Development of a modeling method for monitoring tunnel deformation based on active panoramic vision technique

-

摘要:

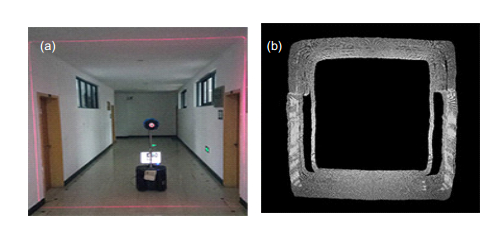

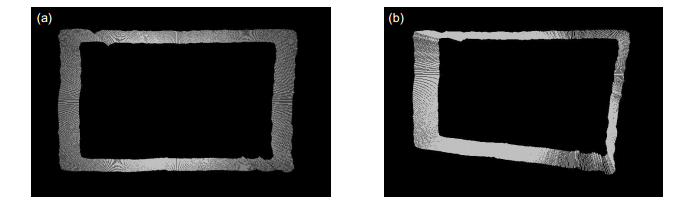

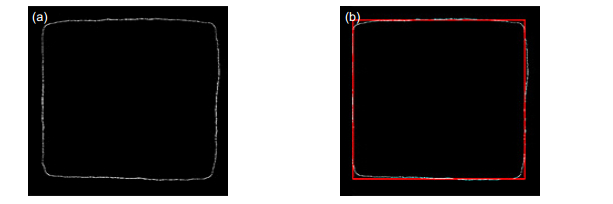

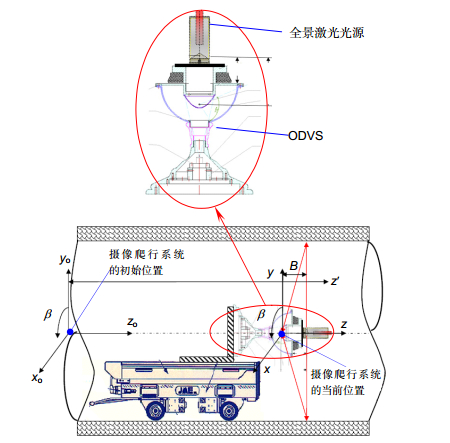

针对隧道距离长、运维检测时间跨度长、可检测时间短、形变数据变化小等特点,本文提出了一种基于主动式全景视觉的隧道全断面变形检测方法。首先通过配置在隧道检测装置上的主动式全景视觉传感器对隧道横断面进行全景扫描,获取隧道全景切面扫描图像;接着通过改进的高斯曲线拟合法提取全景切面扫描图像上的亚像素激光中心点,并采用贝塞尔曲线对其进行平滑处理;然后根据全方位视觉传感器的标定结果解析出隧道横断面上内壁的几何信息;再利用隧道横断面上内壁三维点云数据进行三维重建;最后,对重构的隧道模型进行了精度分析。实验研究表明:基于主动式全景视觉的隧道全断面变形的检测方法具有检测速度快、实时性好、数据全面、可视化程度高等优点,能满足对狭长隧道进行快速定性定量分析的需求。

Abstract:

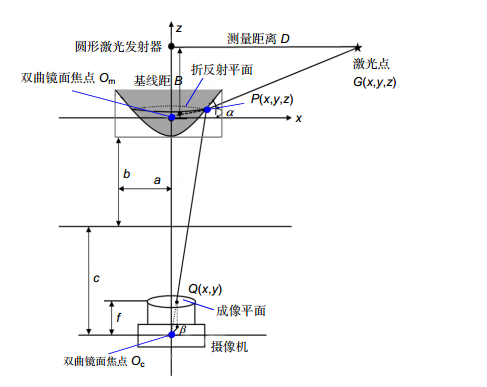

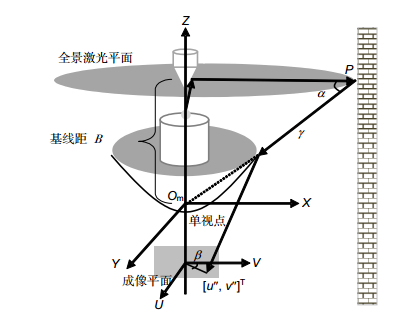

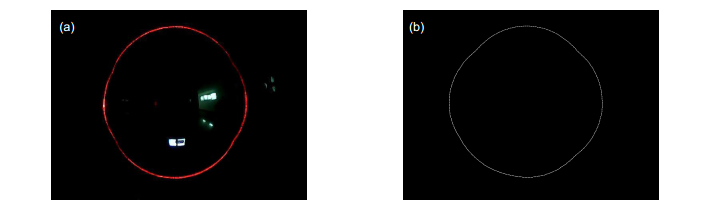

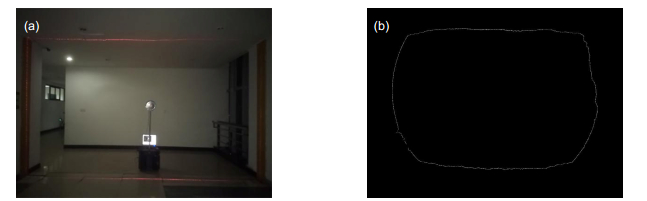

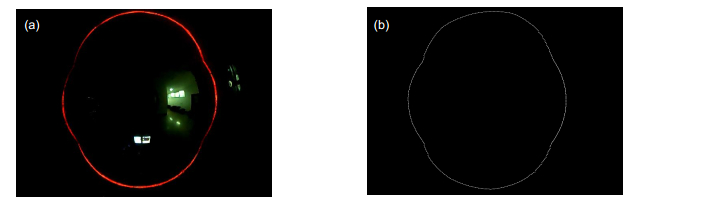

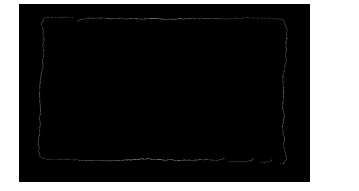

Abstract:Aiming at the characteristics of long-distance tunnel, long maintenance intervals, limited repairing time and small changes in the deformation data, this paper presents a detection method of tunnel deformation based on active omni-directional vision tunnel section deformation. Firstly, the active panoramic vision sensor (ASODVS) is installed at the tunnel and detecting device scans the cross section of tunnel to acquire tunnel section panoramic images. Secondly, the sub-pixel center of the panoramic image is extracted by the improved Gauss curve fitting method, and the smooth processing is performed by using the Bezier curves. Thirdly, the system analyzes the geometry information of the tunnel cross-section of the inner wall through calibration results of omnidirectional vision sensor. The tunnel cross section 3D point cloud data are used for 3D reconstruction. Finally, the precision of the tunnel reconstruction model is analyzed. The experimental results show the method has the advantages of high speed acquisition, real-time, comprehensive data and good visualization. It can meet the needs of the rapid qualitative and quantitative analyses.

-

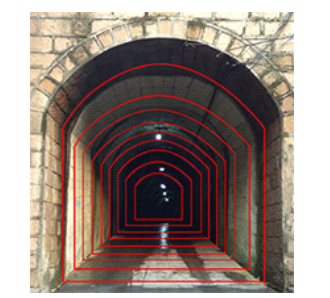

Abstract: The tunnel is a civil engineering structure and the product for the human breaking through the boundaries of the natural environment, to improve the utilization of underground space and the traffic conditions. In 1970, the Organisation for Economic Co-operation and Development held a tunnel meeting that, after synthesizing the various factors, defined the tunnel as follows: "In some applications, under the ground in any way, shape and the size of cross-sectional area is larger than 2 square metres according to regulations".

As tunnel is an important part of the transport facility, it is necessary to inspect and keep the tunnel system in good condition periodically. The main rock mass structure appears varying degrees in different parts of deformation and significantly lower than design life due to the technology limitations and force majeure during the tunnel construction and its operation. The tunnel health problems impact the path transportation security. How to detect the tunnel deformation quickly becomes the urgent problem to be solved. Most of the existing non-machine vision detection methods have the disadvantages of large measurement errors, long time, less-automated and susceptibility to the surrounding environment. There are some shortcomings of machine vision detection method, such as high cost, large number of images acquisition, complicated data processing and poor real-time performance.

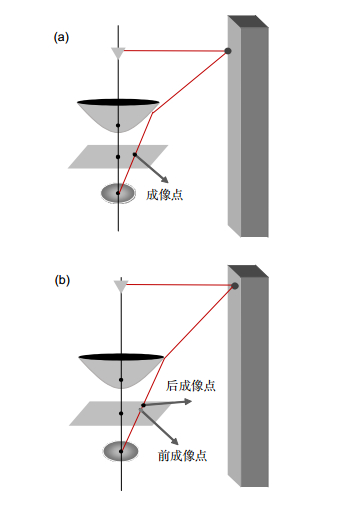

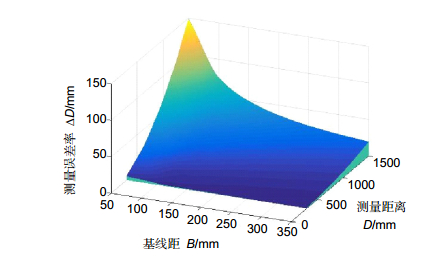

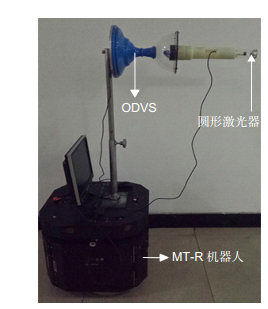

Aiming at the above problems and the characteristics of long-distance tunnel, long maintenance intervals, limited repairing time, and small changes in the deformation data, this paper designs and implements the modeling method for monitoring tunnel deformation based on active stereo-omnidirectional vision sensor. Firstly, the active panoramic vision sensor (ASODVS) which is composed of omni-directional vision sensor (ODVS) and circular laser light source is installed at the tunnel detecting device scanning the cross section of tunnel to acquire tunnel section panoramic images. Secondly, the sub-pixel center of the panoramic image is extracted by the improved Gauss curve fitting method, and the smooth processing is performed by using the Bezier curves. Thirdly, the system analyzes the geometry information of the tunnel cross-section of the inner wall through calibration results of omnidirectional vision sensor. The tunnel cross section 3D point cloud data are used for 3D reconstruction. Finally, the precision of the tunnel reconstruction model is analyzed. The experimental results show the method has the advantages of high speed acquisition, real-time, comprehensive data and good visualization. It can meet the needs of the rapid qualitative and quantitative analyses.

-

-

表 1 ODVS的标定参数.

Table 1. The calibration parameters of ODVS.

a0 a2 a4 平均误差/ pixel -75.8903 0.0026 0.00001 0.38 A t 中心点 $\left[{\begin{array}{*{20}{c}} {0.999}&0\\ {\begin{array}{*{20}{l}} 0 \end{array}}&1 \end{array}} \right]$ $\left[{\begin{array}{*{20}{c}} {49.461}\\ {-15.692} \end{array}} \right]$ $\left[\begin{array}{l} 311.850\\ 235.891 \end{array} \right]$ 表 2 高度和宽度分析表.

Table 2. Height and width analyses.

测量值/mm 实际值/mm 相对误差/(%) 高度 2835.2 2860 0.86 2872.9 2860 0.45 2867.4 2860 0.25 2915.0 2860 1.92 2907.6 2860 1.66 2873.6 2860 0.48 宽度 2648.5 2640 0.32 2735.6 2640 3.62 2728.3 2640 3.34 2705.2 2640 2.47 2712.7 2640 2.75 2605.0 2640 1.33 表 3 截面面积分析表.

Table 3. Sectional area analyses.

面积 测量值/m3 实际值/m3 相对误差/(%) 不含门

包含门7.7412

8.33957.5504

8.33840.25

0.12表 4 特征点位置分析表.

Table 4. The location of feature point analyses.

特征点 测量值/mm 实际值/mm 误差/(%) A (-1289, 1446) (-1320, 1430) 0.46 B (1306, 1453) (1320, 1430) 0.39 C (-1309, -1405) (-1320, -1430) 1.33 D (1358, -1423) (1320, -1430) 1.07 -

[1] 吴斌, 杨松.非正交轴系激光经纬仪测量技术研究[J].激光技术, 2015, 39(5): 603-609. doi: 10.7510/jgjs.issn.1001-3806.2015.05.005

Wu Bin, Yang Song. Research of measurement technology of non-orthogonal shaft laser theodolites[J]. Laser Technology, 2015, 39(5): 603-609. doi: 10.7510/jgjs.issn.1001-3806.2015.05.005

[2] 曾鼎华, 张永兴, 阴可, 等.三角形量测法在隧道变形监测中的应用研究[J].水文地质工程地质, 2005, 32(5): 113-115. https://www.wenkuxiazai.com/doc/5dcfd81bff00bed5b9f31d10-2.html

Zeng Dinghua, Zhang Yongxing, Yin Ke, et al. Application of diagonal measurement method in the displacement monitoring of tunnel[J]. Hydrogeology & Engineering Geology, 2005, 32(5): 113-115. https://www.wenkuxiazai.com/doc/5dcfd81bff00bed5b9f31d10-2.html

[3] 王泰典, 庄海岳, 邱雅筑, 等.微变监测在营运中隧道稳定评估之应用[J].建筑监督检测与造价, 2009, 2(10): 28-35. http://www.cqvip.com/qk/70550X/200910/1003481017.html

Wang Taidian, Zhuang Haiyue, Qiu Yazhu, et al. The application of micro-transformer monitor for the operation of the tunnel stability assessment[J]. Supervision Test and Cost of Construction, 2009, 2(10): 28-35. http://www.cqvip.com/qk/70550X/200910/1003481017.html

[4] Bassett R H, Kimmance J P, Rasmussen C. An automated electrolevel deformation monitoring system for tunnels[J]. Proceedings of the Institution of Civil Engineers-Geotechnical Engineering, 1999, 137(3): 117-125. doi: 10.1680/gt.1999.370301

[5] Chaiyasarn K. Damage detection and monitoring for tunnel inspection based on computer vision[D]. Cambridge: University of Cambridge, 2014.

https://www.researchgate.net/publication/303384515_Damage_detection_and_monitoring_for_tunnel_inspection_based_on_computer_vision [6] Olsson C, Enqvist O. Stable structure from motion for unordered image collections[C]//Scandinavian Conference on Image Analysis. Springer-Verlag, 2011: 524-535.

http://www.springerlink.com/content/232488031222u776 [7] 周奇才, 金奇, 高嵩, 等.基于激光测距技术的隧道断面形变检测系统[J].测控技术, 2010, 29(5): 44-46, 49. http://www.docin.com/p-779227690.html

Zhou Qicai, Jin Qi, Gao Song, et al. A tunnel cross-section deformation detection system based on laser ranging technology[J]. Measurement & Control Technology, 2010, 29(5): 44-46, 49. http://www.docin.com/p-779227690.html

[8] Izvoltova J, Villim A, Kozak P. Determination of geometrical track position by robotic total station[J]. Procedia Engineering, 2014, 91: 322-327. doi: 10.1016/j.proeng.2014.12.068

[9] Reshetyuk Y. Investigation and calibration of pulsed time-of-flight terrestrial laser scanners[D]. Stockholm: KTH Royal Institute of Technology, 2006.

https://www.researchgate.net/publication/239563997_Investigation_and_calibration_of_pulsed_time-of-flight_terrestrial_laser_scanners [10] 谢雄耀, 卢晓智, 田海洋, 等.基于地面三维激光扫描技术的隧道全断面变形测量方法[J].岩石力学与工程学报, 2013, 32(11): 2214-2224. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yslxygcxb201311006

Xie Xiongyao, Lu Xiaozhi, Tian Haiyang, et al. Development of a modeling method for monitoring tunnel deformation based on terrestrial 3d laser scanning[J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(11): 2214-2224. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yslxygcxb201311006

[11] Seo D J, Lee J C, Lee Y D, et al. Development of cross section management system in tunnel using terrestrial laser scanning technique[C]. The International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, Beijing, 2008, 36: 573-582.

https://www.researchgate.net/publication/254056814_DEVELOPMENT_OF_CROSS_SECTION_MANAGEMENT_SYSTEM_IN_TUNNEL_USING_TERRESTRIAL_LASER_SCANNING_TECHNIQUE [12] Han J Y, Guo J, Jiang Y S. Monitoring tunnel profile by means of multi-epoch dispersed 3-D LIDAR point clouds[J]. Tunnelling and Underground Space Technology, 2013, 33: 186-192. doi: 10.1016/j.tust.2012.08.008

[13] Delaloye D. Development of a new methodology for measuring deformation in tunnels and shafts with terrestrial laser scanning (LIDAR) using elliptical fitting algorithms[D]. Ontario, Canada: Queen's University Kingston, 2012.

https://qspace.library.queensu.ca/handle/1974/7202 [14] 汤一平, 叶永杰, 朱艺华, 等. 智能全方位视觉传感器及其应用研究[J]. 传感技术学报, 2007, 20(6): 1316-1320. http://www.cqvip.com/Main/Detail.aspx?id=24684831

Tang Yiping, Ye Yongjie, Zhu Yihua, et al. Research on intelligent Omni-Directional Vision Sensors and their applications[J]. Chinese Journal of Sensors and Actuators, 2007, 20(6): 1316-1320. http://www.cqvip.com/Main/Detail.aspx?id=24684831

[15] 汤一平, 王庆, 陈敏智, 等. 立体全方位视觉传感器的设计[J]. 仪器仪表学报, 2010, 31(7): 1520-1527. http://www.cqvip.com/QK/94550X/201007/34749178.html

Tang Yiping, Wang Qing, Chen Minzhi, et al. Design of stereo Omni-directional vision sensor[J]. Chinese Journal of Scientific Instrument, 2010, 31(7): 1520-1527. http://www.cqvip.com/QK/94550X/201007/34749178.html

[16] Mičušík B. Two-view geometry of omnidirectional cameras[D]. Prague: Czech Technical University, 2004.

https://www.researchgate.net/publication/268256941_Two-View_Geometry_of_Omnidirectional_Cameras [17] Yamashita A, Matsui K, Kawanishi R, et al. Self-localization and 3-D model construction of pipe by earthworm robot equipped with omni-directional rangefinder[C]. 2011 IEEE International Conference on Robotics and Biomimetics, Karon Beach, Phuket, 2011: 1017-1023.

http://www.researchgate.net/publication/254024507_Self-localization_and_3-D_model_construction_of_pipe_by_earthworm_robot_equipped_with_omni-directional_rangefinder -

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: