Microtube fabrication based on femtosecond Bessel beam and its flexible driving with external magnetic field

-

摘要:

微管道是微纳领域最基本的模型之一,其结构简单、均匀,应用广泛。本文提出一种利用飞秒贝塞尔光进行激光直写,结合磁控溅射金属镀层,加工可磁驱动微管道的新方法。利用空间光调制器将飞秒激光调制成飞秒贝塞尔光,通过高数值孔径的物镜聚焦,配合精密三维压电平台的移动,实现了微管道的拉伸加工;通过后续磁控溅射镍处理后,微管道具有超顺磁特性,利用外部磁场可以有效实现驱动。本文详细研究了利用空间光调制器产生的飞秒贝塞尔光的传播和聚焦特性,提出的微管道加工新方法可实现微管道直径、长度、排布的灵活控制,加工效率高;经磁控溅射镍处理的微管道可以利用外部磁场实现在液体环境下沿特定路径的可控驱动,运动灵敏度高,环境适应性强。这种新的微管道加工方法具有灵活、可控、高效的优点,所加工的可驱动微管道在无创手术、靶向药物运输、生物成像与传感、微环境净化等领域具有广阔的应用前景。

Abstract:

Abstract:Microtube, with simple and uniform geometry, is one of the basic structures in micro/nano field. We present a method for the fabrication of magnetic drivable microtubes, by direct femtosecond laser writing combined with magnetron sputtering with metal layer. Femtosecond laser beam is modulated into Bessel beam with spatial light modulator (SLM), and then Bessel beam is focused with a high numerical aperture objective. Microtubes are fabricated by scanning focused femtosecond Bessel beam in a sample anchored on a three dimension stage. Followed by magnetron sputtering a nickel layer, the microtubes exhibit supermagnetic property and can be flexibly driven by external magnetic field. In this study, the propagation and high numerical aperture focusing properties of femtosecond Bessel beams are investigated. Microtubes, with well controlled diameter, length and distribution are efficiently fabricated. Rapid steering of nickel coated microtubes along specific route in fluid environment with external magnetic field has been realized. The steering of microtubes can be realized in various fluid environments. This method is flexible, controllable and efficient and the fabricated drivable microtubes have a promising applications in noninvasive surgery, targeted drug delivery, bioimaging or biosensing and microenvironment cleaning.

-

Key words:

- microtube /

- spatial light modulation /

- Bessel beam /

- magnetic driving

-

Microtube, with simple and uniform geometry, is one of the basic structures in micro/nano field. Mircotube is widely used in the fields of microoptics, biomedical devices, microfluidics, micropumps, microsensors and micromotors, especially magnetically driven motors are envisioned to be involved in various tasks such as directed drug delivery, isolation of biological targets, microsurgery, bioassay, bioimaging, environmental monitoring, remediation processes, and so on. But current fabrication methods such as self-rolling of organic or inorganic films, accumulation of nanoparticles, mask-based diffraction lithography and holographic lithography are only suitable for the preparation of microtubes with certain periodic or specific profiles due to the limitation of inherent fabrication principles, and thus suffered from low flexibility and weak designability. We present a method for the fabrication of magnetic drivable microtubes, by direct femtosecond laser writing combined with magnetron sputtering with metal layer. Femtosecond laser beam is modulated into Bessel beam with spatial light modulator (SLM), and then Bessel beam is focused with a high numerical aperture objective. Microtubes are fabricated by scanning focused femtosecond Bessel beam, a circular beam pattern, in a sample anchored on a three dimension stage. This technology keeps the high resolution of two-photon polymerization and greatly reduces the consumed time by two magnitudes. Followed by magnetron sputtering a nickel layer, the microtubes exhibit paramagnetic property and can be flexibly driven by external magnetic field. The propagation and high numerical aperture focusing properties of femtosecond Bessel beams are investigated, which constructs a solid base for the fabrication parameters optimization. By modulating the phase hologram loaded to the SLM, the intensity distribution of femtosecond laser beam is controlled. Microtubes, with well controlled diameter, length and distribution are efficiently fabricated. Complicated microtube arrays, including 2×1, 2×2 arrays, 5 tubes microrocket and 9 tubes microrocket are fabricated rapidly within several seconds. Individual microtube in these arrays keeps its original shape without any deformation and interaction with each other. A sputtered 80 nm Ni layer imposes the microtubes with paramagnetic property. Rapid steering of the nickel coated microtubes along specific route in fluid environment with external magnetic field produced by columnar magnet has been realized. Controlled driving of microtubes along a “NANO” type trajectory has been achieved. The magnetic driving of microtubes will not be affected by environmental variation, electric signal, temperature signal and optical signal. This method is flexible, controllable as well as efficient, and the fabricated drivable microtubes have promising applications in noninvasive surgery, targeted drug delivery, bioimaging or biosensing and microenvironment cleaning

-

-

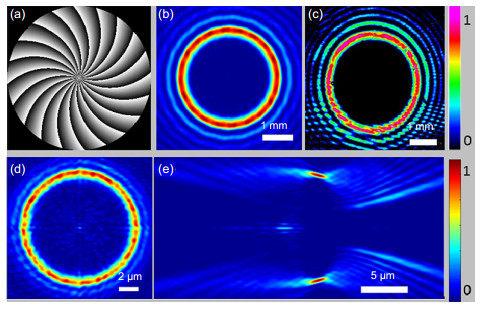

图 1 贝塞尔光全息相位图与光强分布. (a) n=20, r0=480贝塞尔光全息图. (b)飞秒贝塞尔光光强分布计算仿真图. (c)飞秒贝塞尔光光强分布实测图. (d)聚焦后飞秒贝塞尔光焦面光强分布图. (e)聚焦后飞秒贝塞尔光在传播方向上的光强分布图.

Figure 1. The phase diagram and intensity distribution of Bessel beams. (a) n=20, r0=480 Bessel beam hologram. (b) Intensity distribution simulation of femtosecond Bessel beam. (c) Measurement of light intensity distribution of Bessel beam. (d) Microscopic distribution of light intensity of femtosecond Bessel beam. (e) The intensity distribution of the Bessel beam along the propagation direction.

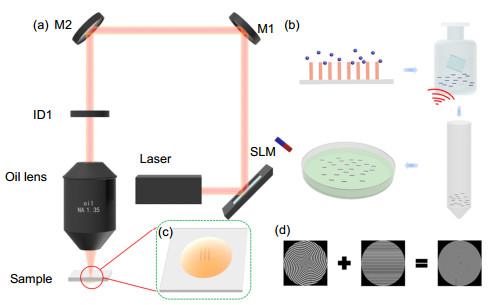

图 2 飞秒贝塞尔光加工系统示意图与工艺流程图. (a)飞秒贝塞尔光全息加工示意图. (b)微管道后处理工艺流程图. (c)微管道放大示意图. (d)加载SLM上的全息相位图:贝塞尔相位板叠加闪耀光栅.

Figure 2. Schematic diagram of femtosecond Bessel beam processing system and flow chart of microtubes fabrication procedure. (a) Schematic diagram of femtosecond Bessel beam fabrication system. (b) Flow chart of microtubes post-treatment process. (c) Enlarged image of microtubes. (d) Hologram loaded on SLM: Bessel hologram and Blazed grating.

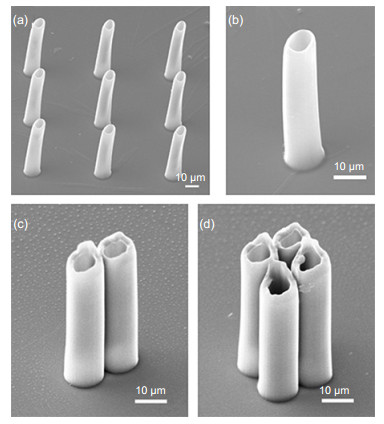

图 3 贝塞尔光全息加工结构SEM图. (a)贝塞尔管道阵列图. (b)单个贝塞尔管道放大图. (c), (d)分别为2×1、2×2型,高50μm微管道.

Figure 3. SEM images of Bessel light holographic processing structure. (a) SEM image of Bessel microtube arrays. (b) Enlarged image of single Bessel microtube. (c), (d) SEM image of 2×1 and 2×2 type, microtubes with 50 μm height, respectively.

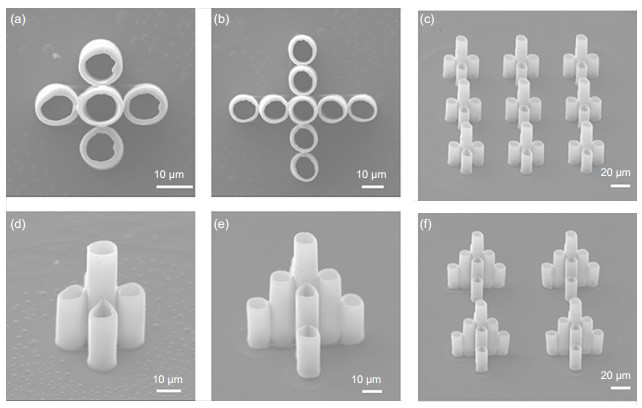

图 4 飞秒贝塞尔光全息加工复杂结构SEM图. (a), (b)分别为5管微火箭、9管微火箭俯视图. (d), (e)分别为45°视图.(c), (f)分别为5管微火箭、9管微火箭阵列.

Figure 4. SEM images of complex structure fabricated by femtosecond Bessel beam. (a), (b) Top view of 5 tubes microrocket, 9 tubes microrocket and (d), (e) 45° captured images of 5 tubes microrocket, 9 tubes microrocket. (c), (f) Microrockets arrays.

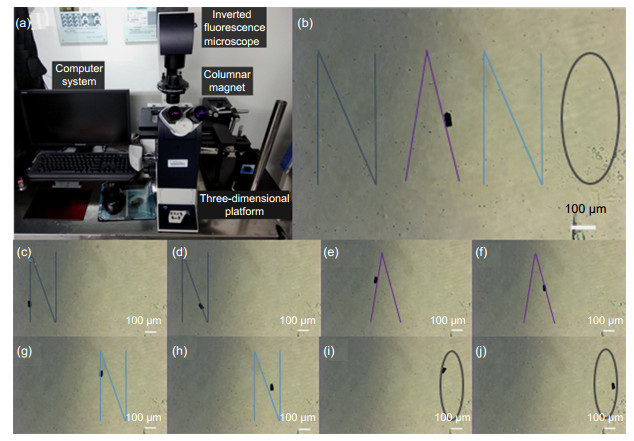

图 5 磁驱动系统示意图与微管道在外部磁场作用下的运动轨迹. (a)磁驱动系统示意图. (b)微管道完成“NANO”型运动轨迹. (c)~(j)不同时刻微管道所在位置.

Figure 5. Magnetic drive system diagram and the trajectory of microtube under external magnetic field. (a) Magnetic drive system diagram. (b) Microtube complete "NANO" type trajectory. (c)~(j) The location of microtube at different time.

-

[1] Xi Wang, Solovev A A, Ananth A N, et al. Rolled-up magnetic microdrillers: towards remotely controlled minimally invasive surgery[J]. Nanoscale, 2013, 5(4): 1294-1297. doi: 10.1039/C2NR32798H

[2] Kagan D, Benchimol M J, Claussen J C, et al. Acoustic droplet vaporization and propulsion of perfluorocarbon-loaded microbullets for targeted tissue penetration and deformation[J]. Angewandte Chemie International Edition, 2012, 124(30): 7637-7640.

[3] Li Jinxing, Thamphiwatana S, Liu Wenjuan, et al. Enteric micromotor can selectively position and spontaneously propel in the gastrointestinal tract[J].ACS Nano, 2016, 10(10): 9536-9542. doi: 10.1021/acsnano.6b04795

[4] Gao Wei, Kagan D, Pak O S, et al. Cargo-towing fuel-free magnetic nanoswimmers for targeted drug delivery[J]. Small, 2012, 8(3): 460-467. doi: 10.1002/smll.201101909

[5] Yang Liang, Ji Shengyun, Xie Kenan, et al. High efficiency fabrication of complex microtube arrays by scanning focused femtosecond laser Bessel beam for trapping/releasing biological cells[J]. Optics Express, 2017, 25(7): 8144–8157. doi: 10.1364/OE.25.008144

[6] Kim S, Qiu Famin, Kim S, et al. Fabrication and characterization of magnetic microrobots for three-dimensional cell culture and targeted transportation[J]. Advanced Materials, 2013, 25(41): 5863-5868. doi: 10.1002/adma.201301484

[7] Vilela D, Parmar J, Zeng Yongfei, et al. Graphene-based microbots for toxic heavy metal removal and recovery from water[J]. Nano Letters, 2016, 16(4): 2860–2866. doi: 10.1021/acs.nanolett.6b00768

[8] Zhao Guanjia, Sanchez S, Schmidt O G, et al. Poisoning of bubble propelled catalytic micromotors: the chemical environment matters[J]. Nanoscale, 2013, 5(7): 2909-2914. doi: 10.1039/c3nr34213a

[9] Solovev A A, Mei Yongfeng, Bermúdez Urena E, et al. Catalytic microtubular jet engines self-propelled by accumulated gas bubbles[J]. Small, 2009, 5(14): 1688-1692. doi: 10.1002/smll.v5:14

[10] Solovev A A, Xi Wang, Gracias D H, et al. Self-propelled nanotools[J]. ACS Nano, 2012, 6(2): 1751-1756. doi: 10.1021/nn204762w

[11] Sitt A, Soukupova J, Miller D, et al. Microscale rockets and picoliter containers engineered from electrospun polymeric microtubes[J]. Small, 2016, 12(11): 1432-1439. doi: 10.1002/smll.v12.11

[12] Stankevicius E, Gertus T, Rutkauskas M, et al. Fabrication of micro-tube arrays in photopolymer SZ2080 by using three different methods of a direct laser polymerization technique[J]. Journal of Micromechanics and Microengineering, 2012, 22(6): 065022. doi: 10.1088/0960-1317/22/6/065022

[13] Sattayasamitsathit S, Kou Huanhuan, Gao Wei, et al. Fully loaded micromotors for combinatorial delivery and autonomous release of cargoes[J]. Small, 2014, 10(14): 2830-2833. doi: 10.1002/smll.201303646

[14] Gao Wei, Dong Rengfeng, Thamphiwatana S, et al. Artificial micromotors in the mouse's stomach: A step toward in vivo use of synthetic motors[J]. ACS Nano, 2015, 9(1): 117-123. doi: 10.1021/nn507097k

[15] Solovev A A, Smith E J, Bof' Bufon C C, et al. Light-controlled propulsion of catalytic microengines[J]. Angewandte Chemie International Edition, 2011, 50(46): 10875-10878. doi: 10.1002/anie.v50.46

[16] Sharma R, Velev O D. Remote steering of self-propelling microcircuits by modulated electric field[J]. Advanced Functional Materials, 2015, 25(34): 5512-5519. doi: 10.1002/adfm.201502129

[17] Balk A L, Mair L O, Mathai P P, et al. Kilohertz rotation of nanorods propelled by ultrasound, traced by microvortex advection of nanoparticles[J]. ACS Nano, 2014, 8(8): 8300-8309. doi: 10.1021/nn502753x

[18] Tottori S, Zhang Li, Qiu Famin, et al. Magnetic helical micromachines: fabrication, controlled swimming, and cargo transport[J]. Advanced Materials, 2012, 24(6): 811-816. doi: 10.1002/adma.201103818

[19] Servant A, Qiu Famin, Mazza M, et al. Controlled in vivo swimming of a swarm of bacteria-like microrobotic flagella[J]. Advanced Materials, 2015, 27(19): 2981-2988. doi: 10.1002/adma.201404444

[20] 林培秋, 王辉, 庞辉.基于液晶空间光调制器的相息图扫描三维成像[J].光电工程, 2010, 37(3): 138-143. http://www.oejournal.org/J/OEE/Article/Details/A171225000011/CN

Lin Peiqiu, Wang Hui, Pang Hui. Scanning three-dimensional image with kinoform based on liquid crystal spatial light modulation[J]. Opto-Electronic Engineering, 2010, 37(3): 138-143. http://www.oejournal.org/J/OEE/Article/Details/A171225000011/CN

[21] 饶生龙, 吴培超, 张晨初, 等.基于空间光调制器的能量可控飞秒激光加工[J].中国激光, 2017, 44(1): 0102008. http://www.opticsjournal.net/Articles/abstract?aid=OJ170110000017aHdKgM

Rao Shenglong, Wu Peichao, Zhang Chenchu, et al. Energy-controllable femtosecond laser fabrication based on spatial light modulator[J]. Chinese Journal of Lasers, 2017, 44(1): 0102008. http://www.opticsjournal.net/Articles/abstract?aid=OJ170110000017aHdKgM

[22] Bhuian B, Winfield R J, O'Brien S, et al. Pattern generation using axicon lens beam shaping in two-photon polymerisation[J]. Applied Surface Science, 2007, 254(4): 841-844. doi: 10.1016/j.apsusc.2007.08.071

[23] Mhanna R, Qiu Famin, Zhang Li, et al. Artificial bacterial flagella for remote-controlled targeted single-cell drug delivery[J]. Small, 2014, 10(10): 1953-1957. doi: 10.1002/smll.201303538

[24] Ding Yun, Qiu Famin, Solvas X C I, et al. Microfluidic-based droplet and cell manipulations using artificial bacterial flagella[J]. Micromachines, 2016, 7(2): 25. doi: 10.3390/mi7020025

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: