Research on defect inspection method of pipeline robot based on adaptive image enhancement

-

摘要:

针对管道检测过程中图像采集光照不均匀、缺陷边缘提取不准确的问题, 提出一种基于自适应图像增强的管道机器人缺陷检测方法。首先设计单尺度Retinex自适应图像增强算法, 利用引导滤波对图像进行照度分量估计, 经自适应Gamma矫正得到光照均衡图像, 实现自适应图像增强;再对传统Canny边缘检测方法进行改进, 采用双边滤波平滑图像, 通过迭代阈值法进行缺陷图像分割, 根据边缘像素相似性进行连接, 实现缺陷轮廓的有效提取。搭建基于自适应图像增强的管道机器人缺陷检测系统, 利用履带式小车搭载云台摄像机, 对管道内壁缺陷进行全方位视觉检测。实验结果表明, 本文的检测方法可自适应矫正图像亮度, 图像亮度不均匀明显改善, 相比次优算法, 图像信息熵提升2.4%, 图像平均梯度提升2.3%, 峰值信噪比提升4.4%, 可有效提取出管道缺陷边缘, 缺陷识别准确率达到97%。

Abstract:

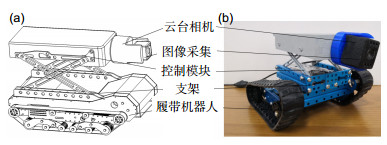

Abstract:In view of the problem about uneven image acquisition and inaccurate edge extraction in pipeline detection process, a pipeline robot defect inspection method based on adaptive image enhancement is proposed. Firstly, a single-scale Retinex adaptive image enhancement algorithm is designed, which uses the guided filter to estimate the illumination component of the Value component of the image, and gets the illumination equilibrium image by adaptive Gamma correction, so as to realize the image enhancement. Then, the traditional Canny edge detection method is improved, using bilateral filtering to smooth the image. Besides, the defect images are segmented by the iterative threshold method, and the edge connection is carried out according to the edge pixel similarity. Therefore, the defect contour of the pipe-wall is extracted effectively. Thirdly, a pipeline robot defect detection system based on adaptive image enhancement is built, and a crawler car equipped with the pan-tilt-zoom camera conducts all-round visual inspection of the defects in the pipeline inner wall. The experimental results show that the detection method in this paper can adaptively correct the image brightness, and the uneven brightness of the image is significantly improved. Compared with the sub-optimal algorithm, the information entropy of the image is increased by 2.4%, the average gradient of the image is increased by 2.3%, and the peak signal to noise ratio is increased by 4.4%, and the pipeline defect edges are extracted effectively with the detection accuracy up to 97%.

-

Key words:

- pipeline robot /

- adaptive image enhancement /

- Gamma correction /

- defect inspection

-

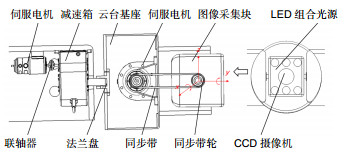

Overview: Digital image processing technology is widely used in the regular detection and maintenance of damaged, aged, faulted pipeline, on account of the virtue of high efficiency, accurate identification, non-contact detection, etc. Aiming at the problem of uneven image acquisition and inaccurate edge extraction in closed pipeline detection process, a pipeline robot defect detection system based on adaptive image enhancement is designed with the pan-tilt-zoom camera as the image acquisition module, Raspberry PI as the image processing system and Arduino as the driving control module to carry on the omni-directional visual inspection to the pipeline inner wall.

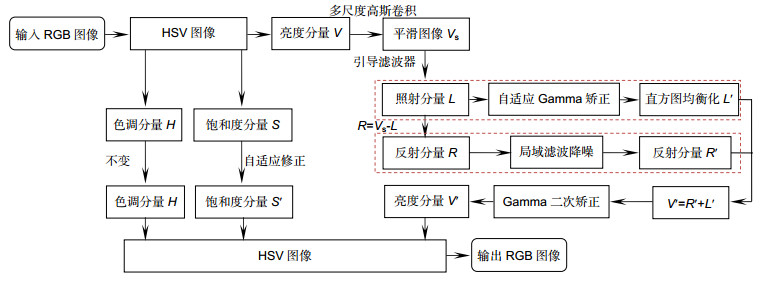

A single-scale Retinex adaptive image enhancement algorithm based on guided filtering is proposed. According to the single-scale Retinex theory, the low frequency irradiation component and the high frequency reflection component can be effectively separated from the Value component of HSV space (converted form RGB images) by using the guided filter. The local filter is used to reduce the noise of the reflection component which is mostly distributed in the high frequency part, and the irradiation component is corrected by the adaptive Gamma algorithm. Finally, the integrated restoration of the corrected RGB image of pipeline defect is realized, and the adaptive image enhancement is achieved.

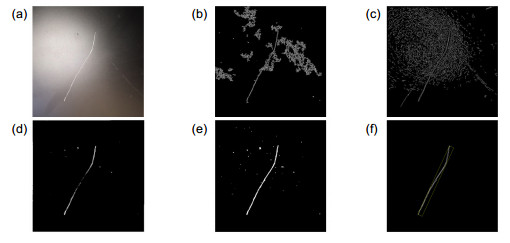

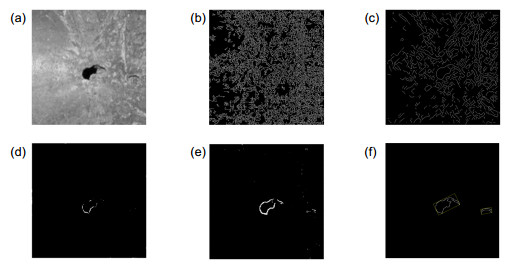

In order to solve the problem of edge blur and threshold setting in traditional Canny detection, bilateral filtering is used to smooth the image and maintain the image edge information effectively. The gradient amplitude is calculated in multiple directions for non-maximum suppression, the adaptive optimal threshold is obtained by iterative threshold method, and the threshold segmentation of the image is carried out. Finally, the edge connection is carried out according to the similarity of edge pixels to realize the accurate extraction of pipeline defect edges.

The experimental results show that the detection system can adapt to correct the image brightness, the uneven illumination of the acquired images is improved obviously. Compared with the suboptimal algorithm, the information entropy of the defect image increases by 2.4%, the average gradient increases by 2.3%, the peak signal to noise ratio increases by 4.4%, and the improved Canny detection algorithm can extract the edge of pipeline defects effectively with the detection accuracy up to 97%. In this paper, the defect detection system of pipeline robot based on adaptive image enhancement can be used to detect and identify pipeline defects in closed pipeline under uneven illumination environment with high detection accuracy, compact structure and strong applicability.

-

-

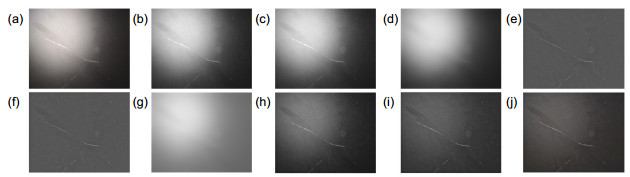

图 5 算法处理流程图。(a)原始图像;(b)亮度分量;(c)平滑图像;(d)照射分量;(e)反射分量;(f)照射分量局域滤波;(g)照射分量Gamma矫正;(h)矫正后的亮度图;(i)二次Gamma矫正后的亮度图;(j)图像增强结果

Figure 5. Processing flow chart of the proposed algorithm. (a) Original image; (b) Luminance component; (c) Smooth image; (d) Illumination component; (e) Reflection component; (f) Local filtering of Illumination component; (g) Gamma correction of Illumination component; (h) Corrected luminance component; (i) Luminance component after secondary Gamma correction; (j) Adaptive enhancement result

图 6 不同图像增强算法处理结果对比。(a)原始图像;(b) MSR处理结果图;(c)直方图均衡化处理结果;(d) SVLM处理结果图;(e)局部均方差处理结果;(f)同态滤波处理结果;(g)本文处理结果

Figure 6. Comparison of different image enhancement processing methods. (a) Original image; (b) Enhanced image of MSR; (c) Enhanced image of histogram equalization; (d) Enhanced image of SVLM; (e) Enhanced image of local variance; (f) Enhanced image of homomorphic filtering; (g) Enhanced image of the proposed algorithm

表 1 不同图像增强算法客观指标评价

Table 1. Evaluation of objective index of different image enhancement algorithms

图像 均值 信息熵 平均梯度 标准差 峰值信噪比 原始图像 111.719 7.097 1.78 56.014 —— MSR算法 158.840 7.192 1.849 43.095 23.191 SLVM算法 118.243 6.903 3.243 35.610 39.198 局部均方差算法 116.745 7.707 2.699 56.345 48.642 同态滤波算法 146.626 7.615 2.047 52.984 39.163 直方图均衡化算法 126.792 7.573 3.288 63.677 46.236 本文算法 72.530 7.895 3.365 16.649 50.78 增强幅度/% —— 2.4 2.3 73.9 4.4 表 2 边缘检测效果指标评估

Table 2. Evaluation of edge detection effect index

-

[1] 洪鼎华, 王环丽, 李武平, 等.在役P92钢蒸汽管道焊接接头中缺陷的研究[J].机械工程学报, 2017, 53(18): 113–120. doi: 10.3901/JME.2017.18.113

Hong D H, Wang H L, Li W P, et al. Study on the defects in welded joint of hot reheat steam pipe of ultra supercritical units after long-term service[J]. Journal of Mechanical Engineering, 2017, 53(18): 113–120. doi: 10.3901/JME.2017.18.113

[2] 杨先凤, 吴媛媛, 赵玲.基于Canny改进算子的油管裂纹检测算法[J].计算机工程与设计, 2018, 39(3): 798–803. doi: 10.16208/j.issn1000-7024.2018.03.035

Yang X F, Wu Y Y, Zhao L. Pipeline crack detection algorithm based on Canny detector[J]. Computer Engineering and Design, 2018, 39(3): 798–803. doi: 10.16208/j.issn1000-7024.2018.03.035

[3] 孙丽, 孙茜茜, 任亮, 等.应用光纤布喇格光栅传感器监测地下管道腐蚀的新方法研究[J].光子学报, 2012, 41(1): 6–10. doi: 10.3788/gzxb20124101.0006

Sun L, Sun Q Q, Ren L, et al. A new method for underground pipeline corrosion monitoring applied FBG[J]. Acta Photonica Sinica, 2012, 41(1): 6–10. doi: 10.3788/gzxb20124101.0006

[4] 曹建树, 曹振, 赵龙飞, 等.激光超声管道表面裂纹检测技术[J].光电工程, 2016, 43(3): 1–6. doi: 10.3969/j.issn.1003-501X.2016.03.001

Cao J S, Cao Z, Zhao L F, et al. Detecting techniques of surface crack of pipeline based on laser ultrasonic[J]. Opto-Electronic Engineering, 2016, 43(3): 1–6. doi: 10.3969/j.issn.1003-501X.2016.03.001

[5] 张盼, 陈志东, 李晓旭, 等.基于小波变换的X射线数字图像焊缝缺陷边缘检测[J].管道技术与设备, 2016(3): 41–43. doi: 10.3969/j.issn.1004-9614.2016.03.013

Zhang P, Chen Z D, Li X X, et al. X-ray digital image of weld defect based on wavelet transform edge detection[J]. Pipeline Technique and Equipment, 2016(3): 41–43. doi: 10.3969/j.issn.1004-9614.2016.03.013

[6] 王志刚, 罗清旺, 师奕兵, 等.铁磁性管道内涡流线圈耦合分析与管道参数检测[J].仪器仪表学报, 2014, 35(12): 2843–2851. doi: 10.3969/j.issn.0254-3087.2014.12.024

Wang Z G, Luo Q W, Shi Y B, et al. Analysis of eddy current coil coupling in ferromagnetic pipe and pipe's parameter detection[J]. Chinese Journal of Scientific Instrument, 2014, 35(12): 2843–2851. doi: 10.3969/j.issn.0254-3087.2014.12.024

[7] 杨金旭, 李策, 夏胜, 等.基于磁致伸缩导波的管道缺陷检测系统[J].仪表技术与传感器, 2017(6): 95–97, 167. doi: 10.3969/j.issn.1002-1841.2017.06.023

Yang J X, Li C, Xia S, et al. Magnetostrictive guided wave flaw detection system for pipeline[J]. Instrument Technique and Sensor, 2017(6): 95–97, 167. doi: 10.3969/j.issn.1002-1841.2017.06.023

[8] Su T C, Yang M D. Application of morphological segmentation to leaking defect detection in sewer pipelines[J]. Sensors, 2014, 14(5): 8686–8704. doi: 10.3390/s140508686

[9] Vriesman D, Britto A S, Zimmer A, et al. Automatic visual inspection of thermoelectric metal pipes[J]. Signal, Image and Video Processing, 2019, 13(5): 975–983. doi: 10.1007/s11760-019-01435-2

[10] Yang Z Y, Lu S H, Wu T, et al. Detection of morphology defects in pipeline based on 3D active stereo omnidirectional vision sensor[J]. IET Image Processing, 2018, 12(4): 588–595. doi: 10.1049/iet-ipr.2017.0616

[11] 王颖, 张瑞.管道内表面圆结构光视觉三维测量系统[J].红外与激光工程, 2014, 43(3): 891–896. doi: 10.3969/j.issn.1007-2276.2014.03.040

Wang Y, Zhang R. In-pipe surface circular structured light 3D vision inspection system[J]. Infrared and Laser Engineering, 2014, 43(3): 891–896. doi: 10.3969/j.issn.1007-2276.2014.03.040

[12] 吴斌, 邵震宇, 张云昊.微细管道内壁缺陷测量系统构建和技术[J].光电子·激光, 2014, 25(2): 293–298. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gdzjg201402016

Wu B, Shao Z Y, Zhang Y H. A new technology of building up defect measuring system for inner micro-pipe[J]. Journal of Optoelectronics·Laser, 2014, 25(2): 293–298. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gdzjg201402016

[13] Haertel M E M, da Costa Pinto T L F, Júnior A A G. Trinocular stereo system with object space oriented correlation for inner pipe inspection[J]. Measurement, 2015, 73: 162–170. doi: 10.1016/j.measurement.2015.05.015

[14] Land E H, McCann J J. Lightness and retinex theory[J]. Journal of the Optical Society of America, 1971, 61(1): 1–11. doi: 10.1364/JOSA.61.000001

[15] Bradley D, Roth G. Adaptive thresholding using the integral image[J]. Journal of Graphics Tools, 2007, 12(2): 13–21. doi: 10.1080/2151237X.2007.10129236

[16] 魏伟一, 任小康.基于图像信息熵的四叉树检索算法[J].佳木斯大学学报(自然科学版), 2005, 23(4): 511–514, 521. doi: 10.3969/j.issn.1008-1402.2005.04.002

Wei W Y, Ren X K. Quadtree image retrieval based on image entropy[J]. Journal of Jiamusi University (Natural Science Edition), 2005, 23(4): 511–514, 521. doi: 10.3969/j.issn.1008-1402.2005.04.002

[17] 任洪娥, 刘冕, 董本志.基于改进形态学算子的木粉边缘检测算法[J].计算机工程与应用, 2015, 51(5): 183–186. doi: 10.3778/j.issn.1002-8331.1304-0316

Ren H E, Liu M, Dong B Z. Edge detection algorithm of wood-flour based on modified morphological operator[J]. Computer Engineering and Applications, 2015, 51(5): 183–186. doi: 10.3778/j.issn.1002-8331.1304-0316

[18] 郝利华, 王明泉.改进的Canny算法在直焊缝图像缺陷边缘检测中的应用[J].火力与指挥控制, 2017, 42(7): 52–55. doi: 10.3969/j.issn.1002-0640.2017.07.012

Hao L H, Wang M Q. Application of improved canny algorithm in defect edge detection of straight weld image[J]. Fire Control & Command Control, 2017, 42(7): 52–55. doi: 10.3969/j.issn.1002-0640.2017.07.012

[19] 林卉, 赵长胜, 舒宁.基于Canny算子的边缘检测及评价[J].黑龙江工程学院学报, 2003, 17(2): 3–6, 16. doi: 10.3969/j.issn.1671-4679.2003.02.001

Lin H, Zhao C S, Shu N. Edge detection based on Canny operator and evaluation[J]. Journal of Heilongjiang Institute of Technology, 2003, 17(2): 3–6, 16. doi: 10.3969/j.issn.1671-4679.2003.02.001

[20] 陈宏希.基于品质因数的边缘检测算子性能优劣客观评价研究[J].自动化与仪器仪表, 2015(8): 8–10. doi: 10.14016/j.cnki.1001-9227.2015.08.008

Chen H X. Study on the objective evaluation of the performance of edge detection operator based on the quality factor[J]. Automation & Instrumentation, 2015(8): 8–10. doi: 10.14016/j.cnki.1001-9227.2015.08.008

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: