-

摘要:

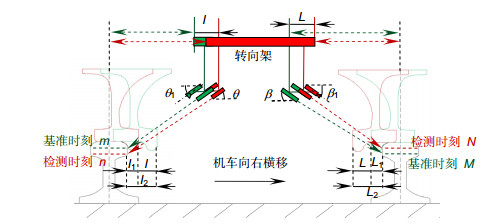

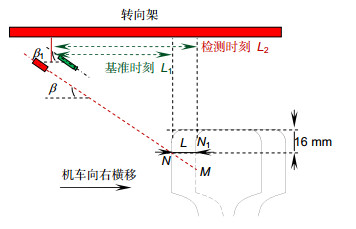

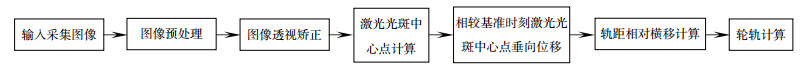

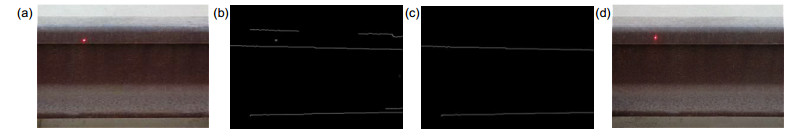

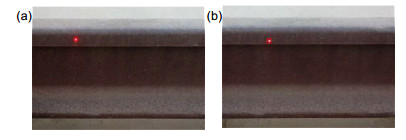

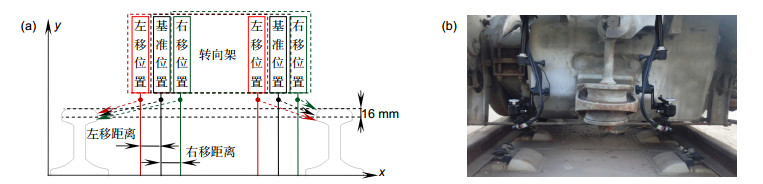

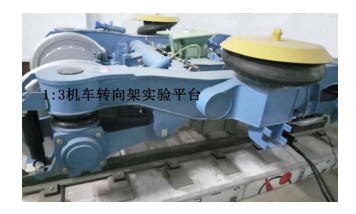

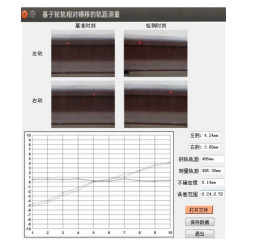

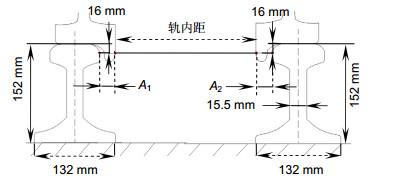

针对传统轨距检测方法设备复杂、安装要求高和数据计算量大的问题,设计了一种基于轮轨相对横移的轨距检测系统。该系统首先使用两组激光源与相机组合分别采集左右两边轨头内侧激光光斑图像,然后根据钢轨边缘特点使用Hough检测与透视变换将其矫正为同一采集距离正视视角图像,接着对比基准时刻图像计算激光光斑中心点垂向位移变化量并通过其与轮对横向相对位移的几何关系分别计算两侧轮轨相对横移变化量,最后由两者差值得到相对初始时刻轨距变化量实现轨距的间接检测。实验结果表明,该轨距检测方法硬件结构简单,数据计算量小且检测精度较高,可实现轨距参数的非接触式检测。

Abstract:

Abstract:Aiming at the complexity of the traditional gauge detection method, high requirements for the installation and large amount of data analysis, a gauge measurement method based on the relative transverse movement of wheel and rail is designed in this paper. Two sets of laser source and camera combinations are used to dynamically collect the image of the inner straight line part of the rail head in the method. According to the rail parameters, the Hough detection and perspective transformation are used to rectify the image from the same acquisition distance. Compared to datum moment, the variation of vertical displacement of the center point of the laser is computed. And through the geometrical relation of the variation previously described and the lateral relative displacements of the two wheels, the relative transverse displacement of the two wheels is calculated. The relative initial time gauge change is gained by the difference, which realizes the indirect measurement of the track gauge. The experimental results show that the method has the characteristics of simple hardware structure, small data calculation, high measurement precision, and can realize non-contact dynamic measurement of gauge parameters.

-

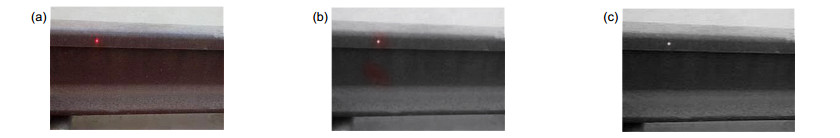

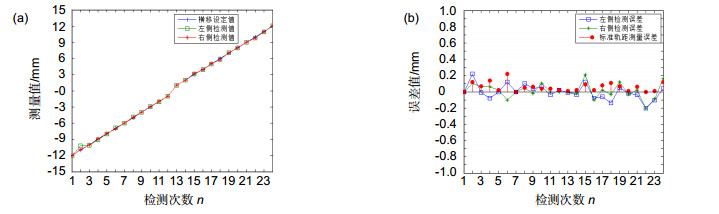

Overview: With the rapid development of urban rail transit, the detection of track infrastructure is an important guarantee for ensuring the safe operation of trains. Gauge is one of the most important parameters in the track infrastructure. The change of the gauge distance will cause various vibrations of the train to change the wheel-rail force. It is the control factor that affects the safety and stability of the train operation, and is also an important reason for the damage and failure of the track structural components. With the increase of the operation speed of high-speed railways and the expansion of operation scale, it is an important task in rail transit safety work to master the information of gauge status and ensure the safety of rail transit transportation. However, most of the current gauge detection methods have problems such as high installation difficulty, large amount of data calculation, and expensive detection, and is difficult to achieve ideal effect in complicated dynamic environments. Therefore, this paper proposes a gauge detection method based on the relative movement of wheel and rail. This method uses the lateral variation of the left and right wheel pairs relative to the reference point to measure the gauge distance indirectly during the locomotive operation. Firstly, two laser cameras are used to respectively collect the laser spot image projected by the laser source into the left and right gauge detection area, and then the perspective correction transformation matrix is obtained through coordinate transformation according to the positional relationship of the corresponding feature points in the reference time image and the detection time image and through the transformation matrix. The detection time image is corrected to obtain a front view image which is unified with the acquisition time at the reference time. The horizontal swing during the locomotive operation is much larger than the vertical vibration. Therefore, we accurately extract and locate the center point position of the laser spot. The mathematical transformation is established by the vertical displacement change of the laser spot center point in the two-track gauge detection area. The change of the relative movement between the wheel and rail on both sides of the reference time is obtained by calculation, and the gauge detection is finally realized. We verified and evaluated the gauge detection method proposed in this paper through multiple sets of dynamic experiments and using a variety of evaluation indicators. The experimental results show that the maximum error of the gauge detection method is less than 1 mm, which can meet the requirements of high-speed track detection as stipulated by China Railway Corporation. The detection device composed of simple structures is easy to install. In addition, the device has high robustness to a complex environment, and has certain practicability.

-

-

表 1 标准轨距横移误差分析数据分析

Table 1. Data analysis of standard gauge cross movement error analysis

mm 平均值 方差 标准差 A类不确定度(贝塞尔) 左侧横移检测误差 0.06617 0.00345 0.05878 0.01226 右侧横移检测误差 0.062917 0.00378 0.06147 0.01282 标准轨距检测误差 0.057417 0.00285 0.05336 0.01113 表 2 轨距检测数据分析

Table 2. Gauge inspection data analysis

mm 检测次数 设定轨距 检测均值 检测误差 总不确定度(ρ=0.95)[18] 误差范围 10 474 474.47 0.47 0.16 0.54~0.86 10 477 477.62 0.62 0.15 0.47~0.77 10 480 480.67 0.67 0.18 0.49~0.95 10 483 483.65 0.65 0.14 0.51~0.79 10 486 486.68 0.68 0.17 0.51~0.95 -

[1] 中国铁路总公司.铁路技术管理规程[R].北京: 中国铁路总公司, 2014: 12-13.

China Railway Corporation. Regulations on railway technical management[R]. Beijing: China Railway Corporation, 2014: 12-13.

[2] 冯青松, 雷晓燕, 练松良.不平顺条件下高速铁路轨道振动的解析研究[J].振动工程学报, 2008, 21(6): 559-564. doi: 10.3969/j.issn.1004-4523.2008.06.005

Feng Q S, Lei X Y, Lian S L. Vibration analysis of high-speed railway tracks with geometric irregularities[J]. Journal of Vibration Engineering, 2008, 21(6): 559-564. doi: 10.3969/j.issn.1004-4523.2008.06.005

[3] Lei Y, Tian X Y, Qi F L, et al. Vertical track irregularity influence on the wheel high-frequency vibration in wheel-rail system[J]. Mathematical Problems in Engineering, 2016, 2016: 5082319. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=Doaj000004702322

[4] 罗世辉.轨距对机车车辆稳定性影响的研究[J].中国铁道科学, 2010, 31(2): 56-60. http://d.old.wanfangdata.com.cn/Periodical/zgtdkx201002011

Luo S H. Study on the influence of the track gauge on vehicle yaw stability[J]. China Railway Science, 2010, 31(2): 56-60. http://d.old.wanfangdata.com.cn/Periodical/zgtdkx201002011

[5] Perrin G, Duhamel D, Soize C, et al. Quantification of the influence of the track geometry variability on the train dynamics[J]. Mechanical Systems and Signal Processing, 2015, 60-61: 945-957. doi: 10.1016/j.ymssp.2015.01.004

[6] Shah M. Automated visual inspection/detection of railroad track[R]. Orlando: University of Central Florida, 2010.

[7] 史红梅, 张继科.基于激光三角测量原理的轨距检测系统研究[J].仪器仪表学报, 2013, 34(9): 1934-1940. http://d.old.wanfangdata.com.cn/Periodical/yqyb201309003

Shi H M, Zhang J K. Study on track gauge measurement system based on laser triangulation principle[J]. Chinese Journal of Scientific Instrument, 2013, 34(9): 1934-1940. http://d.old.wanfangdata.com.cn/Periodical/yqyb201309003

[8] 闵永智, 王红霞, 康飞, 等.基于图像式传感器的铁路轨距检测系统研究[J].激光技术, 2015, 39(3): 344-348. http://d.old.wanfangdata.com.cn/Periodical/jgjs201503014

Min Y Z, Wang H X, Kang F, et al. Study on rail gauge detection systems based on image sensors[J]. Laser Technology, 2015, 39(3): 344-348. http://d.old.wanfangdata.com.cn/Periodical/jgjs201503014

[9] 魏世斌, 刘伶萍, 赵延峰, 等. GJ-6型轨道检测系统[J].铁道建筑, 2011(11): 98-101. http://d.old.wanfangdata.com.cn/Periodical/tdjz201111031

Wei S B, Liu L P, Zhao Y F, et al. GJ-6 type track inspection system[J]. Railway Engineering, 2011(11): 98-101. http://d.old.wanfangdata.com.cn/Periodical/tdjz201111031

[10] 代勤, 王延杰, 韩广良.基于改进Hough变换和透视变换的透视图像矫正[J].液晶与显示, 2012, 27(4): 552-556. http://d.old.wanfangdata.com.cn/Periodical/yjyxs201204022

Dai Q, Wang Y J, Han G L. Perspective image rectification based on improved hough transformation and perspective transformation[J]. Chinese Journal of Liquid Crystals and Displays, 2012, 27(4): 552-556. http://d.old.wanfangdata.com.cn/Periodical/yjyxs201204022

[11] 晁志超, 伏思华, 姜广文, 等.单目摄像机-激光测距传感器位姿测量系统[J].光学学报, 2011, 31(3): 0312001. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201103015

Chao Z C, Fu S H, Jiang G W, et al. Mono camera and laser rangefinding sensor position-pose measurement system[J]. Acta Optica Sinica, 2011, 31(3): 0312001. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201103015

[12] 柴东明, 徐旭宇, 刘伶萍, 等. GJ-4型轨检车的检测系统(连载之一)[J].铁道建筑, 2000(2): 36-38. doi: 10.3969/j.issn.1003-1995.2000.02.015

Chai D M, Xu X Y, Liu L P, et al. Detection system of GJ-4 type track inspection vehicle (Part 1)[J]. Railway Engineering, 2000(2): 36-38. doi: 10.3969/j.issn.1003-1995.2000.02.015

[13] Zhang Z F, Feng Q B, Gao Z, et al. A new laser displacement sensor based on triangulation for gauge real-time measurement[J]. Optics & Laser Technology, 2008, 40(2): 252-255. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=b91ca909cfde6e92b1a202242f498929

[14] 徐浩, 王平, 陈嵘, 等.线路条件对高速列车横向动态偏移量的影响[J].铁道科学与工程学报, 2013, 10(5): 12-17. doi: 10.3969/j.issn.1672-7029.2013.05.003

Xu H, Wang P, Chen R, et al. Impact of line condition on transverse dynamic offset of high-speed train[J]. Journal of Railway Science and Engineering, 2013, 10(5): 12-17. doi: 10.3969/j.issn.1672-7029.2013.05.003

[15] 袁小翠, 吴禄慎, 陈华伟.钢轨表面缺陷检测的图像预处理改进算法[J].计算机辅助设计与图形学学报, 2014, 26(5): 800-805. http://d.old.wanfangdata.com.cn/Periodical/jsjfzsjytxxxb201405017

Yuan X C, Wu L S, Chen H W. Improved image preprocessing algorithm for rail surface defects detection[J]. Journal of Computer-Aided Design & Computer Graphics, 2014, 26(5): 800-805. http://d.old.wanfangdata.com.cn/Periodical/jsjfzsjytxxxb201405017

[16] 王彩芸, 王文健, 郭俊, 等.横移量、摇头角对轮轨滚动接触行为的影响研究[J].机械设计与制造, 2012(12): 31-33. http://d.old.wanfangdata.com.cn/Periodical/jxsjyzz201212011

Wang C Y, Wang W J, Guo J, et al. Effects of travers and yaw angel on rolling contact of wheel/rail[J]. Machinery Design & Manufacture, 2012(12): 31-33. http://d.old.wanfangdata.com.cn/Periodical/jxsjyzz201212011

[17] 马增强, 宋子彬, 王永胜.基于激光线的轮轨冲角检测新方法[J].光电工程, 2017, 44(8): 818-825. doi: 10.3969/j.issn.1003-501X.2017.08.009

Ma Z Q, Song Z B, Wang Y S. A method for detecting the wheel rail attack angle based on laser line detection[J]. Opto-Electronic Engineering, 2017, 44(8): 818-825. doi: 10.3969/j.issn.1003-501X.2017.08.009

[18] 夏晶, 孙继银.基于区域生长的前视红外图像分割方法[J].激光与红外, 2011, 41(1): 107-111. doi: 10.3969/j.issn.1001-5078.2011.01.022

Xia J, Sun J G. Forward-looking infrared image segmentation based on region growing[J]. Laser & Infrared, 2011, 41(1): 107-111. doi: 10.3969/j.issn.1001-5078.2011.01.022

[19] 唐冠群.几种激光光斑中心定位算法的比较[J].北京机械工业学院学报, 2009, 24(1): 61-64. doi: 10.3969/j.issn.1674-6864.2009.01.016

Tang G Q. Analysis and comparison of several calculation methods of beam spot center[J]. Journal of Beijing Institute of Machinery, 2009, 24(1): 61-64. doi: 10.3969/j.issn.1674-6864.2009.01.016

[20] 臧慕文.分析测试不确定度的评定与表示(Ⅰ)[J].分析试验室, 2005, 24(11): 74-79. doi: 10.3969/j.issn.1000-0720.2005.11.021

Zang M W. Evaluation and expression of uncertainty for chemical analysis and measurement (Ⅰ)[J]. Chinese Journal of Analysis Laboratory, 2005, 24(11): 74-79. doi: 10.3969/j.issn.1000-0720.2005.11.021

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: