| Citation: | Yang Li, Lianwei Chen, Fang Kong, et al. Functional micro‐concrete 3D hybrid structures fabricated by two‐photon polymerization[J]. Opto-Electronic Engineering, 2017, 44(4): 393-399. doi: 10.3969/j.issn.1003-501X.2017.04.002 |

Functional micro‐concrete 3D hybrid structures fabricated by two‐photon polymerization

-

Abstract

Arbitrary micro-scale three-dimensional (3D) structures fabrication is a dream to achieve many exciting goals that have been pursued for a long time. Among all these applications, the direct 3D printing to fabricate human organs and integrated photonic circuits are extraordinary attractive as they can promote the current technology to a new level. Among all the 3D printing methods available, two-photon polymerization (2PP) is very competitive as it is the unique method to achieve sub-micron resolution to make any desired tiny structures. For the conventional 2PP, the building block is the photoresist. However, the requirement for the building block is different for different purposes. It is very necessary to investigate and improve the photoresist properties according to different requirements. In this paper, we presented one hybrid method to modify the mechanical strength and light trapping efficiency of the photoresist, which transfers the photoresist into the micro-concretes. The micro-concrete structure can achieve ±22% strength modification via a silica nano-particles doping. The structures doped with gold nano-particles show tunable plasmonic absorption. Dye doped hybrid structure shows great potential to fabricate 3D micro-chip laser.

-

Keywords:

- 3D nano-printing /

- two-photon polymerization /

- hybrid /

- micro-concrete

-

-

References

[1] Mironov V, Boland T, Trusk T, et al. Organ printing: computer-aided jet-based 3D tissue engineering[J]. Trends in Biotechnology, 2003, 21(4): 157-161. doi: 10.1016/S0167-7799(03)00033-7 [2] Seitz H, Rieder W, Irsen S, et al. Three-dimensional printing of porous ceramic scaffolds for bone tissue engineering[J]. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 2005, 74B(2): 782-788. doi: 10.1002/(ISSN)1552-4981 [3] Giordano R A, Wu B M, Borland S W, et al. Mechanical properties of dense polylactic acid structures fabricated by three dimensional printing[J]. Journal of Biomaterials Science, Polymer Edition, 1997, 8(1): 63-75. doi: 10.1163/156856297X00588 [4] Zhou Wenhui, Kuebler S M, Braun K L, et al. An efficient two-photon-generated photoacid applied to positive-tone 3d microfabrication[J]. Science, 2002, 296(5570): 1106-1109. doi: 10.1126/science.296.5570.1106 [5] Cumpston B H, Ananthavel S P, Barlow S, et al. Two-photon polymerization initiators for three-dimensional optical data storage and microfabrication[J]. Nature, 1999, 398(6722): 51-54. doi: 10.1038/17989 [6] Serbin J, Ovsianikov A, Chichkov B. Fabrication of woodpile structures by two-photon polymerization and investigation of their optical properties[J]. Optics Express, 2004, 12(21): 5221-5228. doi: 10.1364/OPEX.12.005221 [7] Serbin J, Egbert A, Ostendorf A, et al. Femtosecond laser-induced two-photon polymerization of inorganic-organic hybrid materials for applications in photonics[J]. Optics Letters, 2003, 28(5): 301-303. doi: 10.1364/OL.28.000301 [8] Peltola S M, Melchels F P W, Grijpma D W, et al. A review of rapid prototyping techniques for tissue engineering purposes[J]. Annals of Medicine, 2008, 40(4): 268-280. doi: 10.1080/07853890701881788 [9] Ma H, Jen A K Y, Dalton L R. Polymer-based optical waveguides: Materials, processing, and devices[J]. Advanced Materials, 2002, 14(19): 1339-1365. doi: 10.1002/1521-4095(20021002)14:19<1339::AID-ADMA1339>3.0.CO;2-O [10] Luo Xiangang. Principles of electromagnetic waves in metasurfaces[J]. Science China Physics, Mechanics & Astronomy, 2015, 58(9): 594201. [11] Luo Xiangang, Pu Mingbo, Ma Xiaoliang, et al. Taming the electromagnetic boundaries via metasurfaces: from theory and fabrication to functional devices[J]. International Journal of Antennas and Propagation, 2015, 2015: 204127. [12] Raymo F M. Digital processing and communication with molecular switches[J]. Advanced Materials, 2002, 14(6): 401-414. doi: 10.1002/(ISSN)1521-4095 [13] Zhang Xian, Yu Xiaoqiang, Sun Yuming, et al. Synthesis, structure and nonlinear optical properties of two new one and two-branch two-photon polymerization initiators[J]. Chemical Physics, 2006, 328(1-3): 103-110. doi: 10.1016/j.chemphys.2006.06.024 [14] Hoffman G S, Weyand C M, Langford C A, et al. Inflammatory diseases of blood vessels[M]. Oxford: Wiley-Blackwell, 2012. [15] Taylor J J, Memmler R L, Cohen B J. Memmler's structure and function of the human body[M]. Philadelphia: Lippincott Williams & Wilkins, 2005. [16] Wuyts F L, Vanhuyse V J, Langewouters G J, et al. Elastic properties of human aortas in relation to age and atherosclerosis: a structural model[J]. Physics in Medicine and Biology, 1995, 40(10): 1577-1597. doi: 10.1088/0031-9155/40/10/002 [17] Rico F, Roca-Cusachs P, Gavara N, et al. Probing mechanical properties of living cells by atomic force microscopy with blunted pyramidal cantilever tips[J]. Physical Review E, 2005, 72(2): 021914. doi: 10.1103/PhysRevE.72.021914 [18] Wachtman J B, Cannon W R, Matthewson M J. Mechanical properties of ceramics[M]. 2nd ed. Hoboken, NJ: John Wiley & Sons, 2009. [19] Quaresimin M, Bertani R, Zappalorto M, et al. Multifunctional polymer nanocomposites with enhanced mechanical and anti-microbial properties[J]. Composites Part B, 2015, 80: 108-115. doi: 10.1016/j.compositesb.2015.05.027 [20] Zhang Qingxin, Yu Zhongzhen, Xie Xiaolin, et al. Crystallization and impact energy of polypropylene/CaCO3 nanocomposites with nonionic modifier[J]. Polymer, 2004, 45(17): 5985-5994. doi: 10.1016/j.polymer.2004.06.044 [21] Huo Qisheng, Zhao Dongyuan, Feng Jianglin, et al. Room temperature growth of mesoporous silica fibers: a new high-surface-area optical waveguide[J]. Advanced Materials, 1997, 9(12): 974-978. doi: 10.1002/adma.v9:12 [22] Chen Lianwei, Zheng Xiaorui, Du Zheren, et al. A frozen matrix hybrid optical nonlinear system enhanced by a particle lens[J]. Nanoscale, 2015, 7(36): 14982-14988. doi: 10.1039/C5NR03304G [23] Zhou Y, Chen L W, Du Z R, et al. Tunable optical nonlinearity of silicon nanoparticles in solid state organic matrix[J]. Optical Materials Express, 2015, 5(7): 1606-1612. doi: 10.1364/OME.5.001606 [24] Pu Mingbo, Li Xiong, Ma Xiaoliang, et al. Catenary optics for achromatic generation of perfect optical angular momentum[J]. Science Advances, 2015, 1(9): e1500396. [25] Li Xiong, Pu Mingbo, Zhao Zeyu, et al. Catenary nanostructures as compact Bessel beam generators[J]. Scientific Reports, 2016, 6: 20524. doi: 10.1038/srep20524 [26] Luo Xiangang, Ishihara T. Surface plasmon resonant interference nanolithography technique[J]. Applied Physics Letters, 2004, 84(23): 4780-4782. doi: 10.1063/1.1760221 [27] Feng Qin, Pu Mingbo, Hu Chenggang, et al. Engineering the dispersion of metamaterial surface for broadband infrared absorption[J]. Optics Letters, 2012, 37(11): 2133-2135. doi: 10.1364/OL.37.002133 [28] Pu Mingbo, Zhao Zeyu, Wang Yanqin, et al. Spatially and spectrally engineered spin-orbit interaction for achromatic virtual shaping[J]. Scientific Reports, 2015, 5: 9822. doi: 10.1038/srep09822 [29] Luo Xiangang, Yan Lianshan. Surface plasmon polaritons and its applications[J]. IEEE Photonics Journal, 2012, 4(2): 590-595. doi: 10.1109/JPHOT.2012.2189436 [30] Infuehr R, Pucher N, Heller C, et al. Functional polymers by two-photon 3D lithography[J]. Applied Surface Science, 2007, 254(4): 836-840. doi: 10.1016/j.apsusc.2007.08.011 [31] Parker S T, Domachuk P, Amsden J, et al. Biocompatible silk printed optical waveguides[J]. Advanced Materials, 2009, 21(23): 2411-2415. doi: 10.1002/adma.v21:23 -

Overview

Abstract:Arbitrary micro-scale three-dimensional (3D) structures fabrication is a dream to achieve many exciting goals that have been persuaded for a long time. Among all these applications, the direct 3D printing to fabricate human organs and integrated photonic circuits are extraordinarily attractive as they can promote the current technology to a new level. Among all the 3D printing methods available, two-photon polymerization (2PP) is very competitive as it is a unique method to achieve sub-micron resolution to make any desired tiny true 3D structures. To achieve it, 2PP relies on the direct laser writing to transfer the pattern into the photoresist material by the two photon absorption to initialize the in-situ polymerization. However, the requirements for the building blocks are different for different purposes. Even though 2PP is of many superior properties, it is often considered as a supporting role to make the initial polymer structural molds or backbones for further processing steps. The reason is that the photoresist used in 2PP lacks the proper material properties to act as the functional materials in different applications. To realize it, it is the key to study how to make the photo-resist controllable according to different demands. In this paper, we presented one hybrid method to modify the mechanical strength and light trapping efficiency of the photoresist, which transfers the photoresist into the micro-concretes. Compared with other lithographic technologies, our approach is more favorable since the fabrication is fast. Hence, it is more suitable for scalable production. Specifically, the 2PP process is adapted to directly process three hybrid composites with different functionalities: 1) ±22% strength modification is realized in experiment via a silica nano-particles doping, which can be used to achieve tunable mechanical strength for bio-structure construction; 2) the structures doped with gold nano-particles show tunable plasmonic absorption to be used in light trapping sensors; 3) dye doped hybrid structure shows great potentials to fabricate 3D micro-chip laser. These three specific works serve as good examples to demonstrate that the hybrid 2PP method can be introduced as a unique and powerful 3D nano-printing technique for massive scale effective fabrications to make the key functional components for many unique applications.

-

Access History

-

Figure 1.

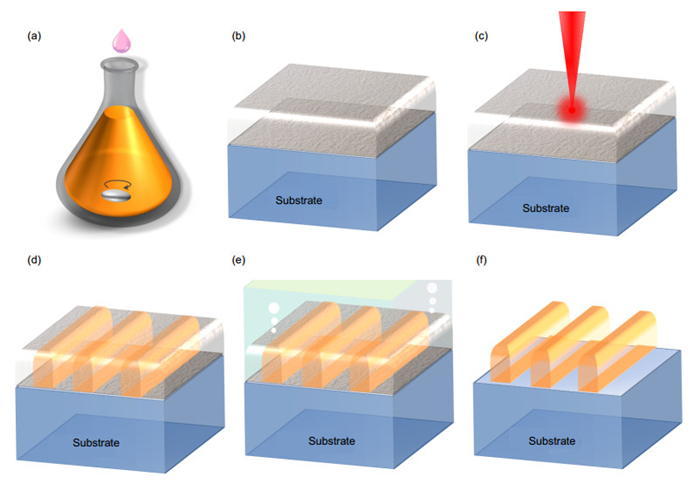

Process flow of two-photon polymerization. (a) Photoresist preparation. (b) Photoresist coating. (c) Laser exposure. (d) Pre-develop treatment. (e) Photoresist develop. (f) Post-develop treatment.

-

Figure 2.

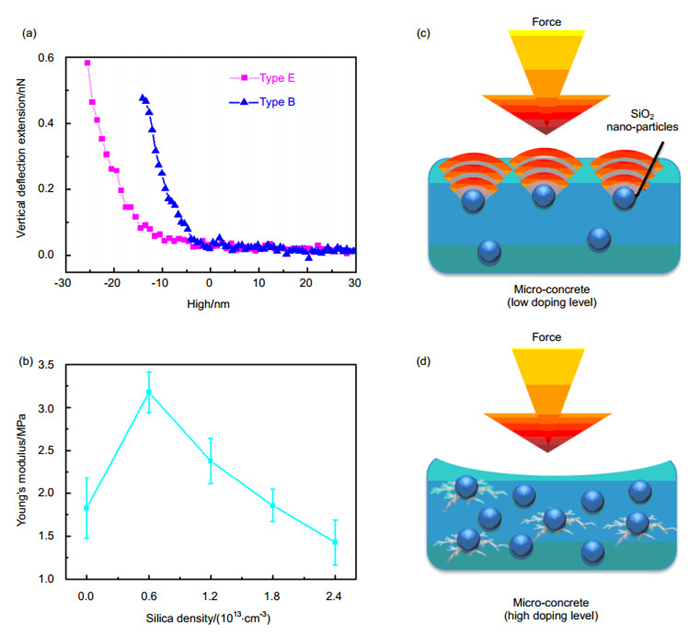

(a) AFM contact mode results for the mechanical property measurement. (b) Young's modulus values measured from 2PP microstructures fabricated from non-doped and doped photoresists. Type A: no dopants; Type B, C, D, E are doped with silica nano-particles at a concentration of 0.6×1013 cm-3, 1.2×1013 cm-3, 1.8×1013 cm-3 and 2.4×1013 cm-3, respectively. Mechanical behaviors of the micro-concretes when doped with (c) low and (d) high concentrations of silica nano-particles.

-

Figure 3.

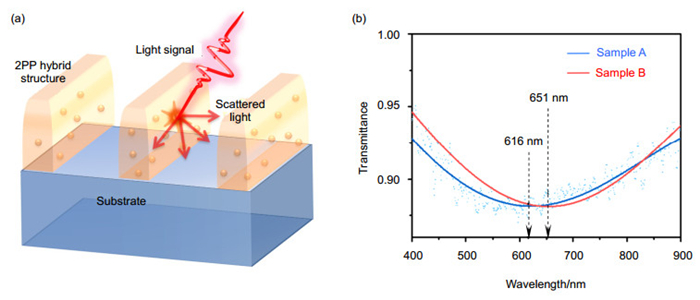

(a) Schematic diagram of light trapping structure doped with gold nano-particles. (b) Transmittance spectra of the samples doped with gold nano-particles at various sizes.

-

Figure 4.

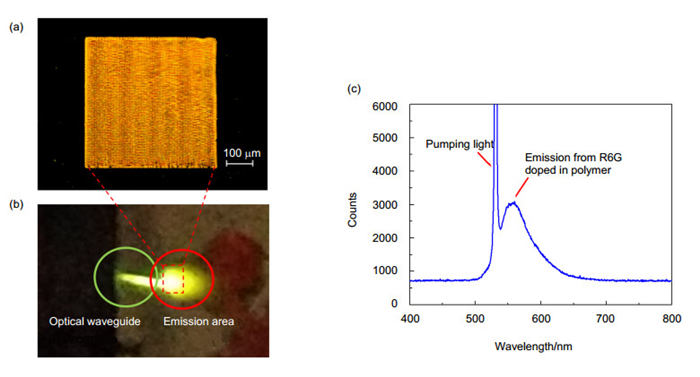

(a) Optical image of fishnet structure. (b) Optical image of the light emission material pumped with a 532 nm laser. (c) Emission spectrum of the light emission source doped with R6G.

E-mail Alert

E-mail Alert RSS

RSS

DownLoad:

DownLoad: