jres.119.019 [114] Cerniglia D, Scafidi M, Pantano A, Rudlin J. Inspection of additive-manufactured layered components. Ultrasonics 62, 292–298 (2015). doi: 10.1016/j.ultras.2015.06.001 [115] Nadimpalli VK, Yang L, Nagy PB. In-situ interfacial quality assessment of Ultrasonic Additive Manufacturing components using ultrasonic NDE. NDT E Int 93, 117–130 (2018). [116] Javadi Y, Mohseni E, MacLeod CN, Lines D, Vasilev M et al. Continuous monitoring of an intentionally-manufactured crack using an automated welding and in-process inspection system. Mater Design 191, 108655 (2020). doi: 10.1016/j.matdes.2020.108655 [117] Wang XH, Li WT, Li Y, Zhou ZG, Zhang JJ et al. Phased array ultrasonic testing of micro-flaws in additive manufactured titanium block. Mater Res Express 7, 016572 (2020). doi: 10.1088/2053-1591/ab6929 [118] Mahmoudi M, Elwany A, Yadollahi A, Thompson SM, Bian LK et al. Mechanical properties and microstructural characterization of selective laser melted 17-4 PH stainless steel. Rapid Prototyping J 23, 280–294 (2017). doi: 10.1108/RPJ-12-2015-0192 [119] Vilardell AM, Fredriksson G, Yadroitsev I, Krakhmalev P. Fracture mechanisms in the as-built and stress-relieved laser powder bed fusion Ti6Al4V ELI alloy. Opt Laser Technol 109, 608–615 (2019). doi: 10.1016/j.optlastec.2018.08.042 [120] Su XM. Toward an understanding of local variability of fatigue strength with microstructures. Int J Fatigue 30, 1007–1015 (2008). doi: 10.1016/j.ijfatigue.2007.08.016 [121] Geetha M, Singh AK, Asokamani R, Gogia AK. Ti based biomaterials, the ultimate choice for orthopaedic implants – A review. Prog Mater Sci 54, 397–425 (2009). doi: 10.1016/j.pmatsci.2008.06.004 [122] Luo JP, Huang YJ, Xu JY, Sun JF, Dargusch MS et al. Additively manufactured biomedical Ti-Nb-Ta-Zr lattices with tunable Young's modulus: mechanical property, biocompatibility, and proteomics analysis. Mater Sci Eng:C 114, 110903 (2020). doi: 10.1016/j.msec.2020.110903 [123] Gong HJ, Rafi K, Gu HF, Ram GDJ, Starr T et al. Influence of defects on mechanical properties of Ti–6Al–4 V components produced by selective laser melting and electron beam melting. Mater Design 86, 545–554 (2015). doi: 10.1016/j.matdes.2015.07.147 [124] Waddell M, Walker K, Bandyopadhyay R, Kapoor K, Mallory A et al. Small fatigue crack growth behavior of Ti-6Al-4V produced via selective laser melting: in situ characterization of a 3D crack tip interactions with defects. Int J Fatigue 137, 105638 (2020). [125] Aqida SN, Ghazali MI, Hashim J. Effect of porosity on mechanical properties of metal matrix composite: an overview. Jurnal Teknologi 40, 17–32 (2004). [126] Hardin RA, Beckermann C. Effect of porosity on the stiffness of cast steel. Metall Mater Trans A 38, 2992–3006 (2007). doi: 10.1007/s11661-007-9390-4 [127] Schijve J. Stress concentration at notches. Schijve J, ed. Fatigue of Structures and Materials, 45–70 (Springer, Dordrecht, 2001). [128] Bert CW. Prediction of elastic moduli of solids with oriented porosity. J Mater Sci 20, 2220–2224 (1985). [129] Rossi RC. Prediction of the elastic moduli of composites. J Am Ceram Soc 51, 433–440 (1968). doi: 10.1111/j.1151-2916.1968.tb11914.x [130] Roberts AP, Garboczi EJ. Elastic properties of model porous ceramics. J Am Ceram Soc 83, 3041–3048 (2000). doi: 10.1111/j.1151-2916.2000.tb01680.x [131] Zhang EL, Wang B. On the compressive behaviour of sintered porous coppers with low to medium porosities—Part I: experimental study. Int J Mech Sci 47, 744–756 (2005). doi: 10.1016/j.ijmecsci.2004.12.011 [132] Gibson LJ, Ashby MF. Cellular Solids: Structure and Properties 2nd ed (Cambridge University Press, Cambridge, 1997). [133] Tekmen C, Ozdemir I, Cocen U, Onel K. The mechanical response of Al–Si–Mg/SiCp composite: influence of porosity. Mater Sci Eng:A 360, 365–371 (2003). doi: 10.1016/S0921-5093(03)00461-1 [134] Palchik V, Hatzor YH. The influence of porosity on tensile and compressive strength of porous chalks. Rock Mech Rock Eng 37, 331–341 (2004). doi: 10.1007/s00603-003-0020-1 [135] Lecarme L, Tekog̃lu C, Pardoen T. Void growth and coalescence in ductile solids with stage III and stage IV strain hardening. Int J Plast 27, 1203–1223 (2011). [136] Feng ZQ, Yang YQ, Chen YX, Huang B, Fu MS et al. In-situ TEM investigation of fracture process in an Al–Cu–Mg alloy. Mater Sci Eng:A 586, 259–266 (2013). doi: 10.1016/j.msea.2013.08.013 [137] Ragab AR. A model for ductile fracture based on internal necking of spheroidal voids. Acta Mater 52, 3997–4009 (2004). doi: 10.1016/j.actamat.2004.05.015 [138] Yadroitsev I, Krakhmalev P, Yadroitsava I, Du Plessis A. Qualification of Ti6Al4V ELI alloy produced by laser powder bed fusion for biomedical applications. JOM 70, 372–377 (2018). doi: 10.1007/s11837-017-2655-5 [139] Rollett AD, Kocks UF. A review of the stages of work hardening. Solid State Phenom 35–36, 1–18 (1993). [140] Susmel L, Taylor D. On the use of the theory of critical distances to predict static failures in ductile metallic materials containing different geometrical features. Eng Fract Mech 75, 4410–4421 (2008). doi: 10.1016/j.engfracmech.2008.04.018 [141] Voisin T, Calta NP, Khairallah SA, Forien JB, Balogh L et al. Defects-dictated tensile properties of selective laser melted Ti-6Al-4V. Mater Design 158, 113–126 (2018). [142] Benzerga AA, Besson J, Pineau A. Anisotropic ductile fracture: Part I: experiments. Acta Mater 52, 4623–4638 (2004). doi: 10.1016/j.actamat.2004.06.020 [143] Gurson AL. Continuum theory of ductile rupture by void nucleation and growth: Part I—yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99, 2–15 (1977). doi: 10.1115/1.3443401 [144] Tvergaard V. On localization in ductile materials containing spherical voids. Int J Fract 18, 237–252 (1982). doi: 10.1007/BF00015686 [145] Needleman A. A continuum model for void nucleation by inclusion debonding. J Appl Mech Sep 54, 525–531 (1987). doi: 10.1115/1.3173064 [146] Hao S, Brocks W. The Gurson-Tvergaard-Needleman-model for rate and temperature-dependent materials with isotropic and kinematic hardening. Comput Mech 20, 34–40 (1997). doi: 10.1007/s004660050213 [147] Haynes R. A study of the effect of porosity content on the ductility of sintered metals. Powder Metal 20, 17–20 (1977). doi: 10.1179/pom.1977.20.1.17 [148] Yadollahi A, Shamsaei N. Additive manufacturing of fatigue resistant materials: challenges and opportunities. Int J Fatigue 98, 14–31 (2017). doi: 10.1016/j.ijfatigue.2017.01.001 [149] Daniewicz SR, Shamsaei N. An introduction to the fatigue and fracture behavior of additive manufactured parts. Int J Fatigue 94, 167 (2017). doi: 10.1016/j.ijfatigue.2016.07.007 [150] Tammas-Williams S, Withers PJ, Todd I, Prangnell PB. The influence of porosity on fatigue crack initiation in additively manufactured titanium components. Sci Rep 7, 7308 (2017). doi: 10.1038/s41598-017-06504-5 [151] Biswal R, Zhang X, Syed AK, Awd M, Ding JL et al. Criticality of porosity defects on the fatigue performance of wire + arc additive manufactured titanium alloy. Int J Fatigue 122, 208–217 (2019). doi: 10.1016/j.ijfatigue.2019.01.017 [152] Liao D, Zhu SP, Correia JAFO, De Jesus AMP, Berto F. Recent advances on notch effects in metal fatigue: a review. Fatigue Fract Eng Mater Struct 43, 637–659 (2020). doi: 10.1111/ffe.13195 [153] Chastand V, Tezenas A, Cadoret Y, Quaegebeur P, Maia W et al. Fatigue characterization of Titanium Ti-6Al-4V samples produced by additive manufacturing. Proced Struct Inte 2, 3168–3176 (2016). [154] Taylor D. The theory of critical distances. Eng Fract Mech 75, 1696–1705 (2008). doi: 10.1016/j.engfracmech.2007.04.007 [155] Skallerud B, Iveland T, Härkegård G. Fatigue life assessment of aluminum alloys with casting defects. Eng Fract Mech 44, 857–874 (1993). doi: 10.1016/0013-7944(93)90108-5 [156] Sheridan L, Scott-Emuakpor OE, George T, Gockel JE. Relating porosity to fatigue failure in additively manufactured alloy 718. Mater Sci Eng:A 727, 170–176 (2018). doi: 10.1016/j.msea.2018.04.075 [157] Yamashita Y, Murakami T, Mihara R, Okada M, Murakami Y. Defect analysis and fatigue design basis for Ni-based superalloy 718 manufactured by selective laser melting. Int J Fatigue 117, 485–495 (2018). doi: 10.1016/j.ijfatigue.2018.08.002 [158] Prithivirajan V, Sangid MD. The role of defects and critical pore size analysis in the fatigue response of additively manufactured IN718 via crystal plasticity. Mater Design 150, 139–153 (2018). doi: 10.1016/j.matdes.2018.04.022 [159] Murakami Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions 2nd ed (Academic Press, London, 2019). [160] Susmel L. The theory of critical distances: a review of its applications in fatigue. Eng Fract Mech 75, 1706–1724 (2008). doi: 10.1016/j.engfracmech.2006.12.004 [161] Taylor D. Applications of the theory of critical distances in failure analysis. Eng Fail Anal 18, 543–549 (2011). doi: 10.1016/j.engfailanal.2010.07.002 [162] Newman JC, Piascik RS. Fatigue Crack Growth Thresholds, Endurance Limits, and Design (ASTM International, West Conshohocken, PA, 2000). [163] Witkin DB, Patel DN, Helvajian H, Steffeney L, Diaz A. Surface treatment of powder-bed fusion additive manufactured metals for improved fatigue life. J Mater Eng Perform 28, 681–692 (2019). doi: 10.1007/s11665-018-3732-9 [164] Fatemi A, Molaei R, Phan N. Multiaxial fatigue of additive manufactured metals. MATEC Web Conf 300, 01003 (2019). doi: 10.1051/matecconf/201930001003 [165] Ronneberg T, Davies CM, Hooper PA. Revealing relationships between porosity, microstructure and mechanical properties of laser powder bed fusion 316L stainless steel through heat treatment. Mater Design 189, 108481 (2020). doi: 10.1016/j.matdes.2020.108481 [166] Shipley H, McDonnell D, Culleton M, Coull R, Lupoi R et al. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: a review. Int J Mach Tools Manuf 128, 1–20 (2018). doi: 10.1016/j.ijmachtools.2018.01.003 [167] DebRoy T, Mukherjee T, Wei HL, Elmer JW, Milewski JO. Metallurgy, mechanistic models and machine learning in metal printing. Nat Rev Mater 6, 48–68 (2021). doi: 10.1038/s41578-020-00236-1 [168] Lütjering G, Williams JC. Titanium (Springer, Berlin Heidelberg, 2007). [169] Qian M, Xu W, Brandt M, Tang HP. Additive manufacturing and postprocessing of Ti-6Al-4V for superior mechanical properties. MRS Bull 41, 775–784 (2016). doi: 10.1557/mrs.2016.215 [170] Liu SY, Shin YC. Additive manufacturing of Ti6Al4V alloy: a review. Mater Design 164, 107552 (2019). doi: 10.1016/j.matdes.2018.107552 [171] Murr LE, Quinones SA, Gaytan SM, Lopez MI, Rodela A et al. Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications. J Mech Behav Biomed Mater 2, 20–32 (2009). doi: 10.1016/j.jmbbm.2008.05.004 [172] Thijs L, Verhaeghe F, Craeghs T, Van Humbeeck J, Kruth JP. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater 58, 3303–3312 (2010). doi: 10.1016/j.actamat.2010.02.004 [173] Krakhmalev P, Fredriksson G, Yadroitsava I, Kazantseva N, Du Plessis A et al. Deformation behavior and microstructure of Ti6Al4V manufactured by SLM. Phys Proced 83, 778–788 (2016). doi: 10.1016/j.phpro.2016.08.080 [174] Xu W, Brandt M, Sun S, Elambasseril J, Liu Q et al. Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition. Acta Mater 85, 74–84 (2015). doi: 10.1016/j.actamat.2014.11.028 [175] Losertová M, Kubeš V. Microstructure and mechanical properties of selective laser melted Ti6Al4V alloy. IOP Conf Ser:Mater Sci Eng 266, 012009 (2017). [176] Vilaro T, Colin C, Bartout JD. As-Fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall Mater Trans A 42, 3190–3199 (2011). doi: 10.1007/s11661-011-0731-y [177] Mertens A, Reginster S, Paydas H, Contrepois Q, Dormal T et al. Mechanical properties of alloy Ti–6Al–4V and of stainless steel 316L processed by selective laser melting: influence of out-of-equilibrium microstructures. Powder Metal 57, 184–189 (2014). doi: 10.1179/1743290114Y.0000000092 [178] Yan M, Xu W, Dargusch MS, Tang HP, Brandt M et al. Review of effect of oxygen on room temperature ductility of titanium and titanium alloys. Powder Metal 57, 251–257 (2014). doi: 10.1179/1743290114Y.0000000108 [179] Yu Q, Qi L, Tsuru T, Traylor R, Rugg D et al. Origin of dramatic oxygen solute strengthening effect in titanium. Science 347, 635–639 (2015). doi: 10.1126/science.1260485 [180] Facchini L, Magalini E, Robotti P, Molinari A, Höges S et al. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders. Rapid Prototyping J 16, 450–459 (2010). doi: 10.1108/13552541011083371 [181] Wysocki B, Maj P, Sitek R, Buhagiar J, Kurzydłowski KJ et al. Laser and electron beam additive manufacturing methods of fabricating titanium bone implants. Appl Sci 7, 657 (2017). doi: 10.3390/app7070657 [182] Simonelli M, Tse YY, Tuck C. The formation of α + β microstructure in as-fabricated selective laser melting of Ti–6Al–4V. J Mater Res 29, 2028–2035 (2014). doi: 10.1557/jmr.2014.166 [183] Qiu CL, Adkins NJE, Attallah MM. Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti–6Al–4V. Mater Sci Eng:A 578, 230–239 (2013). doi: 10.1016/j.msea.2013.04.099 [184] Saravanan M, Devaraju A, Venkateshwaran N, Krishnakumari A, Saarvesh J. A review on recent progress in coatings on AISI austenitic stainless steel. Mater Today:Proc 5, 14392–14396 (2018). doi: 10.1016/j.matpr.2018.03.024 [185] Kong DC, Ni XQ, Dong CF, Lei XW, Zhang L et al. Bio-functional and anti-corrosive 3D printing 316L stainless steel fabricated by selective laser melting. Mater Design 152, 88–101 (2018). doi: 10.1016/j.matdes.2018.04.058 [186] Wang YM, Voisin T, McKeown JT, Ye JC, Calta NP et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat Mater 17, 63–71 (2018). doi: 10.1038/nmat5021 [187] Zhong Y, Liu LF, Wikman S, Cui DQ, Shen ZJ. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J Nucl Mater 470, 170–178 (2016). doi: 10.1016/j.jnucmat.2015.12.034 [188] Saeidi K, Gao X, Lofaj F, Kvetkova L, Shen ZJ. Transformation of austenite to duplex austenite-ferrite assembly in annealed stainless steel 316L consolidated by laser melting. J Alloys Compd 633, 463–469 (2015). doi: 10.1016/j.jallcom.2015.01.249 [189] Kong DC, Ni XQ, Dong CF, Zhang L, Man C et al. Heat treatment effect on the microstructure and corrosion behavior of 316L stainless steel fabricated by selective laser melting for proton exchange membrane fuel cells. Electrochim Acta 276, 293–303 (2018). doi: 10.1016/j.electacta.2018.04.188 [190] Ni XQ, Kong DC, Wen Y, Zhang L, Wu WH et al. Anisotropy in mechanical properties and corrosion resistance of 316L stainless steel fabricated by selective laser melting. Int J Miner, Metall, Mater 26, 319–328 (2019). doi: 10.1007/s12613-019-1740-x [191] Kurzynowski T, Gruber K, Stopyra W, Kuźnicka B, Chlebus E. Correlation between process parameters, microstructure and properties of 316 L stainless steel processed by selective laser melting. Mater Sci Eng:A 718, 64–73 (2018). doi: 10.1016/j.msea.2018.01.103 [192] Mertens A, Reginster S, Contrepois Q, Dormal T, Lemaire O et al. Microstructures and mechanical properties of stainless steel aisi 316l processed by selective laser melting. Mater Sci Forum 783–786, 898–903 (2014). [193] Kong DC, Dong CF, Ni XQ, Zhang L, Yao JZ et al. Mechanical properties and corrosion behavior of selective laser melted 316L stainless steel after different heat treatment processes. J Mater Sci Technol 35, 1499–1507 (2019). doi: 10.1016/j.jmst.2019.03.003 [194] Stoll P, Spierings A, Wegener K. Impact of a process interruption on tensile properties of SS 316L parts and hybrid parts produced with selective laser melting. Int J Adv Manuf Technol 103, 367–376 (2019). doi: 10.1007/s00170-019-03560-1 [195] Blinn B, Klein M, Glassner C, Smaga M, Aurich JC et al. An investigation of the microstructure and fatigue behavior of additively manufactured AISI 316L stainless steel with regard to the influence of heat treatment. Metals 8, 220 (2018). doi: 10.3390/met8040220 [196] Yin YJ, Sun JQ, Guo J, Kan XF, Yang DC. Mechanism of high yield strength and yield ratio of 316 L stainless steel by additive manufacturing. Mater Sci Eng:A 744, 773–777 (2019). doi: 10.1016/j.msea.2018.12.092 [197] Wang GQ, Liu Q, Rao H, Liu HC, Qiu CL. Influence of porosity and microstructure on mechanical and corrosion properties of a selectively laser melted stainless steel. J Alloys Compd 831, 154815 (2020). doi: 10.1016/j.jallcom.2020.154815 [198] Jeon JM, Park JM, Yu JH, Kim JG, Seong Y et al. Effects of microstructure and internal defects on mechanical anisotropy and asymmetry of selective laser-melted 316L austenitic stainless steel. Mater Sci Eng:A 763, 138152 (2019). doi: 10.1016/j.msea.2019.138152 [199] Wu AS, Brown DW, Kumar M, Gallegos GF, King WE. An experimental investigation into additive manufacturing-induced residual stresses in 316L stainless steel. Metall Mater Trans A 45, 6260–6270 (2014). doi: 10.1007/s11661-014-2549-x [200] Amato KN, Gaytan SM, Murr LE, Martinez E, Shindo PW et al. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater 60, 2229–2239 (2012). doi: 10.1016/j.actamat.2011.12.032 [201] Hosseini E, Popovich VA. A review of mechanical properties of additively manufactured Inconel 718. Addit Manuf 30, 100877 (2019). [202] Yi JH, Kang JW, Wang TJ, Wang X, Feng T et al. Microstructure and mechanical behavior of bright crescent areas in Inconel 718 sample fabricated by selective laser melting. Mater Design 197, 109259 (2021). doi: 10.1016/j.matdes.2020.109259 [203] Qi H, Azer M, Ritter A. Studies of standard heat treatment effects on microstructure and mechanical properties of laser net shape manufactured INCONEL 718. Metall Mater Trans A 40, 2410–2422 (2009). doi: 10.1007/s11661-009-9949-3 [204] Paulonis DF, Schirra JJ. Alloy 718 at Pratt & Whitney-Historical perspective and future challenges. Superalloys 718, 13–23 (2001). [205] Aydinöz ME, Brenne F, Schaper M, Schaak C, Tillmann W et al. On the microstructural and mechanical properties of post-treated additively manufactured Inconel 718 superalloy under quasi-static and cyclic loading. Mater Sci Eng:A 669, 246–258 (2016). doi: 10.1016/j.msea.2016.05.089 [206] Kirka MM, Unocic KA, Raghavan N, Medina F, Dehoff RR et al. Microstructure development in electron beam-melted inconel 718 and associated tensile properties. JOM 68, 1012–1020 (2016). doi: 10.1007/s11837-016-1812-6 [207] Caiazzo F, Alfieri V, Corrado G, Argenio P. Laser powder-bed fusion of Inconel 718 to manufacture turbine blades. Int J Adv Manuf Technol 93, 4023–4031 (2017). doi: 10.1007/s00170-017-0839-3 [208] Li SM, Xiao H, Liu KY, Xiao WJ, Li YQ et al. Melt-pool motion, temperature variation and dendritic morphology of Inconel 718 during pulsed- and continuous-wave laser additive manufacturing: a comparative study. Mater Design 119, 351–360 (2017). doi: 10.1016/j.matdes.2017.01.065 [209] Du JH, Lu XD, Deng Q, Qu JL, Zhuang JY et al. High-temperature structure stability and mechanical properties of novel 718 superalloy. Mater Sci Eng: A 452–453, 584–591 (2007). [210] Bean GE, Witkin DB, McLouth TD, Pate DN, Zaldivar RJ. Effect of laser focus shift on surface quality and density of Inconel 718 parts produced via selective laser melting. Addit Manuf 22, 207–215 (2018). [211] Schneider J, Lund B, Fullen M. Effect of heat treatment variations on the mechanical properties of Inconel 718 selective laser melted specimens. Addit Manuf 21, 248–254 (2018). [212] Georgilas K, Khan RHU, Kartal ME. The influence of pulsed laser powder bed fusion process parameters on Inconel 718 material properties. Mater Sci Eng:A 769, 138527 (2020). doi: 10.1016/j.msea.2019.138527 [213] Popovich VA, Borisov EV, Popovich AA, Sufiiarov VS, Masaylo DV et al. Functionally graded Inconel 718 processed by additive manufacturing: crystallographic texture, anisotropy of microstructure and mechanical properties. Mater Design 114, 441–449 (2017). doi: 10.1016/j.matdes.2016.10.075 [214] Smith DH, Bicknell J, Jorgensen L, Patterson BM, Cordes NL et al. Microstructure and mechanical behavior of direct metal laser sintered Inconel alloy 718. Mater Characteriz 113, 1–9 (2016). doi: 10.1016/j.matchar.2016.01.003 [215] Chlebus E, Gruber K, Kuźnicka B, Kurzac J, Kurzynowski T. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting. Mater Sci Eng:A 639, 647–655 (2015). doi: 10.1016/j.msea.2015.05.035 [216] Ni M, Chen C, Wang XJ, Wang PW, Li RD et al. Anisotropic tensile behavior of in situ precipitation strengthened Inconel 718 fabricated by additive manufacturing. Mater Sci Eng:A 701, 344–351 (2017). doi: 10.1016/j.msea.2017.06.098 [217] Valdez M, Kozuch C, Faierson EJ, Jasiuk I. Induced porosity in Super Alloy 718 through the laser additive manufacturing process: microstructure and mechanical properties. J Alloys Compd 725, 757–764 (2017). doi: 10.1016/j.jallcom.2017.07.198 [218] Wang ZM, Guan K, Gao M, Li XY, Chen XF et al. The microstructure and mechanical properties of deposited-IN718 by selective laser melting. J Alloys Compd 513, 518–523 (2012). doi: 10.1016/j.jallcom.2011.10.107 [219] Moussaoui K, Rubio W, Mousseigne M, Sultan T, Rezai F. Effects of Selective Laser Melting additive manufacturing parameters of Inconel 718 on porosity, microstructure and mechanical properties. Mater Sci Eng:A 735, 182–190 (2018). [220] Lu YJ, Wu SQ, Gan YL, Huang TT, Yang CG et al. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt Laser Technol 75, 197–206 (2015). doi: 10.1016/j.optlastec.2015.07.009 [221] Polmear I, StJohn D, Nie JF, Qian M. Light Alloys: Metallurgy of the Light Metals 5th ed (Elsevier, Boston, 2017). [222] Tradowsky U, White J, Ward RM, Read N, Reimers W et al. Selective laser melting of AlSi10Mg: influence of post-processing on the microstructural and tensile properties development. Mater Design 105, 212–222 (2016). doi: 10.1016/j.matdes.2016.05.066 [223] Aboulkhair NT, Simonelli M, Parry L, Ashcroft I, Tuck C et al. 3D printing of Aluminium alloys: additive Manufacturing of Aluminium alloys using selective laser melting. Prog Mater Sci 106, 100578 (2019). doi: 10.1016/j.pmatsci.2019.100578 [224] Altıparmak SC, Yardley VA, Shi ZS, Lin JG. Challenges in additive manufacturing of high-strength aluminium alloys and current developments in hybrid additive manufacturing. Int J Lightw Mater Manuf 4, 246–261 (2021). [225] Martin JH, Yahata BD, Hundley JM, Mayer JA, Schaedler TA et al. 3D printing of high-strength aluminium alloys. Nature 549, 365–369 (2017). doi: 10.1038/nature23894 [226] Brandl E, Heckenberger U, Holzinger V, Buchbinder D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): microstructure, high cycle fatigue, and fracture behavior. Mater Design 34, 159–169 (2012). doi: 10.1016/j.matdes.2011.07.067 [227] Li W, Li S, Liu J, Zhang A, Zhou Y et al. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater Sci Eng:A 663, 116–125 (2016). doi: 10.1016/j.msea.2016.03.088 [228] Chen B, Moon SK, Yao X, Bi G, Shen J et al. Strength and strain hardening of a selective laser melted AlSi10Mg alloy. Scr Mater 141, 45–49 (2017). doi: 10.1016/j.scriptamat.2017.07.025 [229] Awd M, Stern F, Kampmann A, Kotzem D, Tenkamp J et al. Microstructural characterization of the anisotropy and cyclic deformation behavior of selective laser melted AlSi10Mg structures. Metals 8, 825 (2018). doi: 10.3390/met8100825 [230] Manfredi D, Calignano F, Krishnan M, Canali R, Ambrosio EP et al. From powders to dense metal parts: characterization of a commercial AlSiMg alloy processed through direct metal laser sintering. Materials 6, 856–869 (2013). doi: 10.3390/ma6030856 [231] Rosenthal I, Stern A, Frage N. Microstructure and mechanical properties of AlSi10Mg parts produced by the laser beam Additive Manufacturing (AM) technology. Metallogr, Microstruct, Anal 3, 448–453 (2014). doi: 10.1007/s13632-014-0168-y [232] Kempen K, Thijs L, Van Humbeeck J, Kruth JP. Processing AlSi10Mg by selective laser melting: parameter optimisation and material characterisation. Mater Sci Technol 31, 917–923 (2015). doi: 10.1179/1743284714Y.0000000702 [233] Anwar AB, Pham QC. Selective laser melting of AlSi10Mg: effects of scan direction, part placement and inert gas flow velocity on tensile strength. J Mater Process Technol 240, 388–396 (2017). doi: 10.1016/j.jmatprotec.2016.10.015 [234] Li X, Huang ZH, Qi WJ, Wang J, Li YJ et al. Microstructure and mechanical properties of AlSi10Mg alloy fabricated by SLM technology. Mater Sci 9, 564–572 (2019). [235] Kempen K, Thijs L, Van Humbeeck J, Kruth JP. Mechanical properties of AlSi10Mg produced by selective laser melting. Phys Proced 39, 439–446 (2012). doi: 10.1016/j.phpro.2012.10.059 [236] Fatemi A, Molaei R, Sharifimehr S, Phan N, Shamsaei N. Multiaxial fatigue behavior of wrought and additive manufactured Ti-6Al-4V including surface finish effect. Int J Fatigue 100, 347–366 (2017). doi: 10.1016/j.ijfatigue.2017.03.044 [237] Shrestha R, Simsiriwong J, Shamsaei N, Thompson SM, Bian LK. Effect of build orientation on the fatigue behavior of stainless steel 316L manufactured via a laser-powder bed fusion process. In 27th Annual Solid Frefform Fabrication Symposium Proceedings 605–616 (2016). [238] Raus AA, Wahab MS, Ibrahim M, Kamarudin K, Ahmed A et al. Mechanical and physical properties of AlSi10Mg processed through selective laser melting. AIP Conf Proc 1831, 020027 (2017). [239] Shi J, Wang YC. Development of metal matrix composites by laser-assisted additive manufacturing technologies: a review. J Mater Sci 55, 9883–9917 (2020). doi: 10.1007/s10853-020-04730-3 [240] Yadroitsev I, Bertrand P, Smurov I. Parametric analysis of the selective laser melting process. Appl Surf Sci 253, 8064–8069 (2007). doi: 10.1016/j.apsusc.2007.02.088 [241] Boley CD, Khairallah SA, Rubenchik AM. Calculation of laser absorption by metal powders in additive manufacturing. Appl Opt 54, 2477–2482 (2015). doi: 10.1364/AO.54.002477 [242] Irrinki H, Dexter M, Barmore B, Enneti R, Pasebani S et al. Effects of powder attributes and laser powder bed fusion (L-PBF) process conditions on the densification and mechanical properties of 17-4 PH stainless steel. JOM 68, 860–868 (2016). doi: 10.1007/s11837-015-1770-4 [243] Heeling T, Cloots M, Wegener K. Melt pool simulation for the evaluation of process parameters in selective laser melting. Addit Manuf 14, 116–125 (2017). [244] Bai YC, Yang YQ, Wang D, Zhang MK. Influence mechanism of parameters process and mechanical properties evolution mechanism of maraging steel 300 by selective laser melting. Mater Sci Eng:A 703, 116–123 (2017). doi: 10.1016/j.msea.2017.06.033 [245] Gu H, Wei C, Li L, Han QQ, Setchi R et al. Multi-physics modelling of molten pool development and track formation in multi-track, multi-layer and multi-material selective laser melting. Int J Heat Mass Trans 151, 119458 (2020). doi: 10.1016/j.ijheatmasstransfer.2020.119458 [246] Yu GQ, Gu DD, Dai DH, Xia MJ, Ma CL et al. On the role of processing parameters in thermal behavior, surface morphology and accuracy during laser 3D printing of aluminum alloy. J Phys D:Appl Phys 49, 135501 (2016). doi: 10.1088/0022-3727/49/13/135501 [247] Wang ZK, Yan WT, Liu WK, Liu MB. Powder-scale multi-physics modeling of multi-layer multi-track selective laser melting with sharp interface capturing method. Comput Mech 63, 649–661 (2019). doi: 10.1007/s00466-018-1614-5 [248] Yan WT, Lian YP, Yu C, Kafka OL, Liu ZL et al. An integrated process–structure–property modeling framework for additive manufacturing. Comput Methods Appl Mech Eng 339, 184–204 (2018). doi: 10.1016/j.cma.2018.05.004 [249] Yang M, Wang L, Yan WT. Phase-field modeling of grain evolutions in additive manufacturing from nucleation, growth, to coarsening. npj Comput Mater 7, 56 (2021). doi: 10.1038/s41524-021-00524-6 [250] Simonelli M, Tse YY, Tuck C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V. Mater Sci Eng:A 616, 1–11 (2014). doi: 10.1016/j.msea.2014.07.086 [251] Chen CP, Yin J, Zhu HH, Xiao ZX, Zhang L et al. Effect of overlap rate and pattern on residual stress in selective laser melting. Int J Mach Tools Manu 145, 103433 (2019). doi: 10.1016/j.ijmachtools.2019.103433 [252] Chen CY, Xie YC, Yan XC, Yin S, Fukanuma H et al. Effect of hot isostatic pressing (HIP) on microstructure and mechanical properties of Ti6Al4V alloy fabricated by cold spray additive manufacturing. Addit Manuf 27, 595–605 (2019). [253] Atkinson HV, Davies S. Fundamental aspects of hot isostatic pressing: an overview. Metall Mater Trans A 31, 2981–3000 (2000). doi: 10.1007/s11661-000-0078-2 [254] Finfrock CB, Exil A, Carroll JD, Deibler L. Effect of hot isostatic pressing and powder feedstock on porosity, microstructure, and mechanical properties of selective laser melted AlSi10Mg. Metallogr, Microstruct, Anal 7, 443–456 (2018). doi: 10.1007/s13632-018-0456-z [255] Haan J, Asseln M, Zivcec M, Eschweiler J, Radermacher R et al. Effect of subsequent Hot Isostatic Pressing on mechanical properties of ASTM F75 alloy produced by Selective Laser Melting. Powder Metal 58, 161–165 (2015). doi: 10.1179/0032589915Z.000000000236 [256] Leuders S, Lieneke T, Lammers S, Tröster T, Niendorf T. On the fatigue properties of metals manufactured by selective laser melting — the role of ductility. J Mater Res 29, 1911–1919 (2014). doi: 10.1557/jmr.2014.157 [257] Schneller W, Leitner M, Springer S, Grün F, Taschauer M. Effect of HIP treatment on microstructure and fatigue strength of selectively laser melted AlSi10Mg. J Manuf Mater Process 3, 16 (2019). [258] Grzesik W. Hybrid additive and subtractive manufacturing processes and systems: a review. J Mach Eng 18, 5–24 (2018). [259] Gibson I, Rosen D, Stucker B, Khorasani M. Hybrid additive manufacturing. Gibson I, Rosen D, Stucker B, Khorasani M, eds. Additive Manufacturing Technologies, 347–366 (Springer, Cham, 2021); https://doi.org/10.1007/978-3-030-56127-7_12. [260] Everton SK, Hirsch M, Stravroulakis P, Leach RK, Clare AT. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater Design 95, 431–445 (2016). doi: 10.1016/j.matdes.2016.01.099 [261] Bisht M, Ray N, Verbist F, Coeck S. Correlation of selective laser melting-melt pool events with the tensile properties of Ti-6Al-4V ELI processed by laser powder bed fusion. Addit Manuf 22, 302–306 (2018). [262] Tapia G, Elwany A. A review on process monitoring and control in metal-based additive manufacturing. J Manuf Sci Eng 136, 060801 (2014). doi: 10.1115/1.4028540 [263] Purtonen T, Kalliosaari A, Salminen A. Monitoring and adaptive control of laser processes. Phys Proced 56, 1218–1231 (2014). doi: 10.1016/j.phpro.2014.08.038 [264] Furumoto T, Alkahari MR, Ueda T, Aziz MSA, Hosokawa A. Monitoring of laser consolidation process of metal powder with high speed video camera. Phys Proced 39, 760–766 (2012). doi: 10.1016/j.phpro.2012.10.098 [265] Clijsters S, Craeghs T, Buls S, Kempen K, Kruth JP. In situ quality control of the selective laser melting process using a high-speed, real-time melt pool monitoring system. Int J Adv Manuf Technol 75, 1089–1101 (2014). doi: 10.1007/s00170-014-6214-8 [266] Renken V, Von Freyberg A, Schünemann K, Pastors F, Fischer A. In-process closed-loop control for stabilising the melt pool temperature in selective laser melting. Prog Addit Manuf 4, 411–421 (2019). doi: 10.1007/s40964-019-00083-9 [267] Wei KW, Lv M, Zeng XY, Xiao ZX, Huang G et al. Effect of laser remelting on deposition quality, residual stress, microstructure, and mechanical property of selective laser melting processed Ti-5Al-2.5Sn alloy. Mater Characteriz 150, 67–77 (2019). doi: 10.1016/j.matchar.2019.02.010 [268] Chua CK, Wong CH, Yeong WY. Standards, Quality Control, and Measurement Sciences in 3D Printing and Additive Manufacturing (Academic Press, London, 2017). [269] Mancisidor AM, Garciandia F, Sebastian MS, Álvarez P, Díaz J et al. Reduction of the residual porosity in parts manufactured by selective laser melting using skywriting and high focus offset strategies. Phys Proced 83, 864–873 (2016). doi: 10.1016/j.phpro.2016.08.090 -

Access History

Article Metrics

-

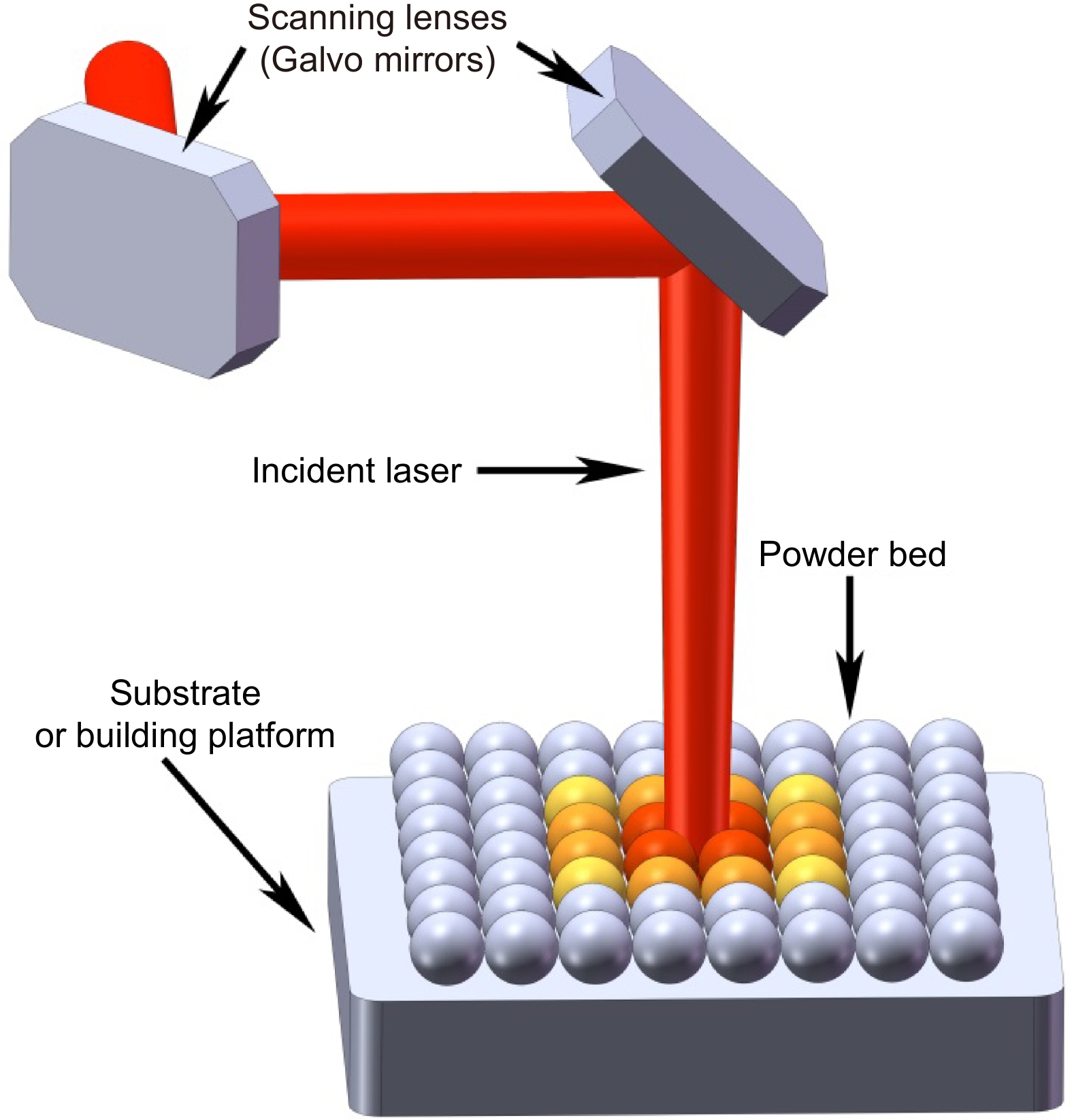

Figure 1.

Schematic illustration of LPBF processing.

-

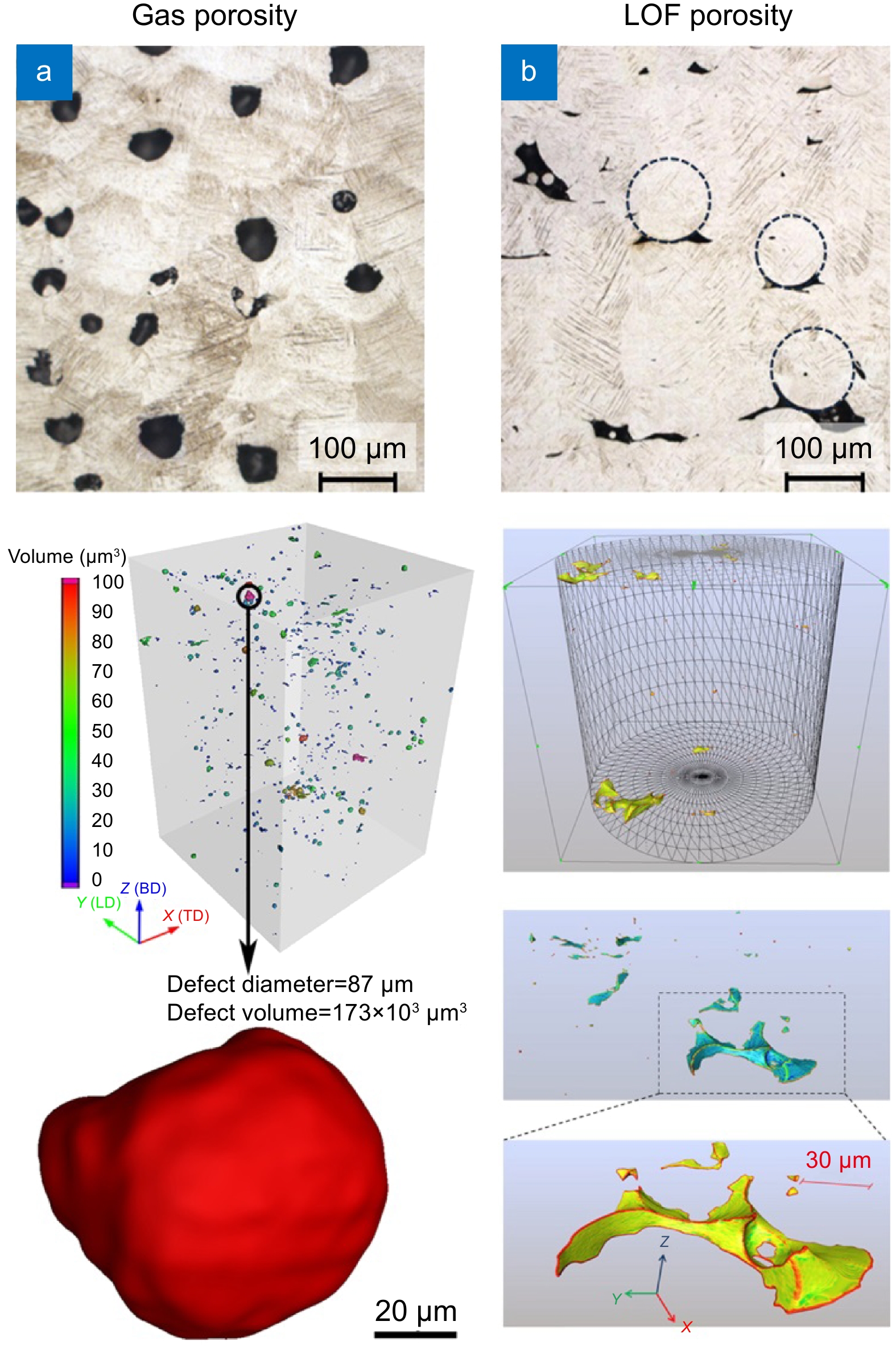

Figure 2.

Representative cross-sections and 3D reconstructions of (a) gas porosity and (b) LOF porosity detected in LPBF printed metals. The dashed circles in (b) indicate unmelted feedstock powder. Figure reproduced with permission from (a) ref.37,43, Elsevier; (b) ref.43, Elsevier, under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

-

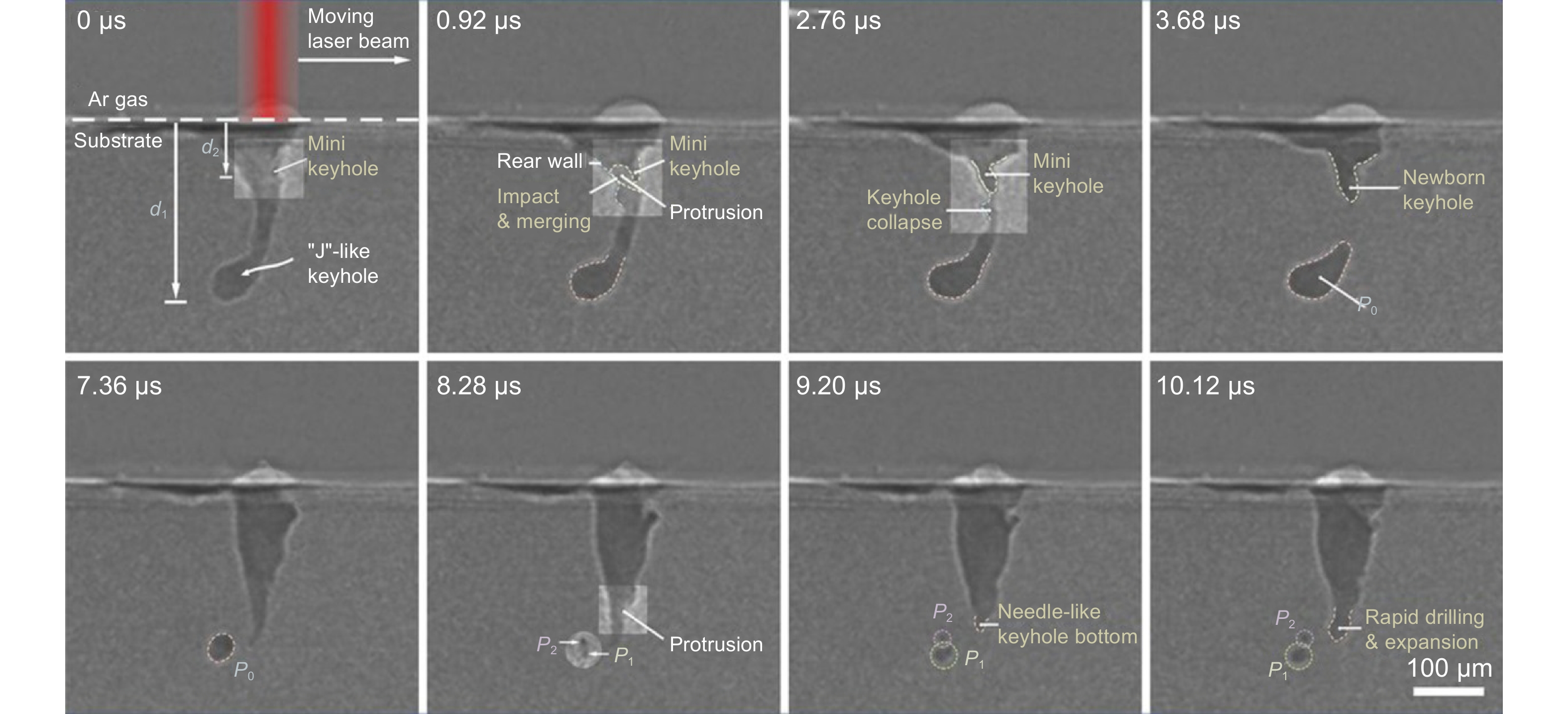

Figure 3.

Synchrotron X-ray images of pores generated from keyholes. The time marks represent the delays of each graph after the first shot. Figure reproduced with permisson from ref.29, The American Association for the Advancement of Science.

-

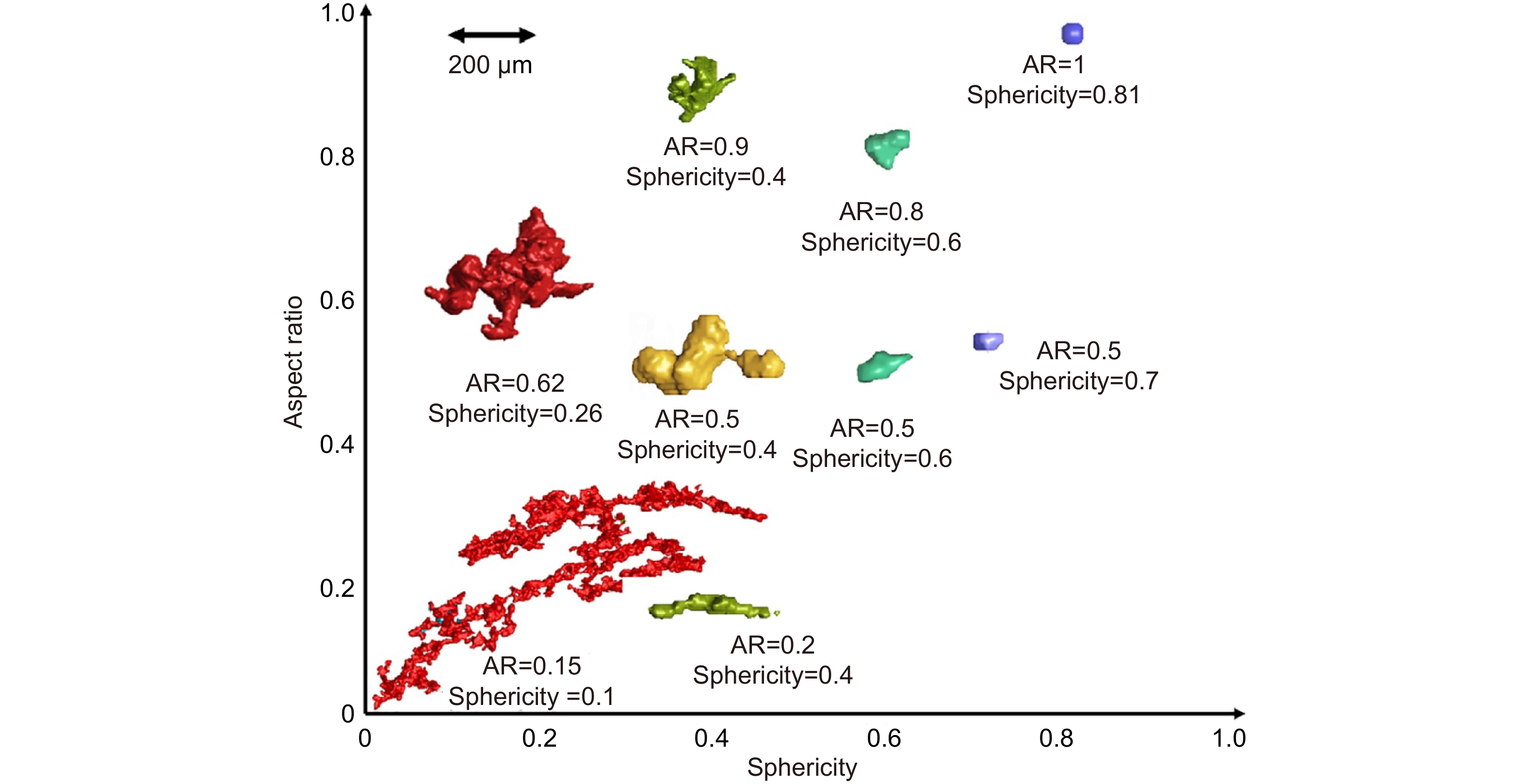

Figure 4.

Porosity detected in LPBF printed Ti−6Al−4V alloy, with respective AR and sphericity values. Figure reproduced with permission from ref.84, under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

-

Figure 5.

Representative 3D reconstructions of (a) the distribution of porosity in a Ti−6Al−4V sample and (b) views of a specific pore. Figure reproduced with permission from: (a) ref.101, Springer Nature. (b) ref.44, Elsevier.

-

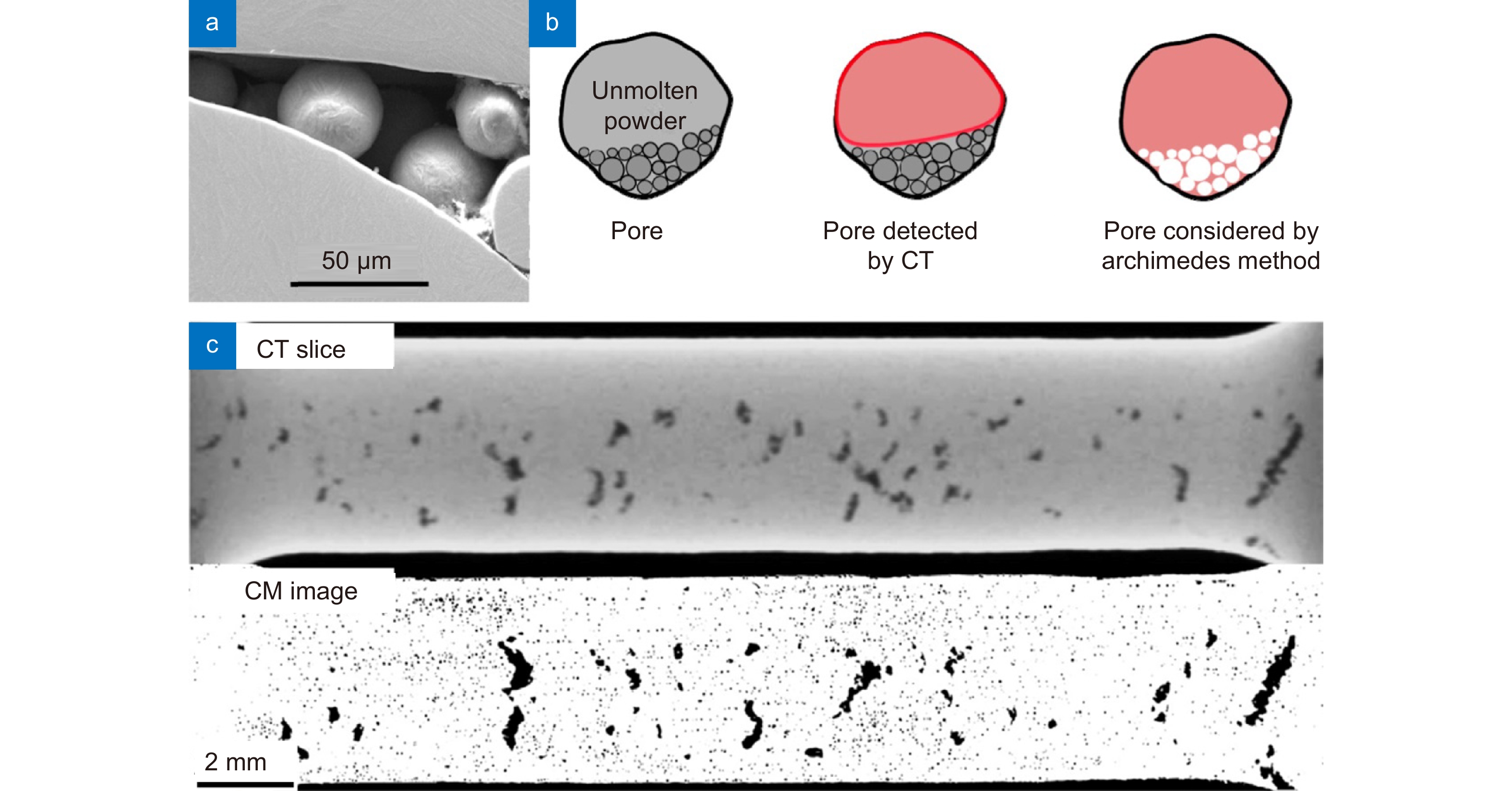

Figure 6.

Comparative illustration of the limitations of X-ray CT. (a) Microscopic image of a LOF pore; (b) comparison of pores detected using X-ray CT and the Archimedes method; and (c) comparison of the same cross-section in a 316L sample detected by CT and by confocal microscopy (CM). Figure reproduced with permission from: (a, b) ref.76, Elsevier; (c) ref.104, under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

-

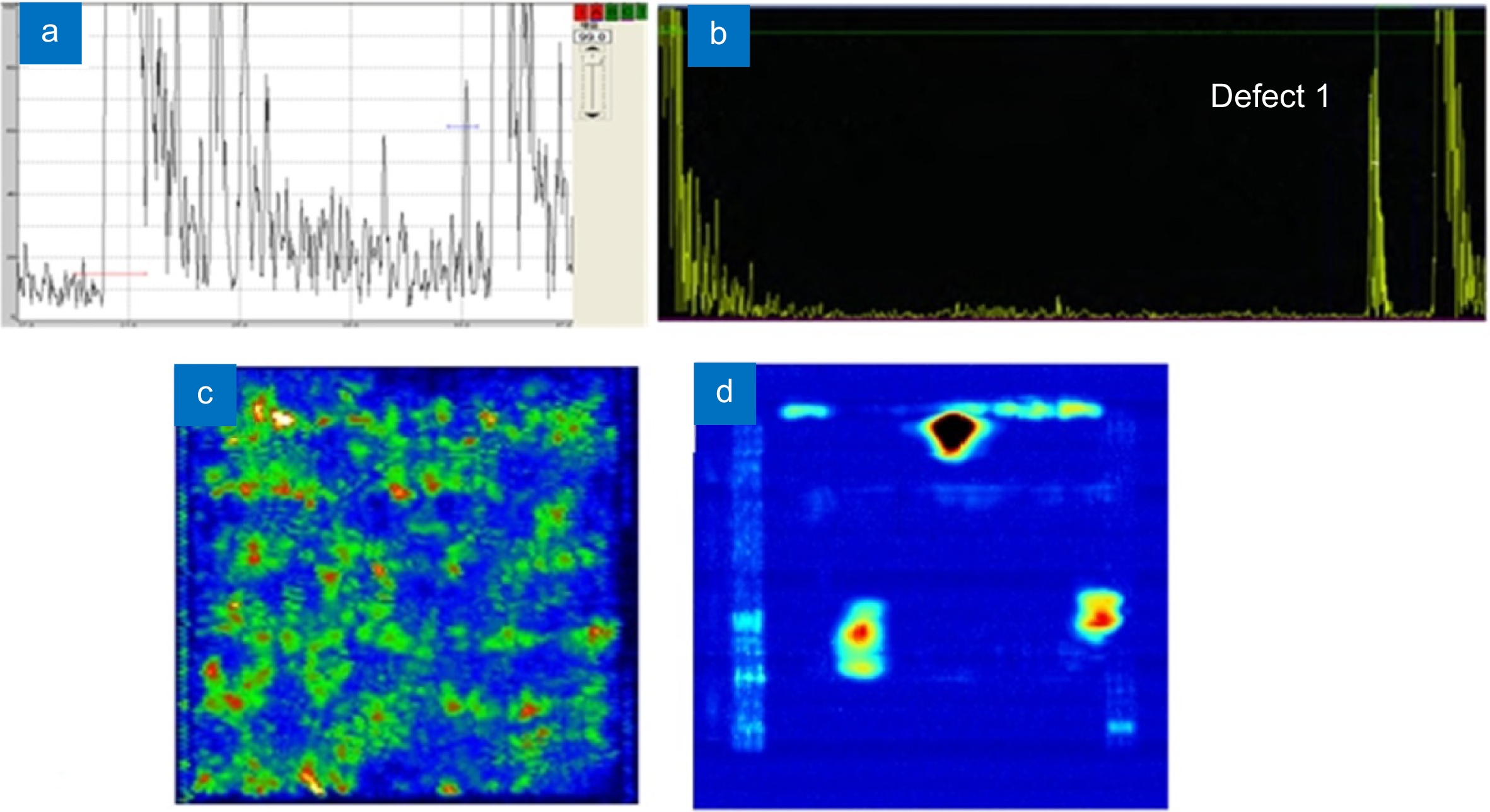

Figure 7.

1D ultrasonic A-scan diagrams of (a) conventional UT and (b) phased array UT; and 2D ultrasonic C-scan images of (c) conventional UT and (d) phased array UT. Figure reproduced from ref.117, under a Creative Commons Attribution 4.0 International License.

-

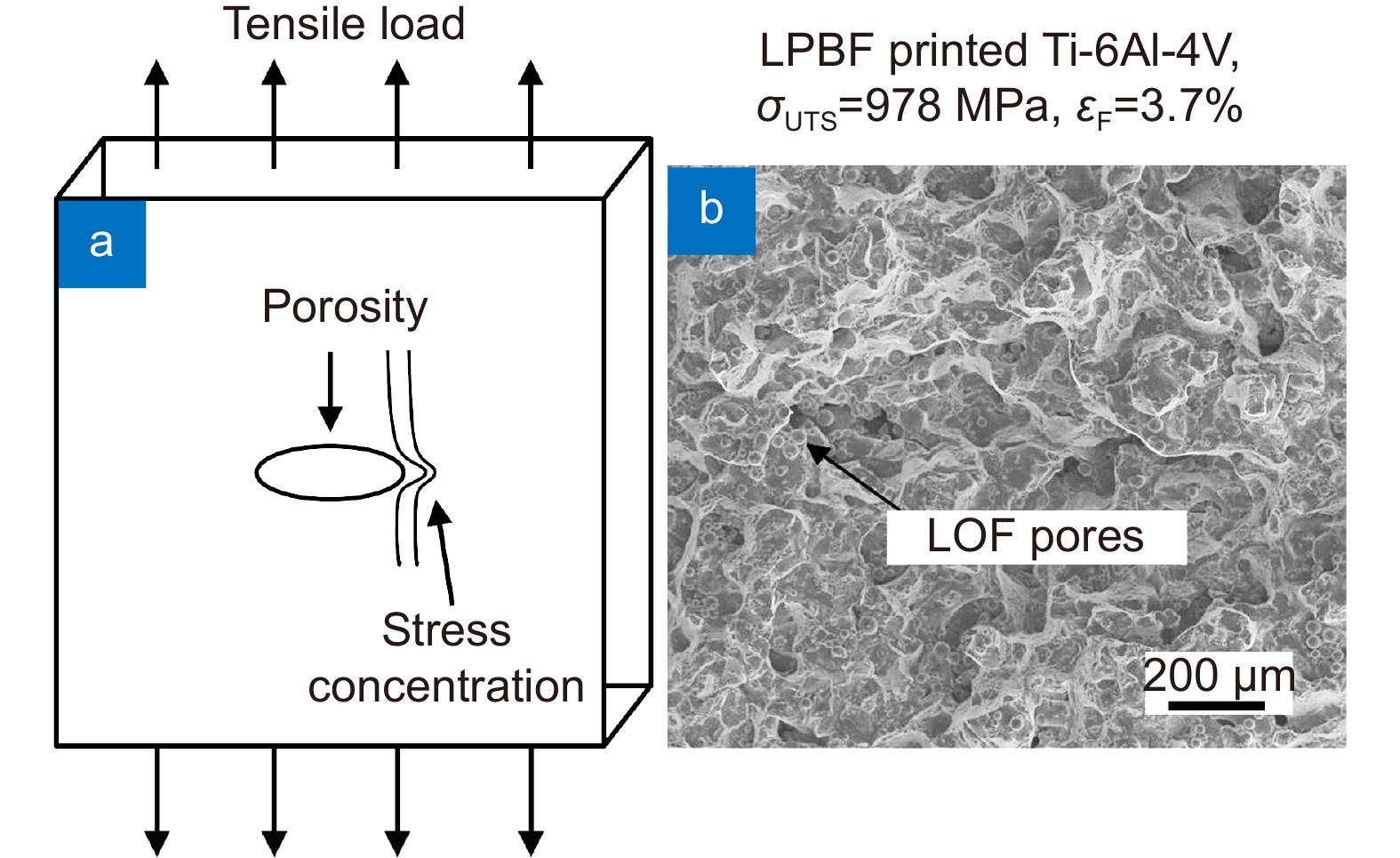

Figure 8.

Detriments of porosity to the mechanical performance. (a) Schematic illustration of uniaxial tensile load applied to a sample with inner porosity; (b) fractographic image of a LPBF printed Ti−6Al−4V tensile sample. Figure reproduced with permission from (b) ref.123, Elsevier.

-

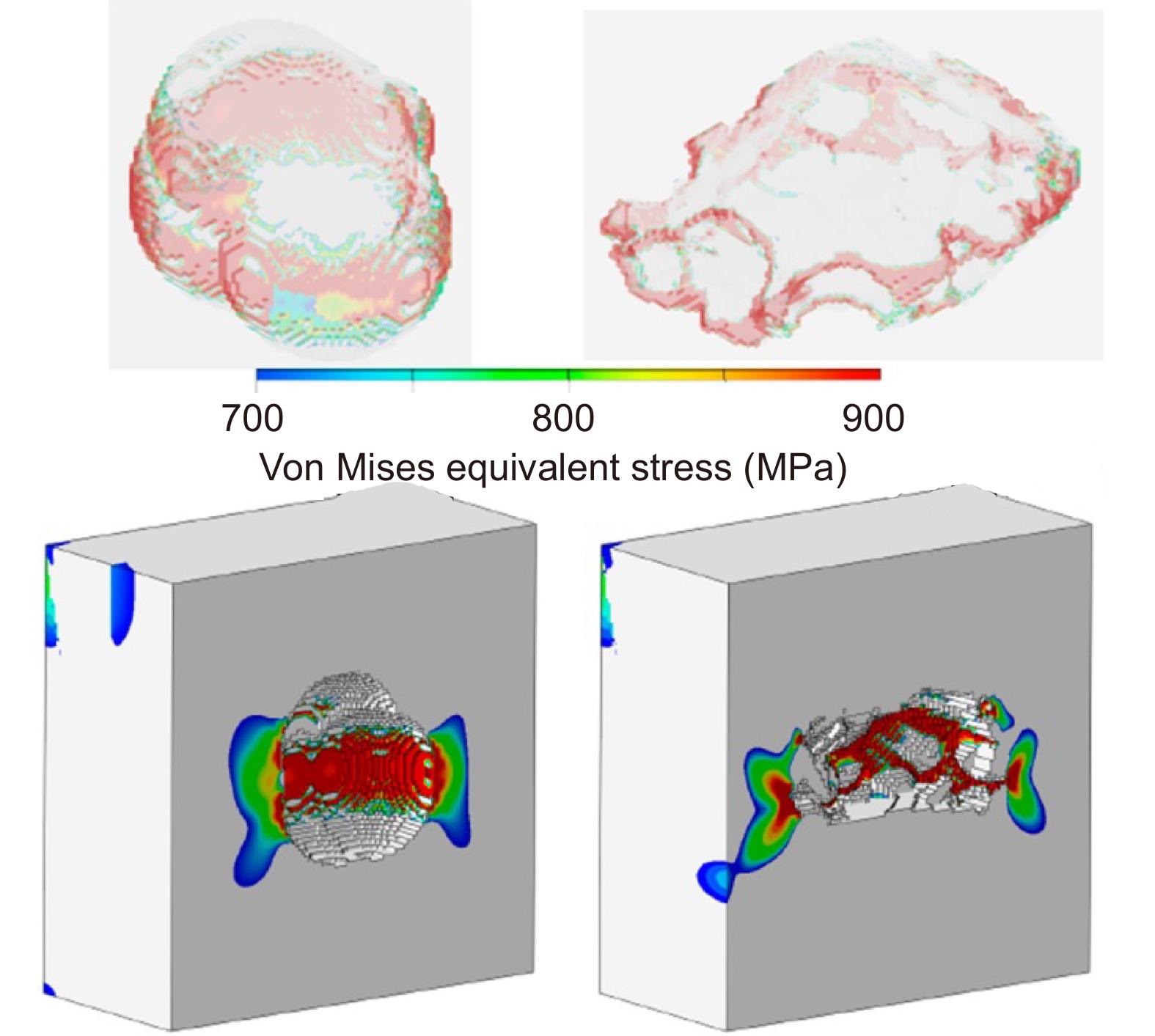

Figure 9.

Simulated stress distribution profile of two pores in a LPBF printed Ti−6Al−4V sample under identical uniaxial tensile load. Figure reproduced from ref.90, under a Creative Commons Attribution 4.0 International License.

-

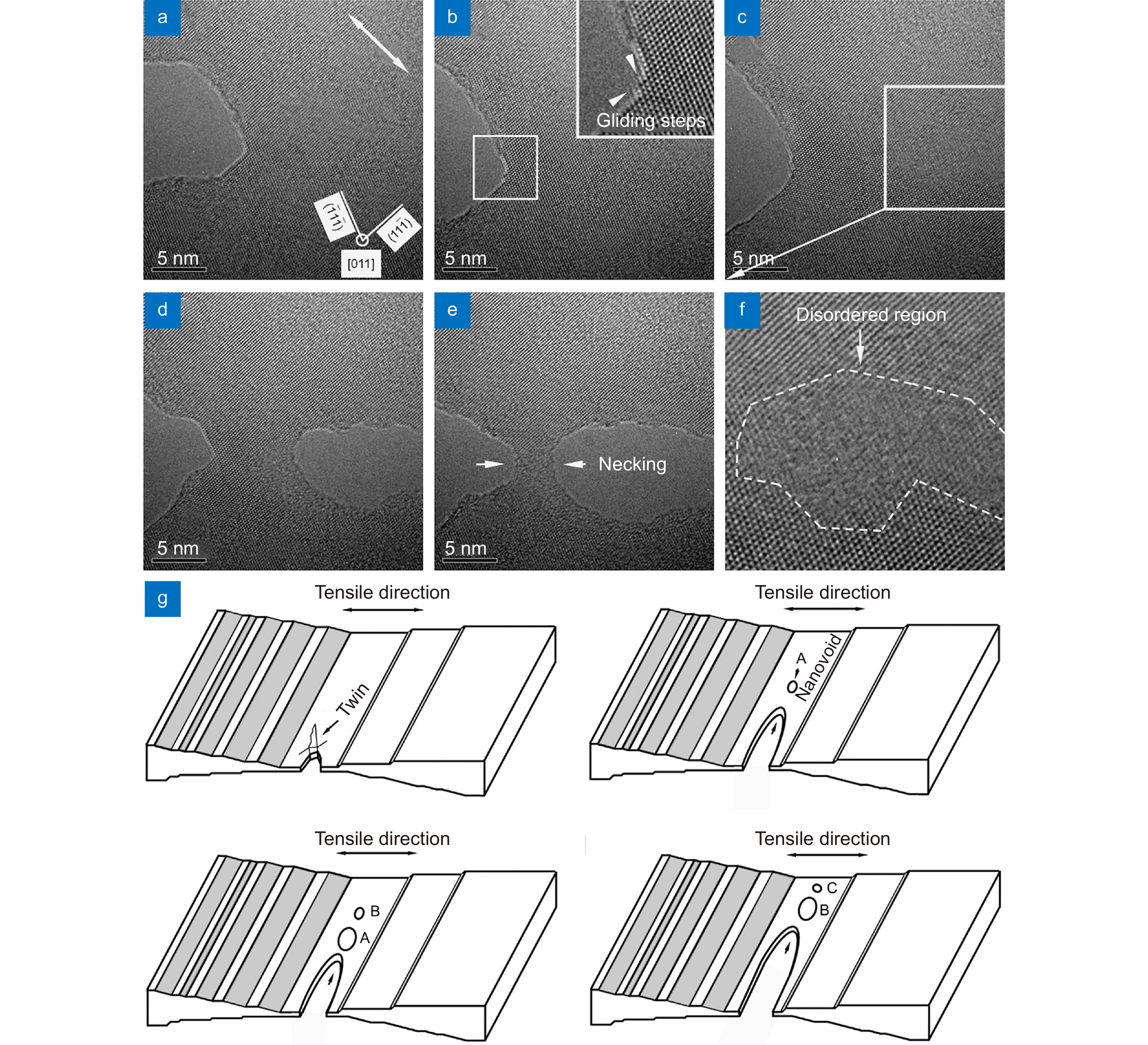

Figure 10.

Void growth and coalescence under tensile load. (a−f) High-resolution transmission electron microscopic images presenting the void growth and coalescence during in-situ tensile loading of an Al–Cu–Mg sample, with (g) corresponding schematic illustration. Figure reproduced with permission from ref.136, Elsevier.

-

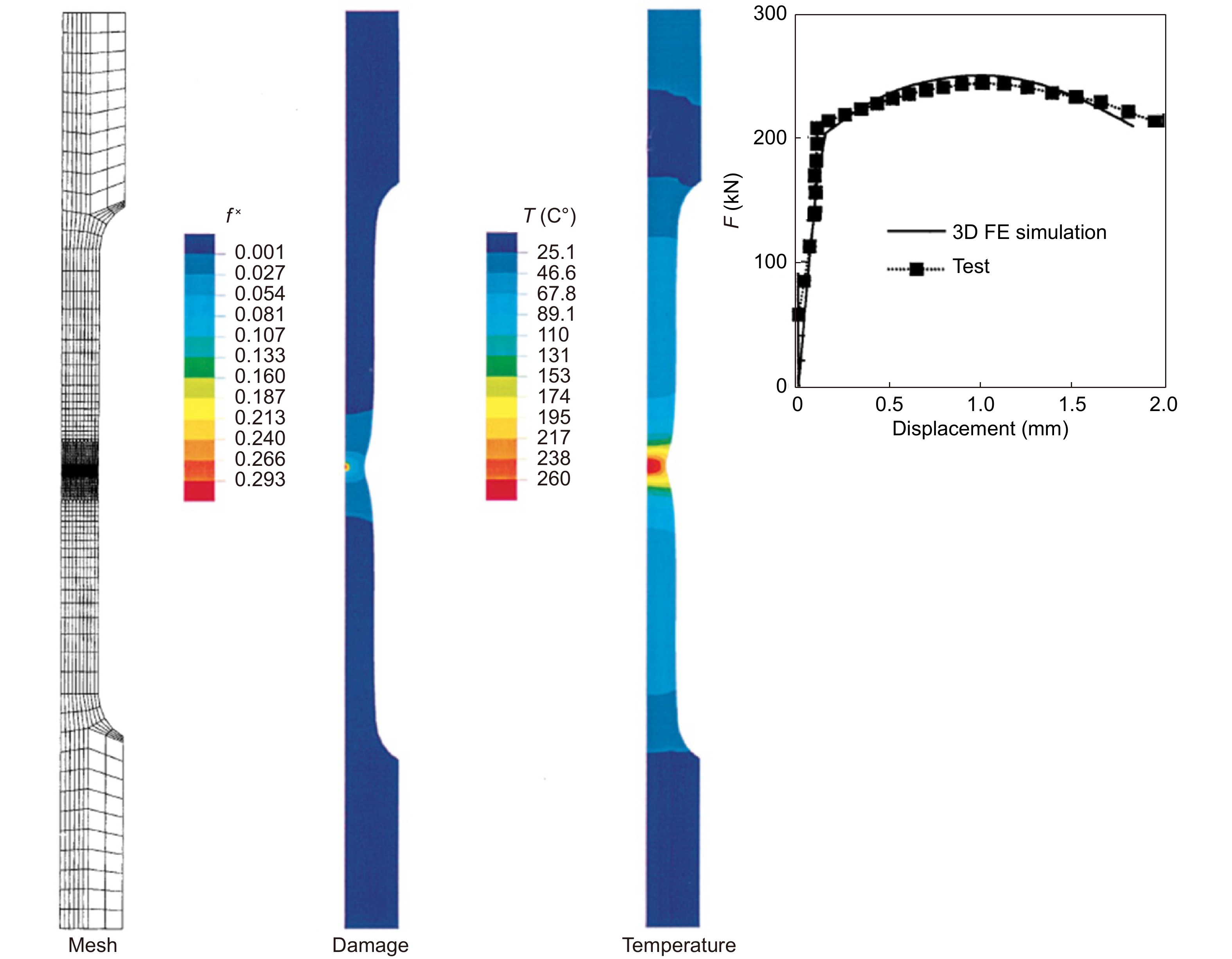

Figure 11.

FEM simulation of uniaxial tensile tests and corresponding comparison between experimental and predicted data of a 22NiMoCr37 steel sample; the mesh is installed with cylindrical voids. Figure reproduced with permission from ref.146, Springer Nature.

-

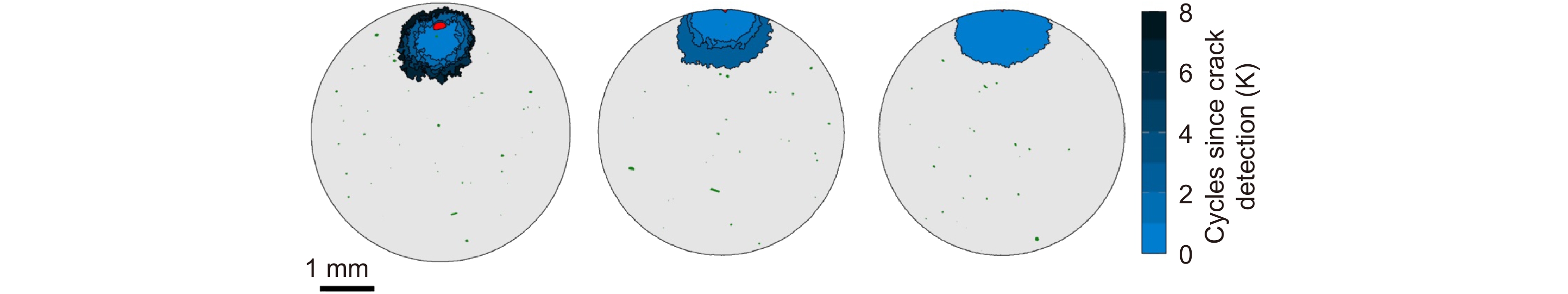

Figure 12.

Fatigue crack propagation detected by CT in three LPBF printed Ti−6Al−4V samples. The red regions indicate the pores as the initiation sites of fatigue cracks. Figure reproduced with permission from ref.150, under a Creative Commons Attribution 4.0 International License.

-

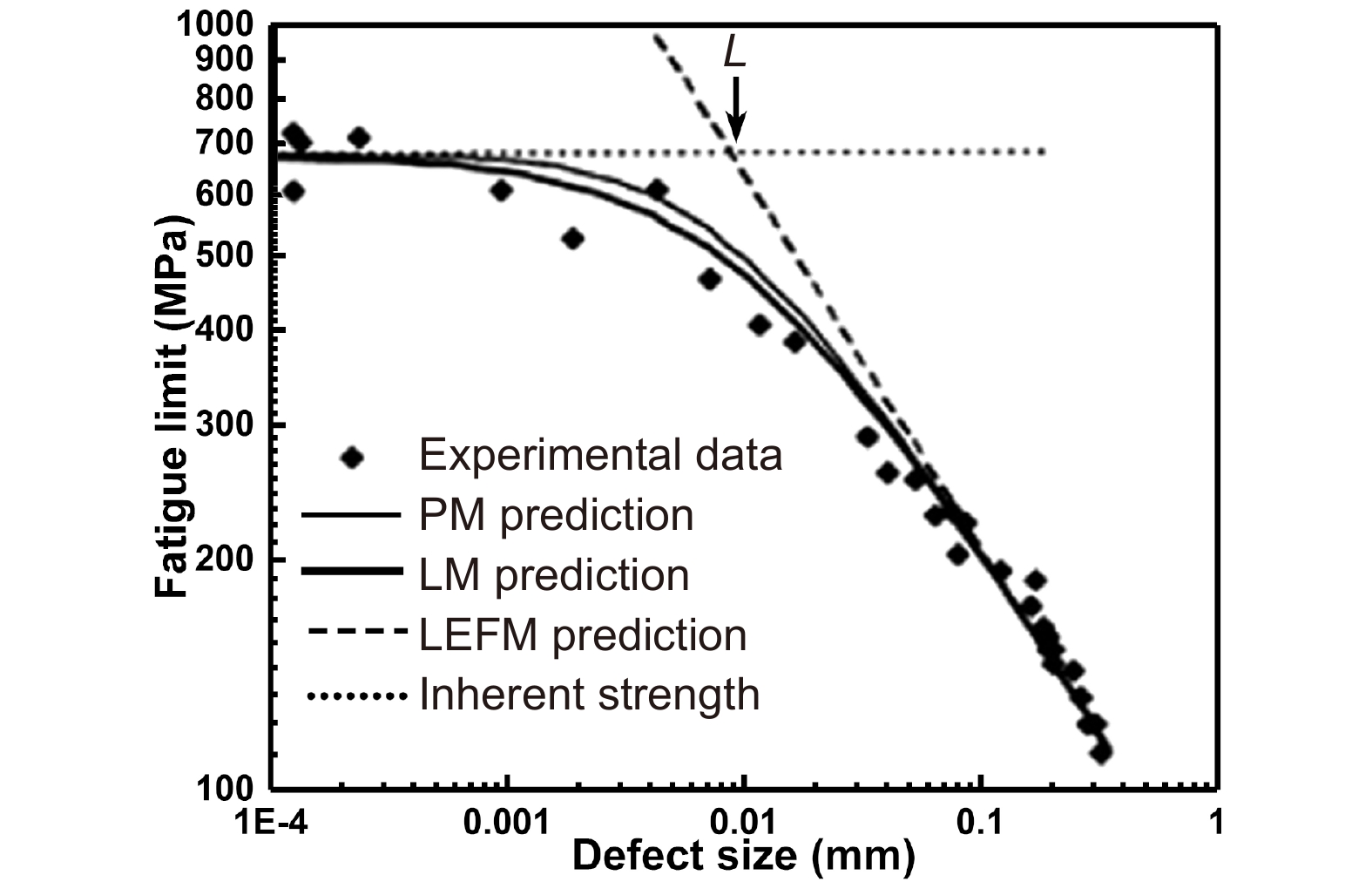

Figure 13.

Experimental and predicted fatigue limits of silicon carbide samples against defect size. PM, LM, and LEFM are acronyms of point method, line method, and linear elastic fracture mechanics, respectively. Figure reproduced with permission from ref.154, Elsevier.

-

Figure 14.

Designation of the testing directions.

-

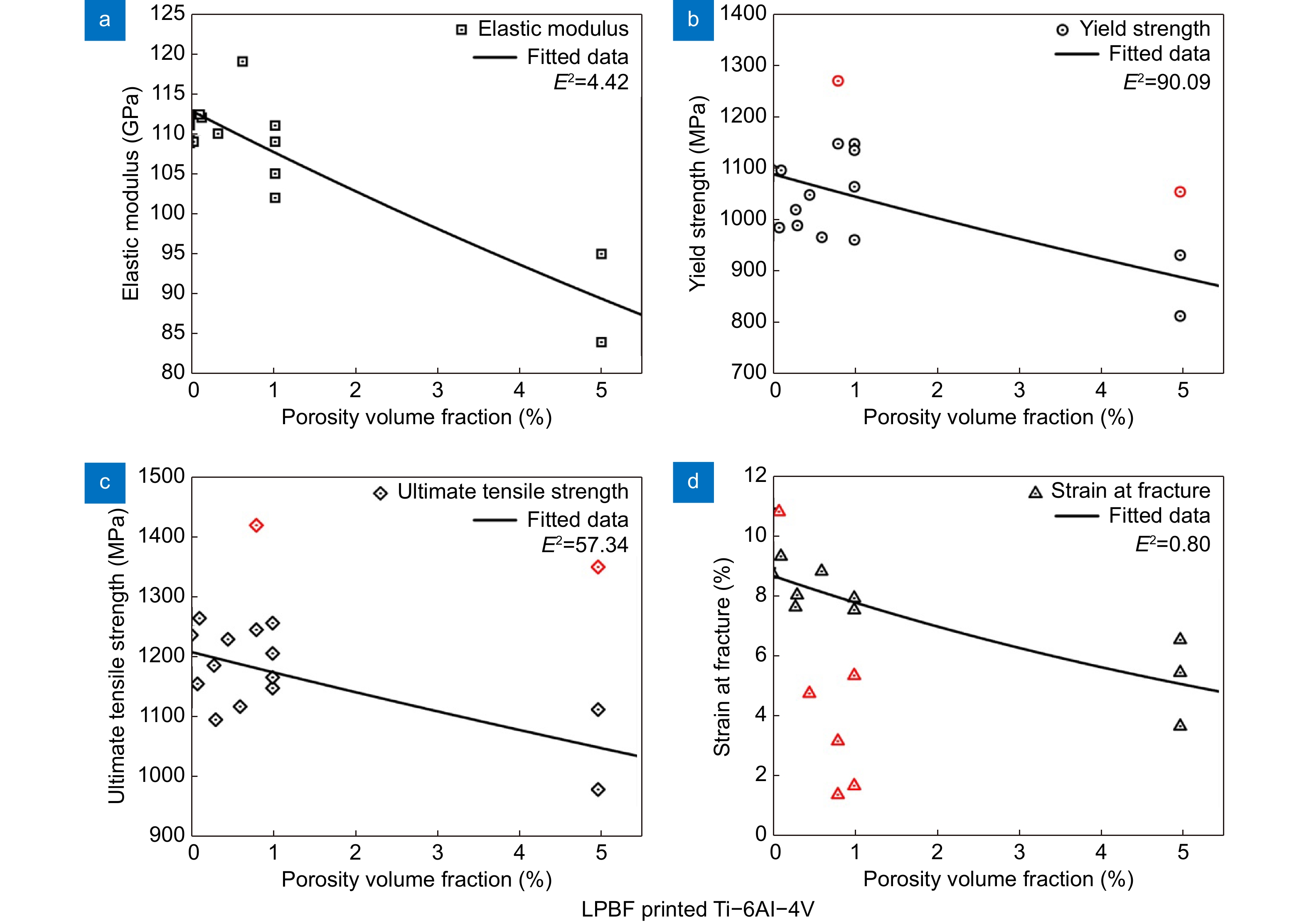

Figure 15.

Summarized tensile properties of LPBF printed Ti−6Al−4V versus porosity fraction, with corresponding phenomenological models. The red data spots are outliers that excluded from fitting.

-

Figure 16.

Summarized tensile properties of LPBF printed 316L SS versus porosity fraction, with corresponding phenomenological models. The red data spots are outliers that excluded from fitting.

-

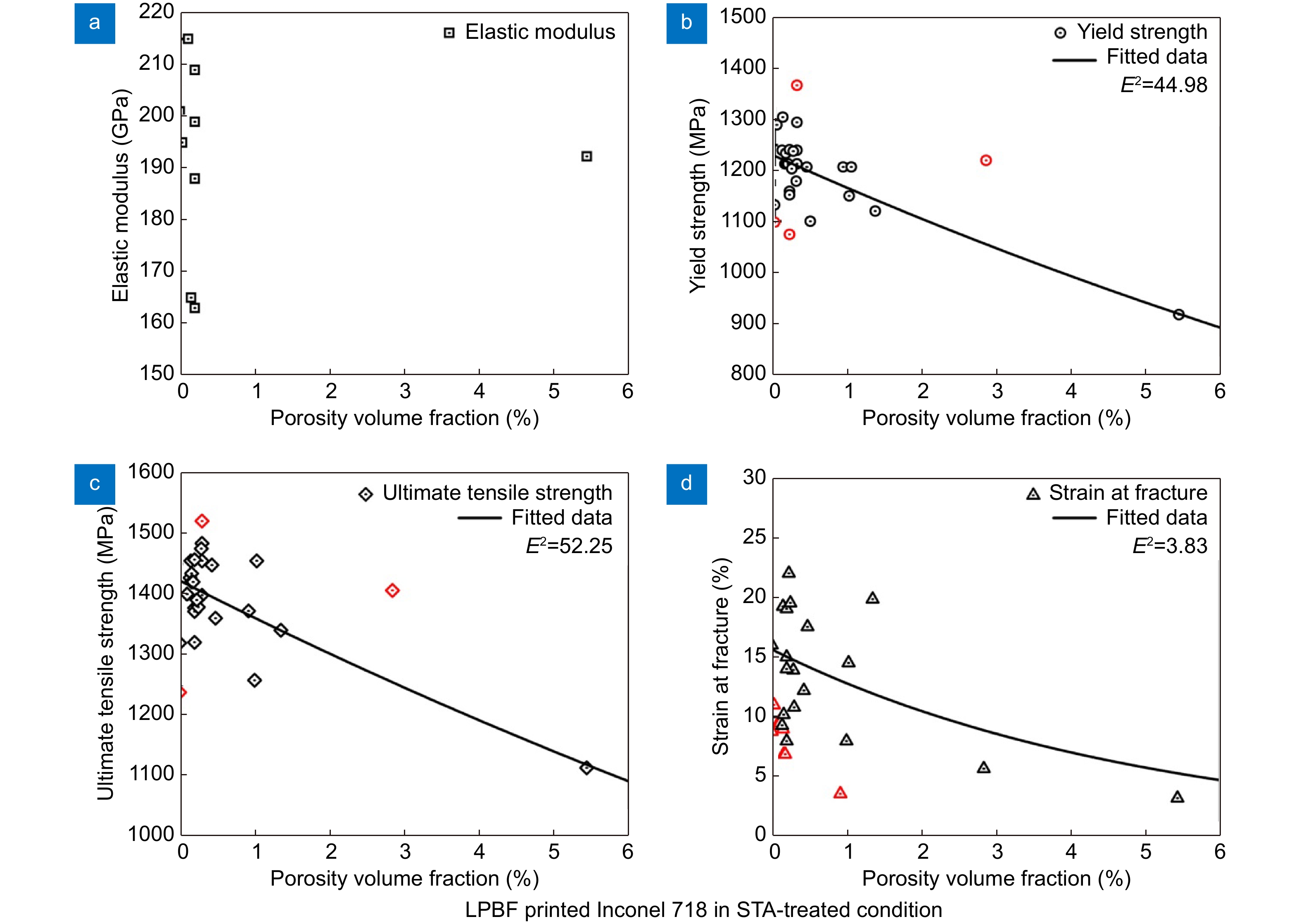

Figure 17.

Summarized tensile properties of LPBF printed Inconel 718 versus porosity fraction, with corresponding phenomenological models. The red data spots are outliers that excluded from fitting.

-

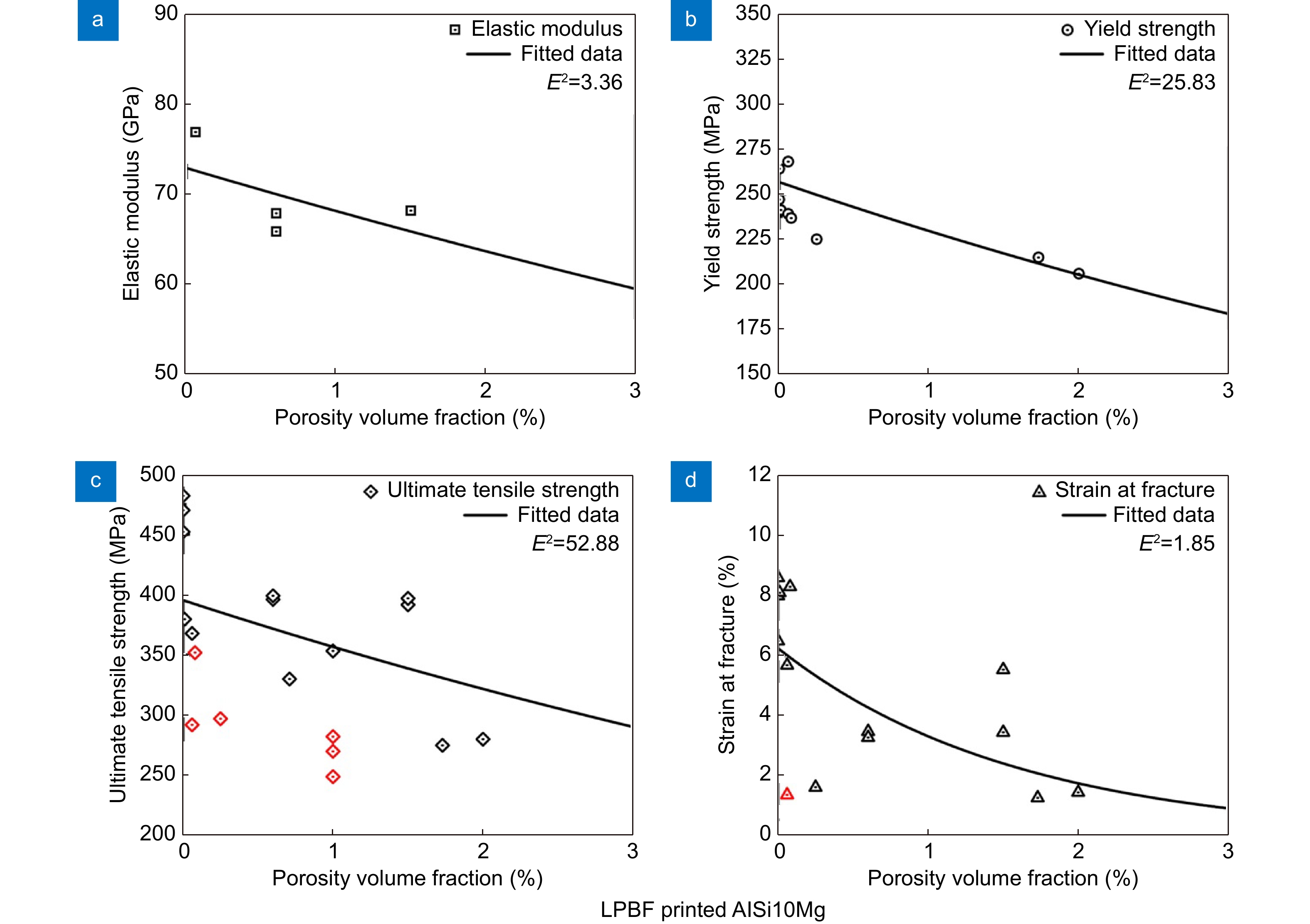

Figure 18.

Summarized tensile properties of LPBF printed AlSi10Mg versus porosity fraction, with corresponding phenomenological models. The red data spots are outliers that excluded from fitting.

-

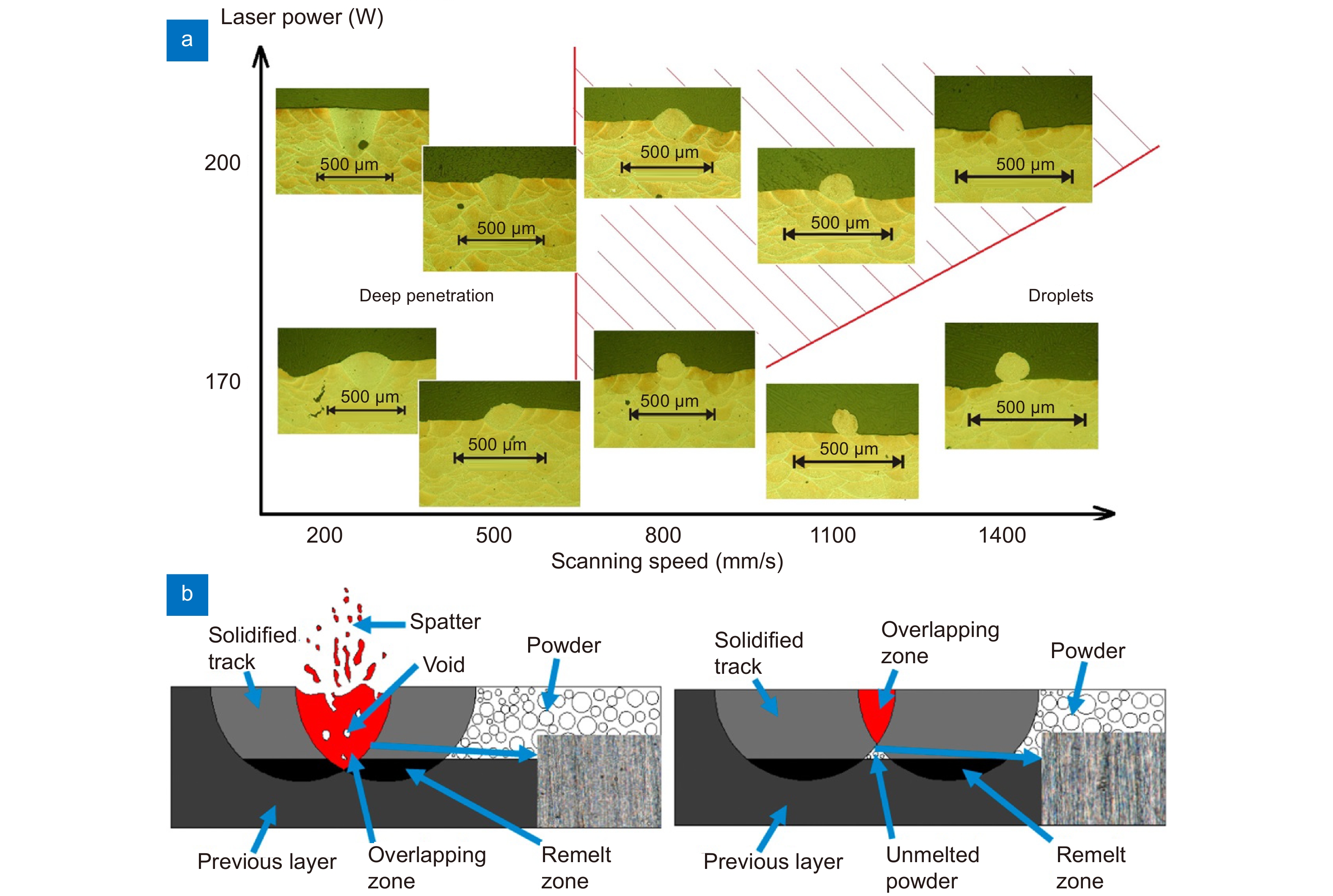

Figure 19.

The influence of LPBF processing parameters. (a) Cross-sections of single scan tracks of LPBF printed AlSi10Mg; (b) schematic illustration of the porosity formation due to inappropriate overlap rates. Figure reproduced with permission from: (a) ref.232, Taylor & Francis; (b) ref.244, Elsevier.

-

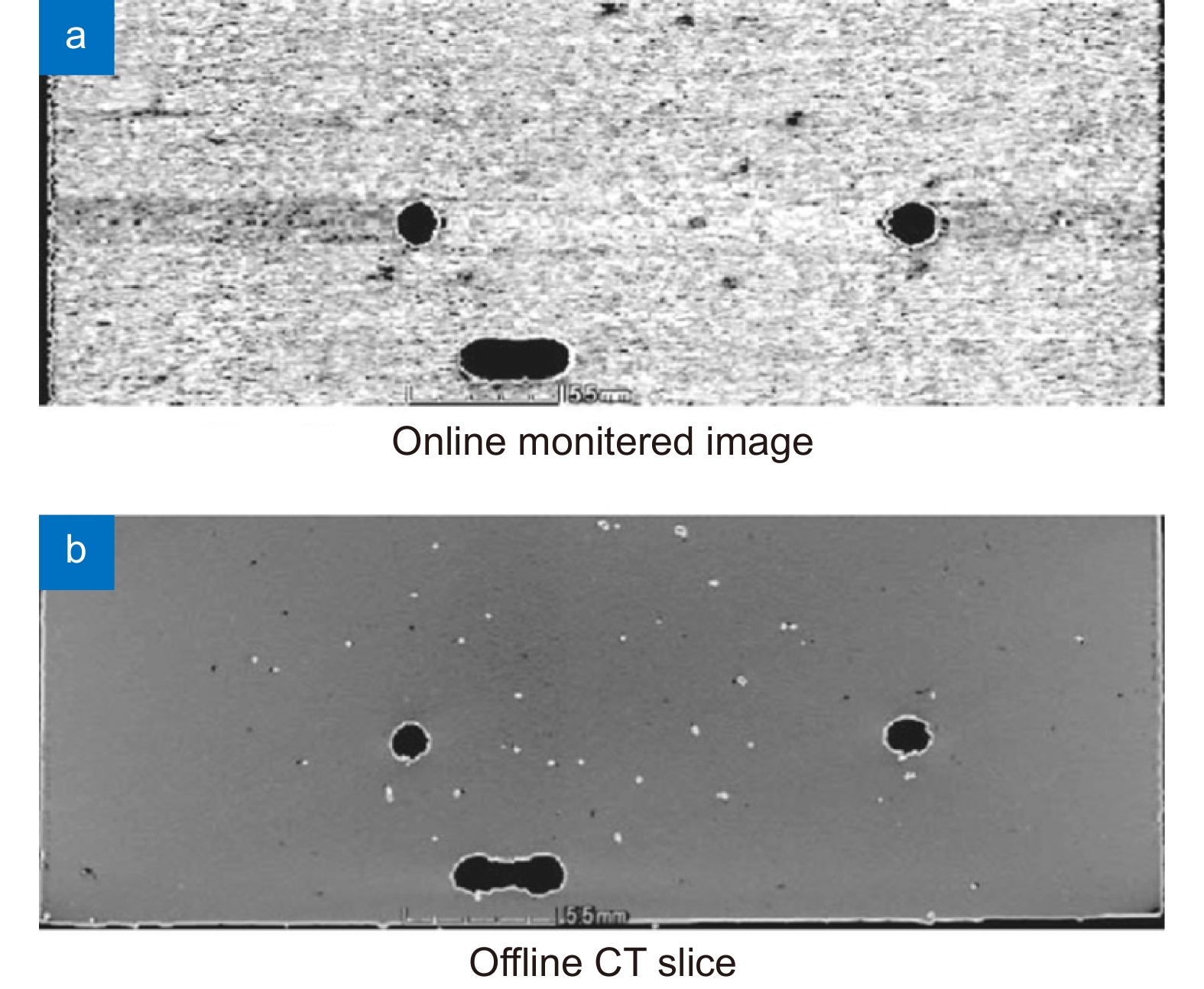

Figure 20.

Comparison between online monitoring and offline CT images. (a) The image acquired through online optical monitoring and (b) the offline CT slice at the same layer of a LPBF printed AlSi10Mg sample. Figure reproduced with permission from ref.265, Springer Nature.

-

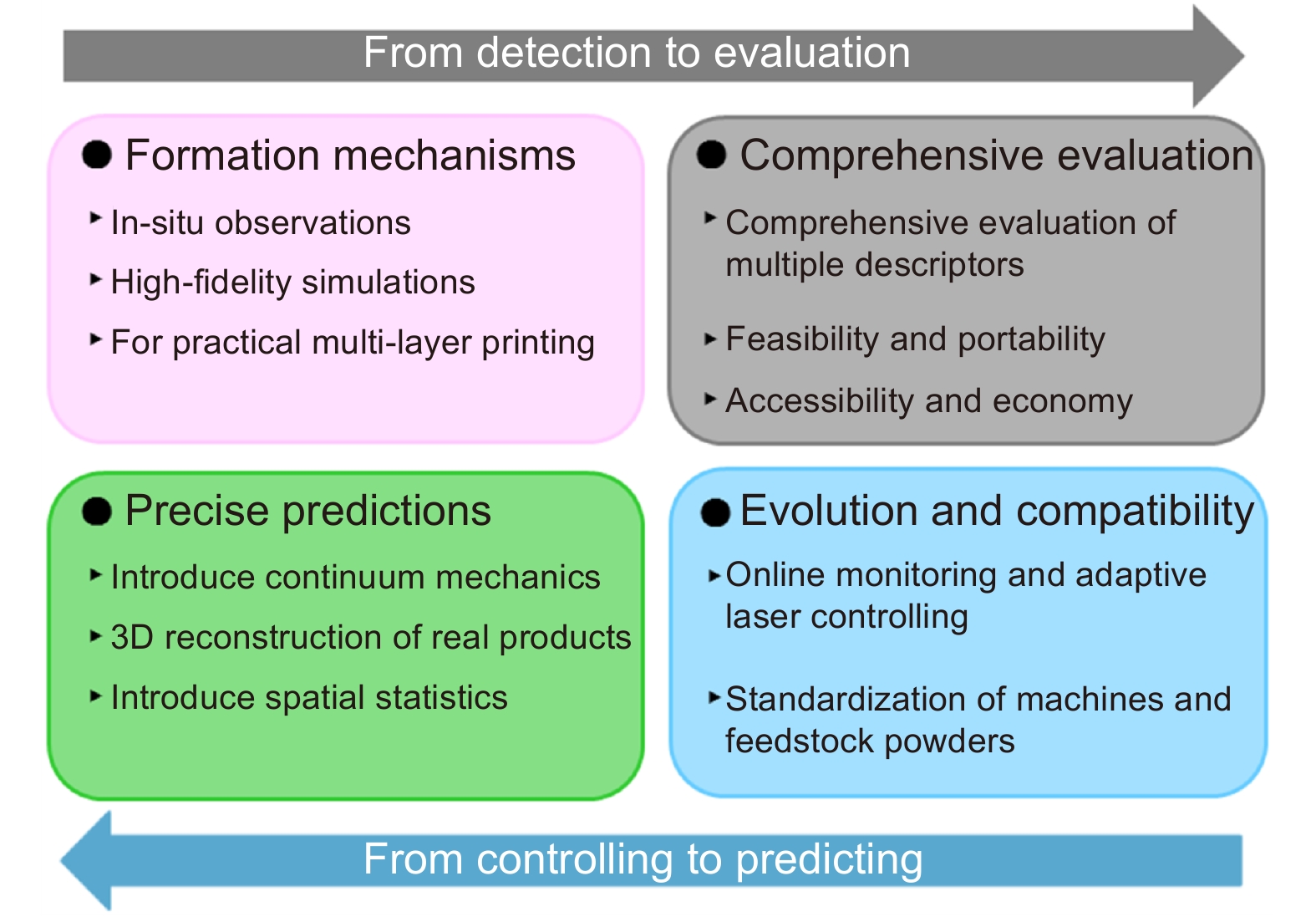

Figure 21.

Challenges and potential opportunities for the study of porosity in LPBF printed metals.

E-mail Alert

E-mail Alert RSS

RSS

DownLoad:

DownLoad: