-

摘要:

水导激光切割技术是一项利用水束导引激光到加工平面的新型切割技术,由于其热影响区小、加工精度高、无污染等优点受到了众多研究者的广泛关注。本文首先阐述了水导激光切割利用激光在空气和水交界面发生全发射的原理及其相对于传统激光切割的优势,其次从理论与工艺两个方面综述了水导激光切割的国内外研究进展,总结了水导激光设备的发展现状,最后针对水导激光切割的技术难点进行分析并且展望了该技术未来发展的趋势

Abstract:Water-jet guided laser cutting technology is a new type of cutting method which utilizes the water jet to guide the laser to the machining plane. It has been widely concerned by many researchers for its superiorities of small heat affected zone, high precision and no pollution. In this paper, the principle of laser total reflection at the interface of air and water used by water-jet guided laser is firstly introduced, and its advantages compared with conventional laser cutting are also expounded. Besides, the domestic and international research progress of water-jet guided laser cutting is reviewed in term of theory and process. The development status of water-jet guided laser equipment is summarized. Finally, the technical difficulties of water-jet guided laser cutting are analyzed, and the future development trend of this technology is expected.

-

Key words:

- water-jet guided laser /

- heat affected zone /

- coupling technology /

- nozzle orifice

-

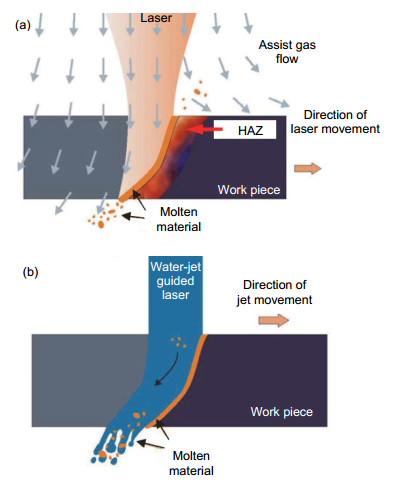

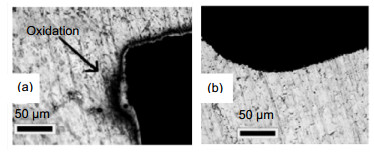

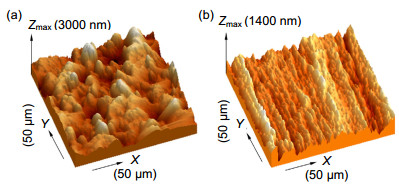

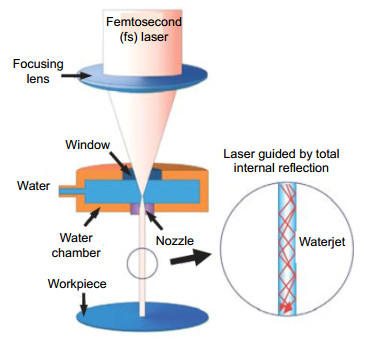

In the field of parts cutting, compared with the traditional mechanical cutting and high-pressure water jet cutting, laser cutting has significant superiorities in processing efficiency, precision and environmental protection. However, the thermal damage on the material caused by laser cutting will affect the performance and working life of the parts which limits the development of laser cutting. In order to solve this problem, water-jet guided laser cutting technology is invented. Water-jet guided laser cutting technology is a composite processing method which uses the water jet to guide the laser beam for cutting the workpiece. For the difference between the refractive indexes of water and air, when the laser beam passes through the water and air interface at a certain angle, the laser will be totally reflected without refraction if the incident angle is less than the total reflection critical angle. This phenomenon can be utilized to propagate the laser in the water jet and guide it to the machined surface for cutting. The advantages of this technology are small heat affected zone, high precision, no pollution and so on. Because of the superiorities of the water-jet guided laser cutting technology, the domestic and international researchers are increasingly interested in the relevant principles and key technology of the water-jet guided laser cutting. Their researches provided theoretical basis of the water-jet guided laser which promotes its development and application. The domestic and international research progress of water-jet guided laser cutting is reviewed from two aspects: theory and process. For example, Li Ling studied the water-jet guided laser technology by the experiment, finding the relationship about the laser energy attenuation and water jet stability. Besides, the cutting parameters about pulse energy, processing speed, and working distance for processing silicon were also optimized. The processed silicon wafer has little burrs, cracks, heat affected zone, and the surface quality is good. At last, the development status of water-jet guided laser equipment is summarized. The future development direction of the water-jet guided laser cutting is larger energy and finer water jet. But at the current stage of research, there are many technical difficulties in terms of nozzle orifice manufacture, coupling control system and process research. In the future, theoretical and experimental researches on water-jet guided laser cutting should be studied to accelerate the development of equipment and reduce the gap between the domestic and abroad.

-

-

-

[1] 周永恒, 廖健宏, 蒙红云, 等.血管内支架的激光精细切割技术[J].应用激光, 2005, 25(3): 161–164. http://www.cqvip.com/QK/90981X/200503/16190032.html

Zhou Yongheng, Liao Jianhong, Meng Hongyun, et al. Laser micro-fabrication of endovascular stent [J]. Applied Laser, 2005, 25(3): 161–164. http://www.cqvip.com/QK/90981X/200503/16190032.html

[2] Sealy M P, Guo Y B, Liu J F, et al. Pulsed laser cutting of magnesium-calcium for biodegradable stents[J]. Procedia CIRP, 2016, 42: 67–72. doi: 10.1016/j.procir.2016.02.190

[3] 苏红新.水导激光加工技术[J].光电子技术与信息, 1998, 11(3): 35–38. https://www.wenkuxiazai.com/doc/1228216cc5da50e2524d7ff5.html

Sun Hongxin. Water-jet guided laser processing technology[J]. Optoelectronic Technology & Informotion, 1998, 11(3): 35–38. https://www.wenkuxiazai.com/doc/1228216cc5da50e2524d7ff5.html

[4] Perrottet D, Housh R, Richerzhagen B, et al. Heat damage-free laser-microjet cutting achieves highest die fracture strength[J]. Proceedings of SPIE, 2005, 5713: 285–293. doi: 10.1117/12.586710

[5] 陈聪, 高明, 顾云泽, 等.光纤激光切割铝合金薄板工艺特性研究[J].中国激光, 2014, 41(6): 603004. http://www.opticsjournal.net/abstract.htm?id=OJ150119000087PlRoUr

Chen Cong, Gao Ming, Gu Yunze, et al. Study on fiber laser cutting of aluminum alloy sheet[J]. Chinese Journal of Lasers, 2014, 41(6): 603004. http://www.opticsjournal.net/abstract.htm?id=OJ150119000087PlRoUr

[6] 汪旭煌, 姚建华, 周国斌, 等.液晶玻璃基板激光切割数值模拟与实验[J].中国激光, 2011, 38(6): 603003. http://www.opticsjournal.net/abstract.htm?aid=OJ120803000846z7C0Fb

Wang Xuhuang, Yao Jianhua, Zhou Guobin, et al. Numerical simulation and experiment of laser cutting liquid crystal display glass substrates[J]. Chinese Journal of Lasers, 2011, 38(6): 603003. http://www.opticsjournal.net/abstract.htm?aid=OJ120803000846z7C0Fb

[7] 王扬, 李春奇, 杨立军, 等.非常规激光加工技术的研究[J].红外与激光工程, 2011, 40(3): 448–454. https://www.researchgate.net/profile/Na_Cai5/publication/284100486_Research_on_Unconventional_Laser_Machining/links/5784616508ae37d3af6c190b.pdf?origin=publication_detail

Wang Yang, Li Chunqi, Yang Lijun, et al. Research on unconventional laser machining[J]. Infrared and Laser Engineering, 2011, 40(3): 448–454. https://www.researchgate.net/profile/Na_Cai5/publication/284100486_Research_on_Unconventional_Laser_Machining/links/5784616508ae37d3af6c190b.pdf?origin=publication_detail

[8] 李灵. 水导激光微细加工技术研究[D]. 哈尔滨: 哈尔滨工业大学, 2008.

Li Ling. Study on water-jet guided laser micromachining tech-nology[D]. Harbin: Harbin Institute of Technology, 2008.

[9] Richerzhagen B. Entwicklung und konstruktion eines systems zur uebertragung von Laserenergie für die Laserzahnbehandlung[D]. Lausanne: EPFL, 1994.

[10] Richerzhagen B, Delacrétaz G P, Salathé R -P. Complete model to simulate the thermal defocusing of a laser beam focused in water[J]. Optical Engineering, 1996, 35(7): 2058–2067. doi: 10.1117/1.600995

[11] Kruusing A. Underwater and water-assisted laser processing: Part 1—general features, steam cleaning and shock processing [J]. Optics and Lasers in Engineering, 2004, 41(2): 307–327. http://citeseerx.ist.psu.edu/viewdoc/summary?doi=10.1.1.473.7057

[12] Kruusing A. Underwater and water-assisted laser processing: Part 2—Etching, cutting and rarely used methods[J]. Optics and Lasers in Engineering, 2004, 41(2): 329–352. https://www.sciencedirect.com/science/article/pii/S0143816602001434

[13] Spiegel Á, Vágó N, Wagner F R. High efficiency Raman scat-tering in micrometer-sized water jets[J]. Optical Engineering, 2004, 43(2): 450–455. doi: 10.1117/1.1634292

[14] 陈笑. 高功率激光与水下物质相互作用过程与机理研究[D]. 南京: 南京理工大学, 2004.

Chen Xiao. Studies on mechanisms of the interaction between high-power laser and matter in water[D]. Nanjing: Nanjing University of Science &Technology, 2004.

[15] Couty P, Wagner F R, Hoffmann P W. Laser coupling with a multimode water-jet waveguide[J]. Optical Engineering, 2005, 44(6): 068001. doi: 10.1117/1.1928280

[16] Fu C H, Guo Y B, Sealy M P. A predictive model and validation of laser cutting of nitinol with a novel moving volumetric pulsed heat flux[J]. Journal of Materials Processing Technology, 2014, 214(12): 2926–2934. doi: 10.1016/j.jmatprotec.2014.06.010

[17] Li C F, Johnson D B, Kovacevic R. Modeling of waterjet guided laser grooving of silicon[J]. International Journal of Machine Tools and Manufacture, 2003, 43(9): 925–936. doi: 10.1016/S0890-6955(03)00063-4

[18] Yang Lijun, Wang M L, Wang Yang, et al. Numerical simulation on the temperature field of water-jet guided laser micromachining[J]. Advanced Materials Research, 2009, 69–70: 333–337. doi: 10.4028/www.scientific.net/AMR.69-70

[19] Yang Lijun, Wang Maolu, Wang Yang, et al. Numerical and experimental research on water-jet guided laser micromachin-ing[J]. Materials Science Forum, 2009, 626–627: 297–302. doi: 10.4028/www.scientific.net/MSF.626-627

[20] Wang Yang, Li Ling, Yang Lijun, et al. Simulation and experimental research on water-jet guided laser cutting silicon wafer[C]// International Conference on Electronic Packaging Technology & High Density Packaging, 2008. Shanghai, China, 2008: 1–6.

[21] 詹才娟, 李昌烽, 潘永琛, 等.微水射流导引激光精密打孔过程的流动分析[J].力学季刊, 2011, 32(2): 159–165. http://industry.wanfangdata.com.cn/dl/Detail/Thesis?id=Thesis_Y1604169

Zhan Caijuan, Li Changfeng, Pan Yongchen, et al. Analysis of fluid flow in micro-waterjet guided laser precision drilling pro-cess[J]. Chinese Quarterly of Mechanics, 2011, 32(2): 159–165. http://industry.wanfangdata.com.cn/dl/Detail/Thesis?id=Thesis_Y1604169

[22] 詹才娟, 李昌烽, 王瑞, 等.微水射流导引激光打孔的传热分析[J].工程热物理学报, 2011, 32(1): 111–114. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y1604169

Zhan Caijuan, Li Changfeng, Wang Rui, et al. Analyses of heat transfer in micro-waterjet guided laser drilling process[J]. Journal of Engineering Thermophysics, 2011, 32(1): 111–114. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y1604169

[23] Wagner F R, Boillat C, Buchilly J M, et al. High-speed cutting of thin materials with a Q-switched laser in a water-jet versus conventional laser cutting with a free running laser[J]. Proceedings of SPIE, 2003, 4977: 70–75. doi: 10.1117/12.479228

[24] Rashed C A A, Romoli L, Tantussi F, et al. Water jet guided laser as an alternative to EDM for micro-drilling of fuel injector nozzles: A comparison of machined surfaces[J]. Journal of Manufacturing Processes, 2013, 15(4): 524–532. doi: 10.1016/j.jmapro.2013.08.002

[25] Li Ling, Wang Yang, Yang Lijun, et al. Experimental research on water-jet guided laser processing[J]. Proceedings of SPIE, 2007, 6595: 659525. https://www.spiedigitallibrary.org/conference-proceedings-of-spie/6595/1/Experimental-research-on-water-jet-guided-laser-processing/10.1117/12.726482.pdf

[26] Weiss L, Aillerie M, Tazibt A, et al. Surface oxidation and phase transformation of the stainless steel by hybrid laser-waterjet impact[J]. Materials Research Express, 2014, 1(3): 036501. doi: 10.1088/2053-1591/1/3/036501

[27] Adelmann B, Ngo C, Hellmann R. High aspect ratio cutting of metals using water jet guided laser[J]. The International Journal of Advanced Manufacturing Technology, 2015, 80(9–12): 2053–2060. doi: 10.1007/s00170-015-7161-8

[28] Ng E Y -K, Guannan D. The stability of 30-μm-diameter water jet for jet-guided laser machining[J]. The International Journal of Advanced Manufacturing Technology, 2015, 78(5–8): 939–946. doi: 10.1007/s00170-014-6692-8

[29] Li Chunqi, Yang Lijun, Wang Yang. Experimental study on water-jet guided laser machining magnesium alloy[J]. Materials Science Forum, 2012, 723: 476–480. doi: 10.4028/www.scientific.net/MSF.723

[30] Li Chunqi, Yang Lijun, Wang Yang. A research on surface morphology of cutting of titanium sheet with water-jet guided laser and conventional laser[J]. Applied Mechanics & Materials, 2012, 120: 366–370. https://www.scientific.net/AMM.120.366

[31] Li Chunqi, Yang Lijun, Wang Yang. Investigation on water-jet guided laser cutting of titanium alloy thin sheets[J]. Energy Education Science and Technology Part A: Energy Science and Research, 2012, 30(1): 481–488. https://www.researchgate.net/publication/288284916_Investigation_on_water-jet_guided_laser_cutting_of_titanium_alloy_thin_sheets

[32] Kray D, Hopman S, Spiegel A, et al. Study on the edge isolation of industrial silicon solar cells with waterjet-guided laser[J]. Solar Energy Materials and Solar Cells, 2007, 91(17): 1638–1644. doi: 10.1016/j.solmat.2007.05.028

[33] Porter J A, Louhisalmi Y A, Karjalainen J A, et al. Cutting thin sheet metal with a water jet guided laser using various cutting distances, feed speeds and angles of incidence[J]. International Journal of Advanced Manufacturing Technology, 2007, 33(9–10): 961–967. doi: 10.1007/s00170-006-0521-7

[34] Mai T A, Richerzhagen B, Snowdon P C, et al. The Laser MicroJet (LMJ): a multi-solution technology for high quality mi-cro-machining[J]. Proceedings of SPIE, 2007, 6459: 64590P. doi: 10.1117/12.701070

[35] Brecher C, Janssen H, Eckert M, et al. Thermal investigation of interaction between high-power CW-laser radiation and a wa-ter-jet[J]. Physics Procedia, 2016, 83: 317–327. doi: 10.1016/j.phpro.2016.08.033

[36] Chida I, Shiihara K, Nomura K, et al. Decreasing Waste of Laser Cutting by Metal Fume Capturing With Water[C]// American Society of Mechanical Engineers. 2014 22nd International Conference on Nuclear Engineering, 2014: V004T08A004-V004T08A004.

[37] Synova. The products of LCS 300[EB/OL]. https://www.synova.ch/products/tool-cutting-systems/item/64-lcs-300. html.

[38] 李灵, 杨立军, 王扬, 等.水导激光微细加工中激光与水束光纤耦合技术[J].光学精密工程, 2008, 16(9): 1614–1621. http://www.eope.net/fileup/PDF/2008-0370.pdf

Li Ling, Yang Lijun, Wang Yang, et al. Laser and water-jet fiber coupling technology for water-jet guided laser micromachining[J]. Optics and Precision Engineering, 2008, 16(9): 1614–1621. http://www.eope.net/fileup/PDF/2008-0370.pdf

[39] 叶瑞芳, 沈阳, 王磊, 等.新型水导引激光耦合系统研究[J].厦门大学学报(自然版), 2009, 48(3): 369–372. http://dspace.xmu.edu.cn/handle/2288/105203?locale-attribute=zh

Ye Ruifang, Shen Yang, Wang Lei, et al. Novel coupling system of water-jet guided laser[J]. Journal of Xiamen University (Natural Science), 2009, 48(3): 369–372. http://dspace.xmu.edu.cn/handle/2288/105203?locale-attribute=zh

[40] Li Meng, Zhang Wenwu, Zhang Xiping, et al. A simple optical coupling method for water-jet guided laser machining system[J]. Applied Mechanics and Materials, 2014, 541–542: 774–779. doi: 10.4028/www.scientific.net/AMM.541-542

[41] 杨保健, 谢顺德, 代福.微水导激光切割玻璃的耦合装置设计[J].激光技术, 2017, 41(2): 247–250. doi: 10.7510/jgjs.issn.1001-3806.2017.02.020

Yang Baojian, Xie Shunde, Dai Fu. Design of coupling device for laser cutting guided by water beam[J]. Laser Technology, 2017, 41(2): 247–250. doi: 10.7510/jgjs.issn.1001-3806.2017.02.020

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: