-

Abstract:

Paint removal from steel structure is executed for shipyards of marine and offshore engineering. Due to environmental unfriendliness and unhealthy drawbacks of sand blasting technique, laser ablation technique is proposed as a substituting method. By absorbing high energy of the 1064 nm pulsed laser, the paint is vaporized quickly. The ablated debris is then collected by using a suction pump. Initial metal surface of the steel is exposed when laser beam irradiates perpendicularly and scans over it. The cleaned surface fulfills the requirements of surface preparation standards ISO 8501 of SA2. The adhesion is further characterized with pull-off test after carrying out painting with Jotamastic 87 aluminum paint. The repainting can be embedded onto the laser cleaned surface to bond much more tightly. The excellent adhesion strength of 20 MPa between repainted coating and the substrate is achieved, which is higher than what is required by shipyards applications.

-

Key words:

- laser /

- steel structure surface /

- paint removal /

- repainting adhesion

-

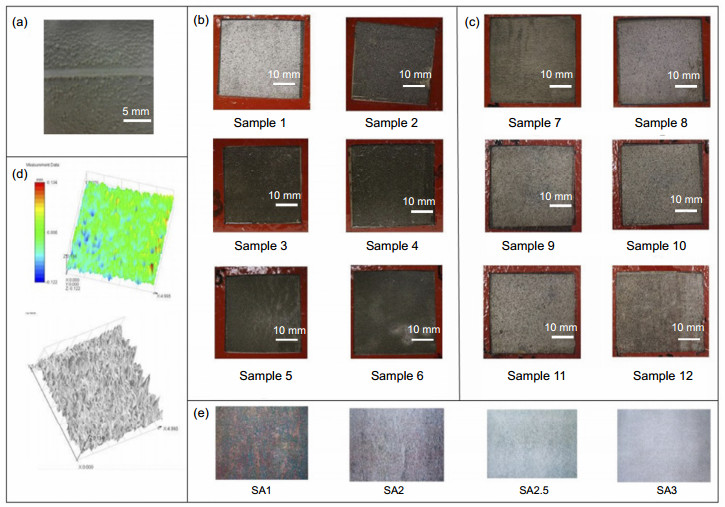

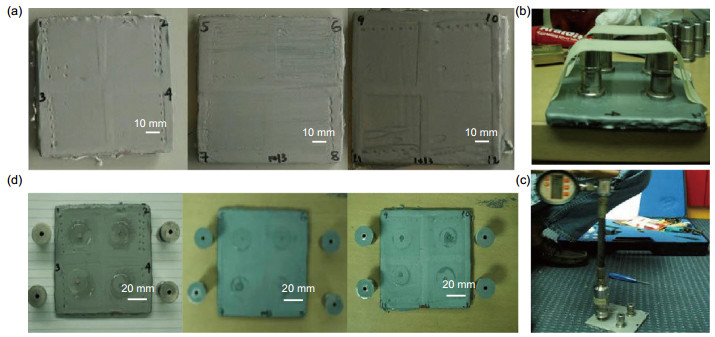

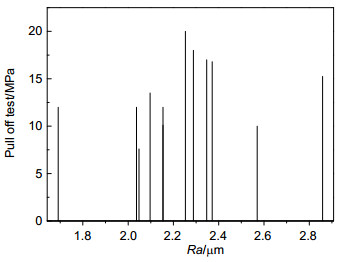

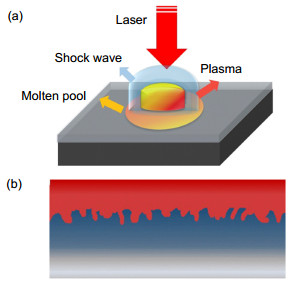

Abstract:Laser ablation has been widely applied to clean metal surface artefacts, microelectronics and nuclear decontamination. In shipyards, paint removal is conventionally done with sand blasting, which is an environmentally unfriendly as fine grit particles used during sand blasting are difficult to be cleaned away. Meanwhile, unhealthy problems of sand blasting affect workers' health. Laser ablation is proposed as a substituting method. In this work, laser removal of paint on steel is executed for shipyards of marine and offshore engineering. Nd:YAG pulse laser with wavelength 1064 nm can efficiently remove the paint and does not damage the substrate after scanning triple times. With the 100 ns pulse width, the temperature rises in a very short time and results in partial material vaporized quickly from the surface. A suction pump is set beside the substrate to absorb the ablated debris. By comparing with the ISO 8501 standards, preparation of steel substrates before the applications of paints and related products, the cleaned surface achieves ISO 8501 standard SA2. The liner roughness Ra and three dimensional roughness Sa of the laser cleaned surface are measured to be in a range from 1.691 μm to 2.859 μm and 0.019 mm to 0.043 mm, respectively. The painting is carried out with Jotamastic 87 aluminium paint, which can be used in marine for outside surfaces of hulls. The repaint is cured in room temperature and pressure for one day before leaving it in an oven for three days at 105. ℃ The adhesion test is performed according to ISO 4624 pull-off test. The evaluation of the tests is based on the percentage of dolly removed paint area. With the textured morphologies of tiny pores, holes and voids created by laser ablation, the paint spreads and solidifies into these microstructures and forms the mechanical bond. The repaint is embedded onto the rough surface to bond much more tightly. The excellent adhesion strength of 20 MPa between repaint and the substrate is achieved and even the lowest adhesion of 7.6 MPa is much higher than the standard of 3 MPa set for ship hull.

-

-

Table 1. Three sets of laser parameters for paint removal.

Pass No. Average power/W Repetition rate/kHz Fluence/(J/cm2) Scan speed/(mm/s) 1 10 15 8.5 50 2 5 30 2.1 150 3 10 15 8.5 150 Table 2. Roughness and pull-off test results for double scan samples.

Sample Ave. dry film thickness/pm Ave. Ra/pm Sa/mm Pull-off test/MPa 1 457 2.048 0.020 7.60 2 385 2.154 0.022 10.10 3 419 2.097 0.021 13.50 4 303 2.570 0.021 10.00 5 331 2.253 0.020 20.00 6 336 2.288 0.021 18.00 7 261 1.691 0.020 12.00 8 343 2.037 0.019 12.00 9 235 2.371 0.043 16.80 10 244 2.154 0.031 12.00 11 288 2.347 0.024 17.00 12 290 2.859 0.024 15.25 -

[1] Turner A. Marine pollution from antifouling paint particles[J]. Marine Pollution Bulletin, 2010, 60(2): 159–171. doi: 10.1016/j.marpolbul.2009.12.004

[2] Pini R, Siano S, Salimbeni R, et al. Tests of laser cleaning on archeological metal artefacts[J]. Journal of Cultural Heritage, 2000, 1(Suppl 1): S129-S137. https://www.sciencedirect.com/science/article/pii/S1296207400001394

[3] Lee J M, Watkins K G. Laser removal of oxides and particles from copper surfaces for microelectronic fabrication[J]. Optics Express, 2000, 7(2): 68–76. doi: 10.1364/OE.7.000068

[4] Delaporte P, Gastaud M, Marine W, et al. Dry excimer laser cleaning applied to nuclear decontamination[J]. Applied Surface Science, 2003, 208–209: 298–305. https://www.sciencedirect.com/science/article/pii/S0169433202013600

[5] Guo H, Martukanitz R, DebRoy T. Laser assisted cleaning of oxide films on SUS409 stainless steel[J]. Journal of Laser Applications, 2004, 16(4): 236–244. doi: 10.2351/1.1809639

[6] Kumar A, Sonar V R, Das D K, et al. Laser cleaning of tungsten ribbon[J]. Applied Surface Science, 2014, 308: 216–220. doi: 10.1016/j.apsusc.2014.04.138

[7] Kumar A, Bhatt R B, Behere P G, et al. Laser-assisted surface cleaning of metallic components[J]. Pramana, 2014, 82(2): 237–242. doi: 10.1007/s12043-013-0665-6

[8] Leone C, Genna S, Caggiano A. Compact disc laser cleaning for polycarbonate recovering[J]. Procedia CIRP, 2013, 9: 73–78. doi: 10.1016/j.procir.2013.06.171

[9] Georgiou S. Laser cleaning methodologies of polymer substrates[M]//Lippert T K. Polymers and Light. Berlin Heidelberg: Springer, 2004, 168: 1–49.

[10] Gaspard S, Oujja M, Moreno P, et al. Interaction of femtosecond laser pulses with tempera paints[J]. Applied Surface Science, 2008, 255(5): 2675–2681. doi: 10.1016/j.apsusc.2008.07.205

[11] Novikov B Y, Chikalev Y V, Shakhno E A. Laser assisted graffiti paints removing[J]. Proceedings of SPIE, 2011, 7996: 799616. https://www.spiedigitallibrary.org/redirect/proceedings/proceeding?doi=10.1117/12.887724

[12] Madhukar Y K, Mullick S, Shukla D K, et al. Effect of laser operating mode in paint removal with a fiber laser[J]. Applied Surface Science, 2013, 264: 892–901. doi: 10.1016/j.apsusc.2012.10.193

[13] Chen G X, Kwee T J, Tan K P, et al. Laser cleaning of steel for paint removal[J]. Applied Physics A, 2010, 101(2): 249–253. doi: 10.1007/s00339-010-5811-0

[14] Eklund B, Johansson L, Ytreberg E. Contamination of a boatyard for maintenance of pleasure boats[J]. Journal of Soils and Sediments, 2014, 14(5): 955–967. doi: 10.1007/s11368-013-0828-6

[15] Turner A, Comber S, Rees A B, et al. Metals in boat paint fragments from slipways, repair facilities and abandoned vessels: an evaluation using field portable XRF[J]. Talanta, 2015, 131: 372–378. doi: 10.1016/j.talanta.2014.08.012

[16] Brygo F, Dutouquet C, Le Guern F, et al. Laser fluence, repetition rate and pulse duration effects on paint ablation[J]. Applied Surface Science, 2006, 252(6): 2131–2138. doi: 10.1016/j.apsusc.2005.02.143

[17] Jotun. Technical Data sheet of Jotamastic 87 Aluminiun [EB/OL]. http://jotun-spb.ru/en/jotamastic-87-aluminium.

[18] General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Antifouling and anticorrosive paint systems for ship hull: GB/T 6822–2014[S]. Beijing: China Standard Press, 2014 (in Chinese).

[19] Singh S C, Zeng Haibo, Yang Shikuan, et al. Nanomaterials: laser‐based processing in liquid media[M]//Singh S C, Zeng Haibo, Guo Chunlei, et al. Nanomaterials: Processing and Characterization with Lasers. Weinheim, Germany: Wiley-VCH Verlag & Co. KGaA, 2012: 317–494.

[20] Tang M, Shim V, Pan Z, et al. Laser ablation of metal substrates for super-hydrophobic effect[J]. Journal of Laser Micro/ Nanoengineering, 2011, 6(1): 6–9. http://www.mendeley.com/catalog/laser-ablation-metal-substrates-superhydrophobic-effect/

[21] Lu Y F, Song W D, Hong M H, et al. Laser removal of particles from magnetic head sliders[J]. Journal of Applied Physics, 1996, 80(1): 499–504. doi: 10.1063/1.362754

[22] Zhu S, Lu Y F, Hong M H, et al. Laser ablation of solid substrates in water and ambient air[J]. Journal of Applied Physics, 2001, 89(4): 2400–2403. doi: 10.1063/1.1342200

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: