-

摘要:

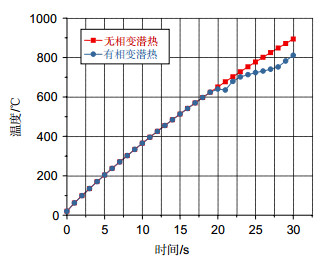

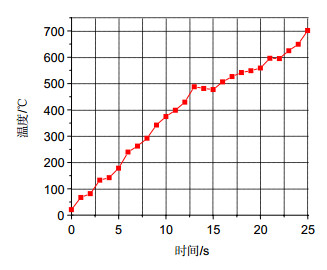

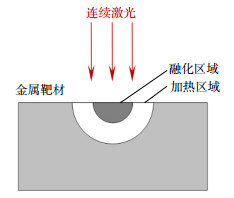

本文对连续激光辐照金属材料的峰值温度变化情况进行研究,建立了连续激光辐照材料的有限元分析模型,采用仿真分析的方法对连续激光照射铝合金圆板的峰值温度变化情况进行了研究。通过对光束抖动、光斑扩散、空气对流、材料表面氧化等不同条件仿真结果的分析,给出了各种因素对激光辐照材料峰值温度变化情况的影响,并利用等效材料比热容的方法开展了相变潜热对温升情况的影响分析。最后综合各种条件给出了在连续激光辐照铝合金材料的峰值温度变化情况,对材料的损伤进行了分析。

Abstract:

Abstract:The variation of peak temperature of metal materials irradiated by continuous wave (CW) laser is studied in this paper. We established a finite element model of metal materials irradiated by CW laser. The variation of peak temperature of aluminum alloy circular plates irradiated by CW laser is studied by simulation analysis method. By analyzing the simulation results under different conditions, such as beam drift, spot diffusion, air convection and material surface oxidation, the effects of various factors on the peak temperature of laser-irradiated materials are given, and the influence of latent heat of phase change on temperature rise is analyzed by using the method of equivalent material specific heat capacity. Finally, according to various conditions, the change of peak temperature of aluminum alloy irradiated by CW laser is given, and the damage of aluminum alloy is analyzed.

-

Key words:

- laser damage /

- temperature /

- finite element /

- phase transformation

-

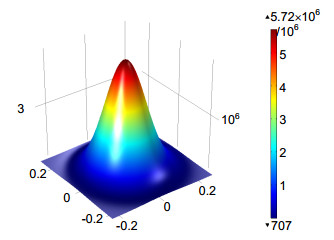

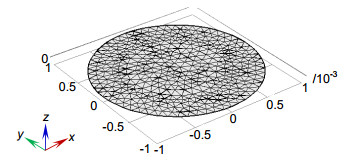

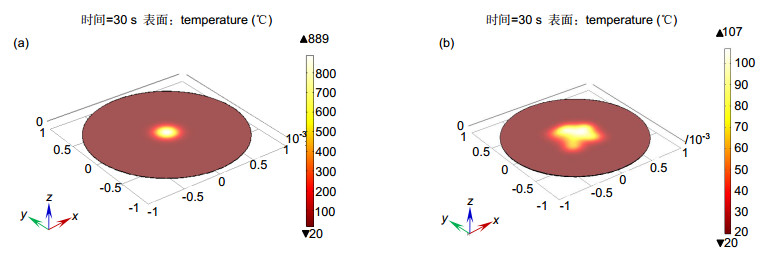

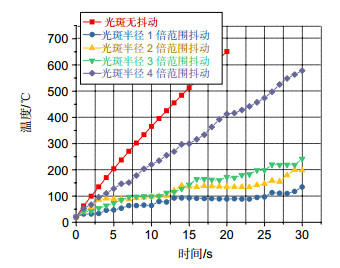

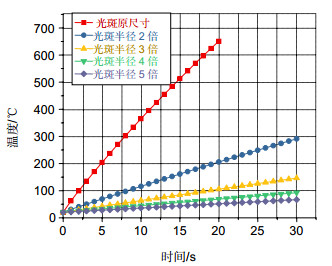

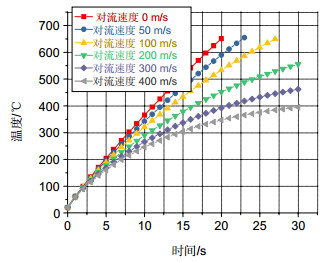

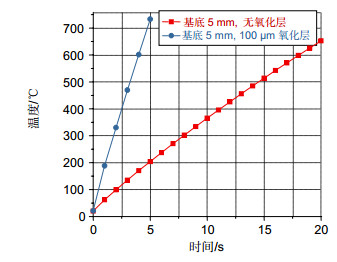

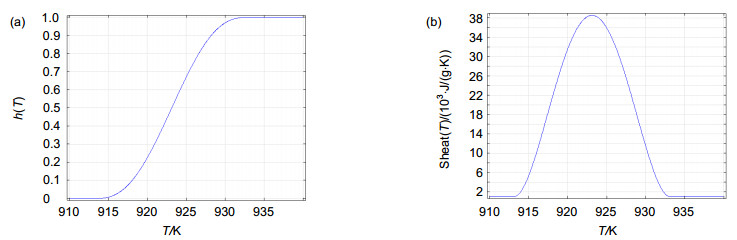

Overview: In order to study the interaction between CW laser and material, we analyzed the variation of peak temperature of aluminum alloy irradiated by CW laser. In this paper, the laser source which irradiated aluminum alloy material is approximated to a surface heat source. The finite element equation of temperature field of material surface irradiated by CW laser is established. The boundary conditions of material surface with radiation and heat exchange are given. When establishing the simulation analysis model of CW laser irradiated aluminum alloy circular plate, it is assumed that (i) the material is isotropic, (ii) the absorptivity and physical parameters of the material are independent of temperature, (iii) the heat loss is only the thermal radiation and convective heat transfer of the material surface to the environment, (iv) the material is opaque in the working wavelength range of the laser, and (v) there is no light penetrating material. A finite element model of the transient temperature field of aluminum alloy with a radius of 1 m and a thickness of 5 mm irradiated by CW laser was established. The effects of beam drift, spot diffusion, air convection and surface oxidation on the peak temperature of laser irradiated aluminum alloy were analyzed by simulation. The influence of latent heat of phase change on temperature rise is also analyzed by using the method of equivalent material specific heat capacity. Finally, according to the above conditions, the change of peak temperature of aluminum alloy irradiated by CW laser is given, and the damage of the material is analyzed. The simulation results show that the damage of CW laser irradiated materials is mainly due to thermal effect. Under the given simulation conditions, spot drift and spot diffusion will lead to a sharp drop in the peak temperature of the material compared with the normal situation. Surface convection has a significant effect only when the convection speed is high. The oxidation treatment on the surface of aluminum alloys will lead to a significant increase in laser absorption, and a significant reduction in the irradiation time to reach the melting temperature of the material. The latent heat of phase change has relatively little effect on the temperature rise of materials compared with other factors. From the final comprehensive analysis, when the laser reaches the material surface with an average power density of 127.33 W/cm2, the beam center drift range is twice the radius of the spot, and the surface convection velocity is 250 m/s, the peak temperature of the surface oxidized aluminum alloy reaches the melting temperature after 25 s. Under this condition, the material can be damaged.

-

-

表 1 材料的热物理性质

Table 1. Thermophysical properties of materials

性质 Al(2024) 密度(ρ)/(g/cm3) 2.77 热容(C)/(J/(g·K)) 1.05 热导率(k)/(W/(cm·K)) 2.38 熔化温度(Tm)/K 933 融化热(Lm)/(J/g) 400 表 2 不同光斑半径的平均功率密度

Table 2. Average power density of different spot radii

光斑半径倍数 1 2 3 4 5 平均功率密度/(W·cm-2) 127.33 31.83 14.15 7.96 5.10 表 3 氧化铝的热物理性质

Table 3. Thermophysical properties of alumina

性质 Al2O3 密度(ρ)/(g/cm3) 4.08 热容(C)/(J/(g·K)) 1.53 热导率(k)/(W/(cm·K)) 0.30 熔化温度(Tm)/K 2307 融化热(Lm)/(J/g) 1067 -

[1] 宋乃秋, 张昊春, 马超, 等.高能激光武器毁伤机理多物理场建模[J].化工学报, 2016, 67(S1): 359–365. doi: 10.11949/j.issn.0438-1157.20160612

Song N Q, Zhang H C, Mao C, et al. Multiple physical modeling for damage mechanism of high energy laser weapon[J]. CIESC Journal, 2016, 67(S1): 359–365. doi: 10.11949/j.issn.0438-1157.20160612

[2] 蒋艳锋, 江东, 钟鸣, 等.长脉冲激光对金属材料热破坏的分析[J].激光杂志, 2006, 27(2): 75–76. doi: 10.3969/j.issn.0253-2743.2006.02.035

Jiang Y F, Jiang D, Zhong M, et al. Theoretical research: the thermal damage of matel materials, under millisecond - pulsed laser irradiations[J]. Laser Journal, 2006, 27(2): 75–76. doi: 10.3969/j.issn.0253-2743.2006.02.035

[3] Darif M, Semmar N. Numerical simulation of Si nanosecond laser annealing by COMSOL multiphysics[C]//Proceedings of the COMSOL Conference 2008 Hannover. Hannover, 2008: 567–571.

[4] Hanon M M, Akman E, Oztoprak B G, et al. Experimental and theoretical investigation of the drilling of alumina ceramic using Nd: YAG pulsed laser[J]. Optics & Laser Technology, 2012, 44(4): 913–922. doi: 10.1016/j.optlastec.2011.11.010

[5] Kuang J H, Hung T P, Chen C K. A keyhole volumetric model for weld pool analysis in Nd: YAG pulsed laser welding[J]. Optics & Laser Technology, 2012, 44(5): 1521–1528.

[6] 裴旭, 吴建华.金属材料脉冲激光辐照瞬态温度场数值模拟研究[J].激光技术, 2012, 36(6): 828–831. doi: 10.1016/j.optlastec.2011.12.006

Pei X, Wu J H. Numerical simulation of transient temperature field on metal material induced by pulse laser irradiation[J]. Laser Technology, 2012, 36(6): 828–831. doi: 10.1016/j.optlastec.2011.12.006

[7] 姚红兵, 高原, 袁冬青, 等.激光辐照铝材表面温度场特征演化的数值模拟[J].激光与红外, 2015, 45(10): 1175–1179. doi: 10.3969/j.issn.1001-5078.2015.10.006

Yao H B, Gao Y, Yuan D Q, et al. Numerical simulation of characteristics evolution of aluminum surface temperature field irradiated by laser[J]. Laser & Infrared, 2015, 45(10): 1175–1179. doi: 10.3969/j.issn.1001-5078.2015.10.006

[8] 孙承纬.激光辐照效应[M].北京:国防工业出版社, 2002.

Sun C W. Effect of Laser Irradiation[M]. Beijing: National Defense Industry Press, 2002.

[9] 徐立君, 张喜和, 倪晓武, 等.不同光斑半径的连续激光作用金属靶材的温度场[J].红外与激光工程, 2007, 36(S1): 632–635. doi: 10.3969/j.issn.1007-2276.2007.z1.177

Xu L J, Zhang X H, Ni X W, et al. Temperature field of the CW-laser with different radius irradiating metal plates irradiating metal plate[J]. Infrared and Laser Engineering, 2007, 36(S1): 632–635. doi: 10.3969/j.issn.1007-2276.2007.z1.177

[10] 徐斌, 赵选科, 王莲芬, 等.强激光武器辐照弹道导弹温度场数值模拟[J].激光与红外, 2016, 46(12): 1526–1530. doi: 10.3969/j.issn.1001-5078.2016.12.018

Xu B, Zhao X K, Wang L F, et al. Numerical simulation of the temperature field of the ballistic missile irradiated by high intensity laser[J]. Laser & Infrared, 2016, 46(12): 1526–1530. doi: 10.3969/j.issn.1001-5078.2016.12.018

[11] 李清源.强激光对飞行器的毁伤效应[M].北京:中国宇航出版社, 2012.

Li Q Y. Damage Effects of Vehicles Irradiated by Intense Lasers[M]. Beijing: China Astronautic Publishing House, 2012.

[12] Brückner M, Sch fer J H, Uhlenbusch J. Ellipsometric measurement of the optical constants of solid and molten aluminum and copper at λ=10.6μm[J]. Journal of Applied Physics, 1989, 66(3): 1326–1332. doi: 10.1063/1.344431

[13] 王文宝, 张凯华, 于坤. Al5052和Al6061红外光谱发射率的对比研究[J].兴义民族师范学院学报, 2015(4): 110–114, 118. doi: 10.3969/j.issn.1009-0673.2015.04.022

Wang W B, Zhang K H, Yu K. A comparative research on the infrared spectral emissivity of Al5052 and Al6061[J]. Journal of Xingyi Normal University for Nationalities, 2015(4): 110–114, 118. doi: 10.3969/j.issn.1009-0673.2015.04.022

[14] 张凯华, 于坤, 刘玉芳, 等.大气环境中Al5052光谱发射率研究[J].河南师范大学学报(自然科学版), 2014, 42(1): 36–40. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=henansfdxxb201401008

Zhang K H, Yu K, Liu Y F, et al. Normal spectral emissivity of AL5052 in atmospheric environment[J]. Journal of Henan Normal University (Natural Science Edition), 2014, 42(1): 36–40. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=henansfdxxb201401008

[15] 马健, 赵扬, 周凤艳, 等.基于有限元的脉冲激光辐照材料温度场研究[J].激光与红外, 2015, 45(1): 27–31. doi: 10.3969/j.issn.1001-5078.2015.01.006

Ma J, Zhao Y, Zhou F Y, et al. Study on temperature field of materials irradiated by pulse laser based on FEM[J]. Laser & Infrared, 2015, 45(1): 27–31. doi: 10.3969/j.issn.1001-5078.2015.01.006

[16] 魏向禹, 惠鑫刚, 梁智国.铝合金表面微弧氧化与阳极氧化工艺介绍[J].中国金属通报, 2017(9): 69–70. http://www.cqvip.com/QK/60118X/20179/673511895.html

Wei X Y, Hui X G, Liang Z G. Introduction of micro-arc oxidation and anodic oxidation technology on aluminum alloy surface[J]. China Metal Bulletin, 2017(9): 69–70. http://www.cqvip.com/QK/60118X/20179/673511895.html

[17] 刘宝明, 王燕燕, 沈志华, 等.材料法向光谱发射率测定装置[J].计量学报, 1986, 7(3): 204–211. http://d.old.wanfangdata.com.cn/Conference/133274

Liu B M, Wang Y Y, Shen Z H, et al. An apparatus for measuring normal spectral emittance of substances[J]. Acta Metrologica Sinica, 1986, 7(3): 204–211. http://d.old.wanfangdata.com.cn/Conference/133274

[18] 焦路光, 杨在富, 王嘉睿.气流环境中激光烧蚀铝靶的数值模拟研究[J].激光与红外, 2016, 46(2): 145–149. doi: 10.3969/j.issn.1001-5078.2016.02.004

Jiao L G, Yang Z F, Wang J R. Numerical simulation on laser ablation of aluminum target under tangential airflow[J]. Laser & Infrared, 2016, 46(2): 145–149. doi: 10.3969/j.issn.1001-5078.2016.02.004

[19] Radice J J, Joyce P J, Tresansky A C, et al. A COMSOL model of damage evolution due to high energy laser irradiation of partially absorptive materials[C]//Proceedings of the 2012 COMSOL Conference in Boston, Boston, 2012.

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: