| Citation: | Zhou R, Lin S D, Ding Y, Yang H, Ong Y K K et al. Enhancement of laser ablation via interacting spatial double-pulse effect. Opto-Electron Adv 1, 180014 (2018). doi: 10.29026/oea.2018.180014 |

Original Article Open Access

Enhancement of laser ablation via interacting spatial double-pulse effect

-

Abstract

A novel spatial double-pulse laser ablation scheme is investigated to enhance the processing quality and efficiency for nanosecond laser ablation of silicon substrate. During the double-pulse laser ablation, two splitted laser beams simultaneously irradiate on silicon surface at a tunable gap. The ablation quality and efficiency are evaluated by both scanning electron microscope and laser scanning confocal microscope. As tuning the gap distance, the ablation can be significantly enhanced if the spatial interaction between the two splitted laser pulses is optimized. The underlying physical mechanism for the interacting spatial double-pulse enhancement effect is attributed to the redistribution of the integrated energy field, corresponding to the temperature field. This new method has great potential applications in laser micromachining of functional devices at higher processing quality and faster speed.-

Keywords:

- double-pulse /

- laser ablation /

- efficiency /

- quality

-

-

References

[1] Choudhury I A, Shirley S. Laser cutting of polymeric materials: an experimental investigation. Opt Laser Technol 42, 503-508 (2010). doi: 10.1016/j.optlastec.2009.09.006 [2] Ancona A, Döring S, Jauregui C, Röser F, Limpert J et al. Femtosecond and picosecond laser drilling of metals at high repetition rates and average powers. Opt Lett 34, 3304-3306 (2009). doi: 10.1364/OL.34.003304 [3] Miyamoto I, Cvecek K, Okamoto Y, Schmidt M. Internal modification of glass by ultrashort laser pulse and its application to microwelding. Appl Phys A 114, 187-208 (2014). doi: 10.1007/s00339-013-8115-3 [4] Lee Y J, Kuo H C, Lu T C, Wang S C, Ng K W et al. Study of GaN-based light-emitting diodes grown on chemical wet-etching-patterned sapphire substrate with V-shaped pits roughening surfaces. J Lightwave Technol 26, 1455-1463 (2008). doi: 10.1109/JLT.2008.922151 [5] Hyypio D. Mitigation of bearing electro-erosion of inverter-fed motors through passive common-mode voltage suppression. IEEE Trans Ind Appl 41, 576-583 (2005). doi: 10.1109/TIA.2005.844373 [6] Meng H Y, Liao J H, Zhou Y H, Zhang Q M. Laser micro-processing of cardiovascular stent with fiber laser cutting system. Opt Laser Technol 41, 300-302 (2009). doi: 10.1016/j.optlastec.2008.06.001 [7] Watanabe W, Li Y, Itoh K. Ultrafast laser micro-processing of transparent material. Opt Laser Technol 78, 52-61 (2016). doi: 10.1016/j.optlastec.2015.09.023 [8] Rizvi N H, Apte P. Developments in laser micro-machining techniques. J Mater Process Technol 127, 206-210 (2002). doi: 10.1016/S0924-0136(02)00143-7 [9] Lu B H, Lan H B, Liu H Z. Additive manufacturing frontier: 3D printing electronics. Opto-Electron Adv 1, 170004 (2018). [10] Xu K C, Zhang C T, Zhou R, Ji R, Hong M H. Hybrid micro/nano-structure formation by angular laser texturing of Si surface for surface enhanced Raman scattering. Opt Express 24, 10352-10358 (2016). doi: 10.1364/OE.24.010352 [11] Mahdieh M H, Nikbakht M, Eghlimi Moghadam Z, Sobhani M. Crater geometry characterization of Al targets irradiated by single pulse and pulse trains of Nd:YAG laser in ambient air and water. Appl Surf Sci 256, 1778-1783 (2010). doi: 10.1016/j.apsusc.2009.10.003 [12] König J, Nolte S, Tünnermann A. Plasma evolution during metal ablation with ultrashort laser pulses. Opt Express 13, 10597-10607 (2005). doi: 10.1364/OPEX.13.010597 [13] Crawford T H R, Borowiec A, Haugen H K. Femtosecond laser micromachining of grooves in silicon with 800 nm pulses. Appl Phys A 80, 1717-1724 (2005). doi: 10.1007/s00339-004-2941-2 [14] Bulgakova N M, Bulgakov A V. Pulsed laser ablation of solids: transition from normal vaporization to phase explosion. Appl Phys A 73, 199-208 (2001). doi: 10.1007/s003390000686 [15] Zhou M, Zhang Y K, Cai L. Laser shock forming on coated metal sheets characterized by ultrahigh-strain-rate plastic deformation. J Appl Phys 91, 5501-5503 (2002). doi: 10.1063/1.1459624 [16] Gerhard C, Roux S, Brückner S, Wieneke S, Viöl W. Atmospheric pressure argon plasma-assisted enhancement of laser ablation of aluminum. Appl Phys A 108, 107-112 (2012). doi: 10.1007/s00339-012-6942-2 [17] Kajita S, Ohno N, Takamura S, Sakaguchi W, Nishijima D. Plasma-assisted laser ablation of tungsten: reduction in ablation power threshold due to bursting of holes/bubbles. Appl Phys Lett 91, 261501 (2007). doi: 10.1063/1.2824873 [18] Babushok V I, DeLucia Jr F C, Gottfried J L, Munson C A, Miziolek A W. Double pulse laser ablation and plasma: laser induced breakdown spectroscopy signal enhancement. Spectrochim Acta Part B: At Spectrosc 61, 999-1014 (2006). doi: 10.1016/j.sab.2006.09.003 [19] Jansen E D, Asshauer T, Frenz M, Motamedi M, Delacrétaz G et al. Effect of pulse duration on bubble formation and laser-induced pressure waves during holmium laser ablation. Lasers Surg Med 18, 278-293 (1996). doi: 10.1002/(ISSN)1096-9101 -

Supplementary Information

Supplementary information for Enhancement of laser ablation via interacting spatial double-pulse effect

-

Access History

Article Metrics

-

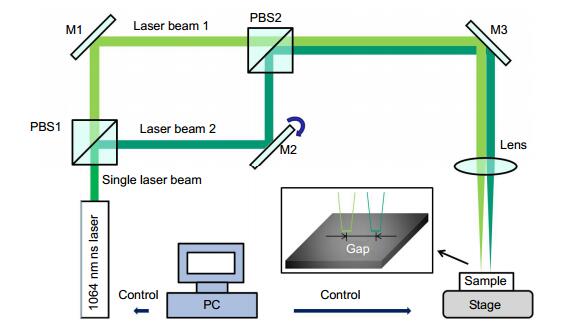

Figure 1.

Schematic diagram of the experimental setup for the spatial double-pulse laser ablation.

-

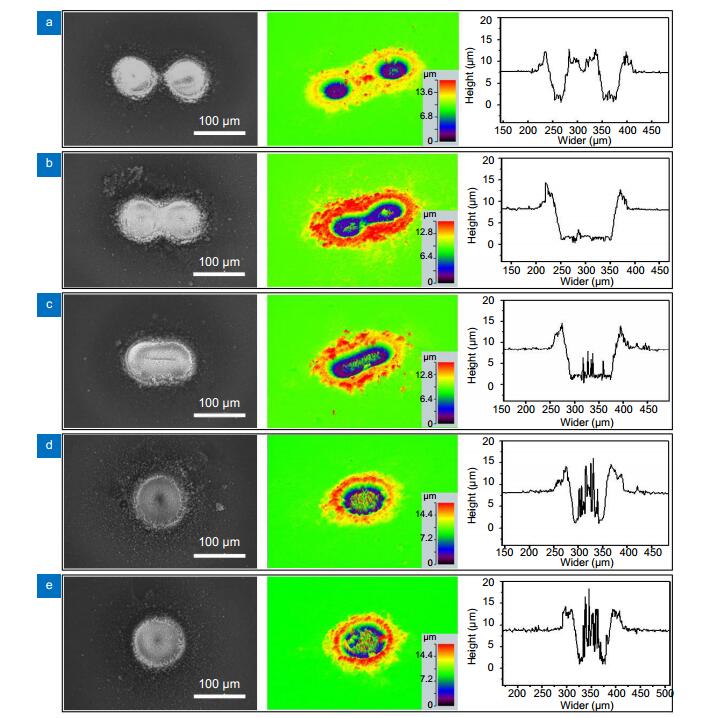

Figure 2.

SEM images, 3D reconstructions and 2D profiles of craters created by the splitted double-pulse laser beams at different gaps of (a) 100 μm, (b) 80 μm, (c) 60 μm, (d) 0 μm, and (e) by single laser beam at a total laser power of 10 W.

-

Figure 3.

SEM images of (a) two intersecting grooves processed by double laser pulses and (b) zoom-in state.

-

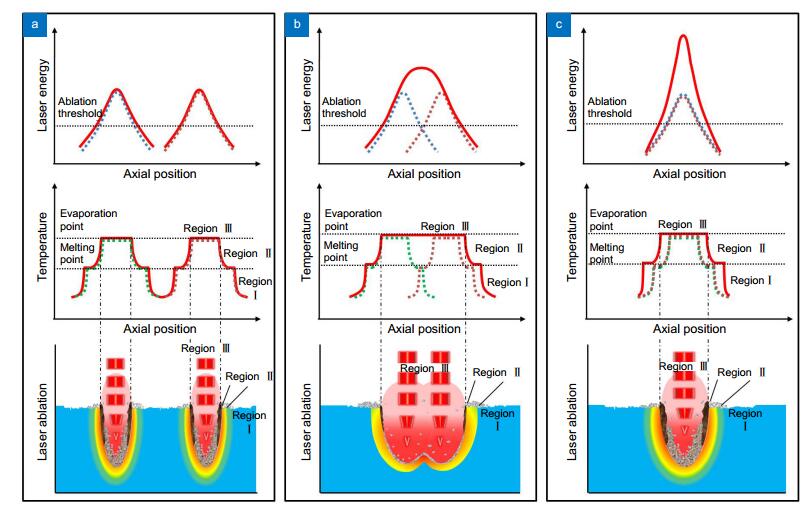

Figure 4.

The schematic diagram of distributions of energy field (upper), temperature field (middle) and the interaction between laser and silicon (bottom) at different gaps.

E-mail Alert

E-mail Alert RSS

RSS

DownLoad:

DownLoad: