-

摘要:

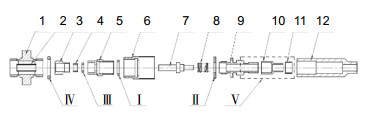

针对高功率光纤激光系统中光纤对接端面产生水雾凝结的问题,分析出产生该问题最重要因素为连接器不具备防潮密封性能,对其结构装配及使用过程进行剖析,同时指出其防潮密封缺陷原因,进行技术创新与工艺改进,设计了防潮密封型光纤连接器。介绍了该新型连接器防潮密封原理及结构组成;重点对该新型光纤连接器性能进行全面测试,包括浸水试验、恒定湿热试验、在线运行应用验证等。试验结果表明,其插入损耗小于0.2 dB,防潮密封性能良好,取得较好的预期效果。

Abstract:

Abstract:Aiming at the problem of water mist condensation on the fiber end face in a high-power fiber laser system, the most important factor causing this problem is that the traditional optical fiber connector does not have the moisture-proof sealing performance. The connector structure assembly and use process are analyzed in-depth, and the causes of the moisture-proof seal defects are pointed out. Through technological innovation and process improvement, a moisture-proof seal fiber connector is designed and completed. The principle and structure of the moisture-proof seal of the new connector are introduced. The main performances of the new connector are tested comprehensively, including immersion test, constant damp heat test, online application test. The experimental results show that the new connector has a better moisture-proof seal with IL less than 0.2 dB.

-

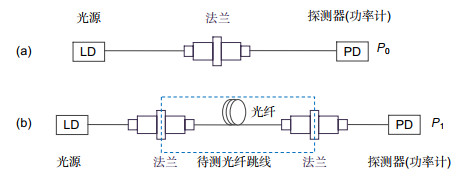

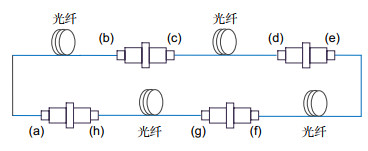

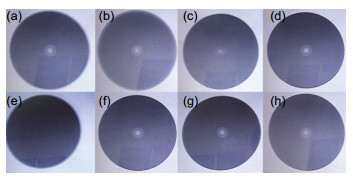

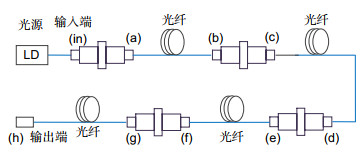

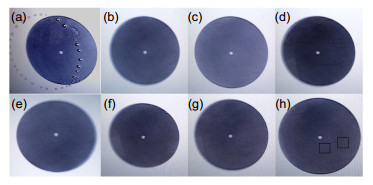

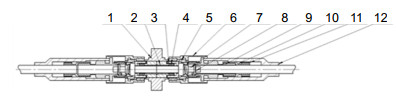

Overview: In the application of high-power laser optical fiber transmission and measurement, the transmission power of optical fiber is higher. With the laser disconnected, the ceramic insert core is cooled, and the water vapor in the air will condense at the end face of the connector. It will increase the fiber splicing loss and even damage the fiber end face. It is necessary to fundamentally solve the problem of water mist condensation on the end face of the connector. The most important factor of water mist condensation is that the traditional optical fiber connector does not have moisture-proof sealing performance. This paper analyzes the structure assembly and use process of the connector, and points out five defects of the moisture-proof seal. Specifically, there is no sealing process or moisture-proof sealing treatment in the assembly process. In addition, when the connector is used for the butt joint with flange, no moisture-proof sealing process has been carried out. It causes the dust and water vapor in the air to enter the surrounding and end face of the ceramic insert core. So, the internal humidity and cleanliness of the connector are not up to standard, which brings serious consequences to the field of optical transmission and optical measurement. Through technological innovation and process improvement, a new moisture-proof seal fiber connector is designed and completed without changing the original structure and size of the optical fiber connector. The principle and structure of the moisture-proof seal of the new connector are introduced. The main performances of the new connector are tested comprehensively, including the main optical performance test, immersion test, constant damp heat test, and online application test. The experimental results show that the new connector has better moisture-proof seal with IL less than 0.2 dB. After immersion test, the insertion loss index of the connector also meets the expected requirements. The main optical parameters meet the application requirements. The new moisture-proof sealing connector solves the problem of water mist condensation on the end face of the connector, and can be used in high power fiber laser system for a mid-long term, that will have good prospects. In the next step, we will continue to innovate and introduce this innovative technology and improved process into the single polarization fiber connector and the polarization-maintaining fiber connector. We will design and complete the moisture-proof sealing single-polarization optical fiber connector and moisture-proof sealing polarization-maintaining fiber connector to meet the new application requirements of the fiber laser system.

-

-

表 1 测试使用仪器设备及环境条件

Table 1. Test instruments and environmental conditions

测试条件 参数 光源 功率/dBm 10.31 波长/nm 1053 功率计 PM121D (数字表头、带光电探头) 待测跳线 G.652光纤ϕ3.0 mm单芯(1 m)防潮密封 测试温度 23.5 ℃(室温) 相对湿度/% 50 表 2 防潮密封型光纤跳线IL测量结果

Table 2. IL of moisture-proof seal fiber connector

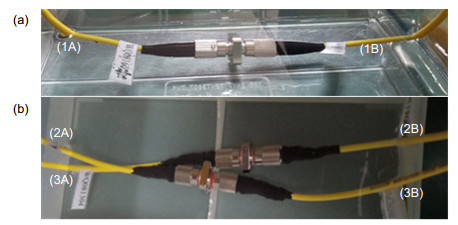

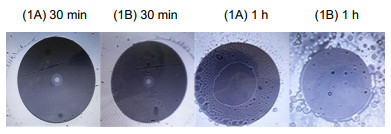

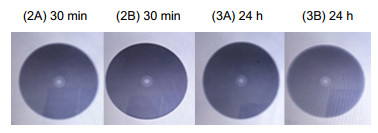

dB 序号 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 IL 0.06 0.09 0.12 0.08 0.14 0.11 0.07 0.09 0.08 0.17 0.15 0.07 0.06 0.15 0.16 0.10 0.19 0.11 0.09 0.08 - 表 3 浸水试验后跳线IL测量结果

Table 3. Fiber connector IL after immersion test

跳线及试验时间 插损值/(dB) 普通跳线(1A), (1B)、浸水30 min 0.93 普通跳线(1A), (1B)、浸水1 h 2.35 新工艺跳线(2A), (2B)、浸水30 min 0.09 新工艺跳线(3A), (3B)、浸水24 h 0.11 -

[1] 童维军, 杨晨, 刘彤庆, 等.光纤传感用新型特种光纤的研究进展与展望[J].光电工程, 2018, 45(9): 180243. doi: 10.12086/oee.2018.180243

Tong W J, Yang C, Liu T Q, et al. Progress and prospect of novel specialty fibers for fiber optic sensing[J]. Opto-Electronic Engineering, 2018, 45(9): 180243. doi: 10.12086/oee.2018.180243

[2] 孙志红, 李平, 赵润昌, 等.高功率激光装置打靶精度测试技术[J].强激光与粒子束, 2011, 23(8): 2121-2124. doi: 10.3788/HPLPB20112308.2121

Sun Z H, Li P, Zhao R C, et al. Technology of target positioning precision measurement of high power laser system[J]. High Power Laser and Particle Beams, 2011, 23(8): 2121-2124. doi: 10.3788/HPLPB20112308.2121

[3] 朱莉, 徐胜勇.基于OpenCV的光纤端面检测系统研究[J].光通信研究, 2015(1): 28-30, 38. doi: 10.13756/j.gtxyj.2015.01.010

Zhu L, Xu S Y. Research on an OpenCV-based optical fiber end detection system[J]. Study on Optical Communications, 2015(1): 28-30, 38. doi: 10.13756/j.gtxyj.2015.01.010

[4] Xu Y X, Zhu R H, Chen L. Measurement of apex offsets for fiber connector end faces[J]. Semiconductor Photonics and Technology, 2006, 12(4): 270-275. doi: 10.1016/S1002-0160(06)60023-4

[5] 伏燕军, 邹文栋, 肖慧荣, 等.光纤连接器端面检测技术的研究[J].激光杂志, 2005, 26(3): 70-71. doi: 10.3969/j.issn.0253-2743.2005.03.032

Fu Y J, Zou W D, Xiao H R, et al. The research of measuring technology for fiber connector endface[J]. Laser Journal, 2005, 26(3): 70-71. doi: 10.3969/j.issn.0253-2743.2005.03.032

[6] 黄欢, 孙博, 曾声奎, 等.光纤连接器的应用环境条件和失效机理分析[J].机电元件, 2012, 32(2): 32-39. doi: 10.3969/j.issn.1000-6133.2012.02.009

Huang H, Sun B, Zeng S K, et al. Typical application environmental conditions and failure mechanisms analysis of fiber optic connectors[J]. Electromechanical Components, 2012, 32(2): 32-39. doi: 10.3969/j.issn.1000-6133.2012.02.009

[7] 李华强.军用光纤连接器技术近期发展动向[J].光通信技术, 2015, 39(3): 21-23. doi: 10.13921/j.cnki.issn1002-5561.2015.03.007

Li H Q. Recent trend of military optical fiber connector technology[J]. Optical Communication Technology, 2015, 39(3): 21-23. doi: 10.13921/j.cnki.issn1002-5561.2015.03.007

[8] Duan J A, Liu D F, Zhong J. Influences of polishing on return loss of optical fiber connectors[J]. Journal of Central South University of Technology, 2005, 12(3): 320-323. doi: 10.1007/s11771-005-0153-3

[9] 黄蓓.光纤连接器使用操作规范探讨[J].电子产品可靠性与环境试验, 2011, 29(5): 48-52. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKH201106010.htm

Huang B. Handling and operation rules of optical fiber connectors[J]. Electronic Product Reliability and Environmental Testing, 2011, 29(5): 48-52. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKH201106010.htm

[10] Horwitz D. COTS fiber optic connectors for harsh environments[C]//The Optical Fiber Communication Conference 2000, Baltimore, 2000: 3.

[11] 刘君文, 何兴道.光纤连接器制作中的端面处理技术[J].光纤与电缆及其应用技术, 2007(3): 22-25. doi: 10.3969/j.issn.1006-1908.2007.03.007

Liu J W, He X D. Endface treatment technology in fabrication of fiber optic connector[J]. Optical Fiber & Electric Cable, 2007(3): 22-25. doi: 10.3969/j.issn.1006-1908.2007.03.007

[12] 李华强, 黄媛媛, 李太华, 等.大功率光纤连接器插损测试技术研究[J].光通信技术, 2010, 34(2): 46-48. doi: 10.3969/j.issn.1002-5561.2010.02.015

Li H Q, Huang Y Y, Li T H, et al. Research on the inserting loss of fiber connector with high power[J]. Optical Communication Technology, 2010, 34(2): 46-48. doi: 10.3969/j.issn.1002-5561.2010.02.015

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: