Layout-stiffness-correction force joint optimization of support system for ultra-large thin meniscus mirror

-

摘要:

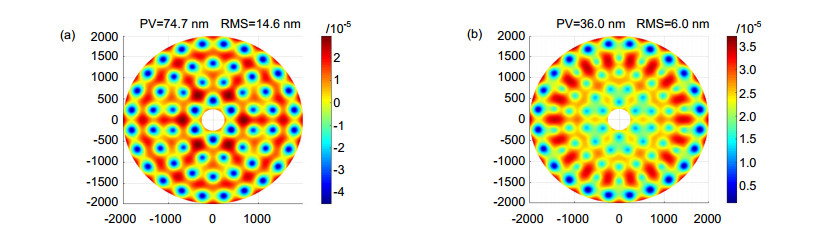

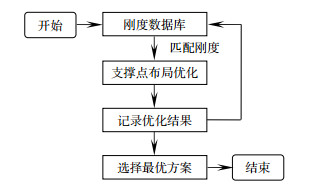

在超大口径原位加工与检测中,目前多采用被动式Whiffletree液压支撑系统(原位支撑),而该类支撑单元的轴向刚度存在较大差异性,会显著影响轻薄型反射镜的面形精度。为解决这一问题,研究了主动型原位支撑的支点布局、单元刚度和主动校正力的联合优化方法。首先,针对支撑单元刚度差异,提出了支撑刚度、支点位置的分级布局优化方法,获得了支撑系统的初始优化解; 其次,结合模式定标法和最小二乘法,进行了支撑点主动力校正,以获得支撑面形的最终优化解; 最后,结合具体案例的数字仿真试验,验证了方法的有效性。结果表明:对于4 m弯月型轻薄反射镜,仅被动支撑下,分级布局优化后,60点方案面形精度RMS值由150.6 nm减少到32.9 nm,78点方案面形精度RMS值由45.2 nm减少到22.6 nm,优化效果显著; 进一步经主动校正后,60点方案和78点方案面形精度RMS值分别为14.6 nm和6.9 nm,均满足面形精度RMS值小于λ/40(λ=632.8 nm)的指标要求; 最终选取60点轴向支撑方案。通过对支点布局、支撑刚度和校正力进行联合优化,可以大幅增加原位支撑系统的适用性、灵活性,降低实施难度。

-

关键词:

- 布局优化 /

- 主动光学 /

- 液压Whiffletree /

- 刚度差异 /

- 原位支撑

Abstract:Passive hydraulic support units (PHSUs) are frequently used in the in-situ fabrication and testing (in-situ support). However, the difference in PHSUs' stiffness will affect the mirror surface figure, especially for those thin meniscus mirrors. In order to solve this problem, the joint optimization method of layout, stiffness and active correction is studied. Firstly, for the difference of PHUS' stiffness, a hierarchical layout optimization method for support stiffness and support position is proposed to obtain the initial optimization solution of the support system. Then, the mode calibration method and the least square method is used for active correction of support system to obtain the final optimized solution of the mirror surface figure. Finally, the effectiveness of the method is verified by a numerical simulation experiment with specific cases. The results show that, for 4 m thin meniscus mirror, after layout optimization, with the hydraulic passive support system, the root mean square (RMS) of the mirror surface errors of 60 point axial support system is reduced from 150.6 nm to 32.9 nm, and the RMS value of the mirror surface errors of 78 point axial support system is reduced from 45.2 nm to 22.6 nm. The optimization effect is remarkable. After active correction, the RMS value of the mirror surface errors of 60 point axial support system is 14.6 nm, and it is 6.9 nm for 78 point axial support system. The requirement of the RMS value of the mirror surface error is less than λ/40 (λ=632.8 nm). The support systems meet the requirement. Finally, the 60 point axial support system was selected. Through the joint optimization of layout, stiffness and active correction for supporting points, it can greatly increase the applicability, flexibility and reduce the difficulty of implementation for the in-situ support system.

-

Key words:

- layout optimization /

- active optics /

- hydraulic Whiffletree /

- stiffness difference /

- in-situ support

-

Overview: With the increasing requirements for the sensitivity, resolution and angle of view of space telescopes, the aperture of space mirror are getting bigger and bigger, which greatly increases the difficulty of mirror fabrication support. For the space mirror in the in-situ fabrication and testing, besides the influence of other factors such as temperature, the self-weight deformation has a great influence on mirror surface figure. And the larger the aperture and the higher the precision, the more difficult the support is. The self-weight deformation is mainly affected by factors such as the number of support points, the position of the support points and the stiffness of the support unit. Passive hydraulic support units (PHSUs) are frequently used in the in-situ fabrication and testing. However, some studies have found that the number of supporting units of large-aperture mirrors is too large, resulting in a large difference in the stiffness of each group of hydraulic support units, and has a great influence on mirror surface figure. It has become a hidden danger affecting the accuracy of in-situ fabrication and testing. In order to reduce the number of supporting units and increase the accuracy of the supporting surface, the joint optimization method of layout, stiffness and active correction is studied. Firstly, for the difference of PHUS' stiffness, a hierarchical layout optimization method for support stiffness and support position is proposed to obtain the initial optimization solution of the support system. Then, the mode calibration method and the least square method is used for active correction of support system to obtain the final optimized solution of the mirror surface figure. Finally, the effectiveness of the method is verified by a numerical simulation experiment with specific cases. The results show that, for 4 m thin meniscus mirror, after layout optimization, with the hydraulic passive support system, the root mean square (RMS) of the mirror surface errors of 60 point axial support system is reduced from 150.6 nm to 32.9 nm, and the RMS value of the mirror surface errors of 78 point axial support system is reduced from 45.2 nm to 22.6 nm. The optimization effect is remarkable. After active correction, the RMS value of the mirror surface errors of 60 point axial support system is 14.6 nm, and it is 6.9 nm for 78 point axial support system. The requirement of the RMS value of the mirror surface error is less than λ/40 (λ=632.8 nm). The support systems meet the requirement. Finally, the 60 point axial support system was selected. Through the joint optimization of layout, stiffness and active correction for supporting points, it can greatly increase the applicability, flexibility and reduce the difficulty of implementation for the in-situ support system.

-

-

表 1 各支撑方案自重变形下面形精度

Table 1. The mirror surface RMS values of each support system from the gravity

Support points 60 66 78 84 RMS/nm 78.3 74.1 39.3 39.2 表 2 60点轴向支撑系统布局优化结果

Table 2. Results of layout optimization for 60 point axial support system

60points K1/(N/mm) K2/(N/mm) K3/(N/mm) K4/(N/mm) R1/mm R2/mm R3/mm R4/mm PV/nm RMS/nm Before 2002 1918 1978 1935 465 910 1315 1780 633.0 150.6 After 1978 1918 2002 1890 471 921 1355 1818 169.0 32.9 表 3 78点轴向支撑系统布局优化结果

Table 3. Results of layout optimization for 78 point axial support system

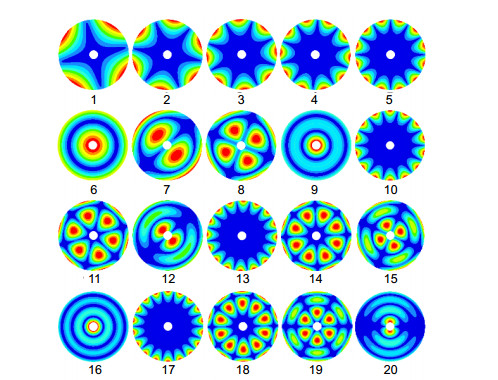

78 points K1/(N/mm) K2/(N/mm) K3/(N/mm) K4/(N/mm) K5/(N/mm) R1/mm R2/mm R3/mm R4/mm R5/mm PV/nm RMS/nm Before 1890 2002 1918 1978 1935 425 775 1125 1475 1825 300.0 45.2 After 1935 1978 2002 1918 1890 412 756 1135 1468 1826 120.6 22.6 表 4 60点支撑方案模式定标计算结果

Table 4. Results of mode calibration for 60 point axial support system

Mode F1max/N F2max/N F3max/N F4max/N SRMS/nm 1 -0.5 1.3 -3.2 5.6 1000 2 -0.2 -2.1 5.9 15.5 1000 3 0.1 -3.1 -14.5 40.1 999 4 -0.04 -4.2 -27.2 90.4 1000 5 0.007 4.7 -39.0 -126.6 1000 6 1221.0 693.85 66.9 -701.9 999 7 185.8 233.5 117.9 -137.4 999 8 -156.2 257.0 -180.2 115.51 999 9 -305.6 69.4 181.9 -94.1 999 10 -0.2 4.2 69.8 -312.9 1000 11 48.7 341.2 376.7 -148.7 1000 12 -609.3 163.4 392.8 -136.8 999 13 -0.08 -3.33 94.7 492.5 999 14 21.3 -74.7 -646.8 200.4 999 15 708.1 -510.3 614.5 -179.8 999 16 502.3 -705.9 436.0 -99.1 999 17 -0.6 1.7 124.2 723.5 1000 18 -7.5 -438.9 1080.0 -268.2 1000 19 625.2 934.3 -741.2 -147.4 999 20 -1578.0 1157.3 -506.9 -91.1 999 -

[1] 张珑, 叶璐, 张金平, 等. 1.2m轻量化空间反射镜的重力支撑变形分离[J].光子学报, 2018, 47(7): 0722002. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gzxb201807010

Zhang L, Ye L, Zhang J P, et al. Gravity and support error separation of 1.2 m lightweight space mirror[J]. Acta Photonica Sinica, 2018, 47(7): 0722002. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gzxb201807010

[2] 柳鸣, 张立中, 李响, 等.空间轻小型反射镜柔性支撑设计与动力学分析[J].光电工程, 2018, 45(5): 170686. doi: 10.12086/oee.2018.170686

Liu M, Zhang L Z, Li X, et al. Design of flexure support of space compact reflector subassembly and dynamic analysis[J]. Opto-Electronic Engineering, 2018, 45(5): 170686. doi: 10.12086/oee.2018.170686

[3] 胡海飞, 罗霄, 辛宏伟, 等.超大口径光学制造均力支撑布局优化[J].光学学报, 2014, 34(4): 0422003. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201404035

Hu H F, Luo X, Xin H W, et al. Layout optimization of equal-force supports for ultra-large optical fabrication[J]. Acta Optica Sinica, 2014, 34(4): 0422003. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201404035

[4] 郭鹏, 张景旭, 杨飞, 等. TMT三镜缩比系统支撑点位置优化[J].激光与光电子学进展, 2015, 52(11): 112205. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jgygdzxjz201511029

Guo P, Zhang J X, Yang F, et al. Optimization of TMT M3 prototype's support points[J]. Laser & Optoelectronics Progress, 2015, 52(11): 112205. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jgygdzxjz201511029

[5] 戴晓霖.薄型主镜面形主动控制技术研究[D].北京: 中国科学院大学(中国科学院光电技术研究所), 2018.

Dai X L. Study on the active control technology of a thin primary mirror[D]. Beijing: University of Chinese Academy of Sciences (Institute of Optics and Electronics, Chinese Academy of Sciences), 2018.

[6] 李宏壮, 张振铎, 王建立, 等.基于浮动支撑的620 mm薄反射镜面形主动校正[J].光学学报, 2013, 33(5): 0511001. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201305012

Li H Z, Zhang Z D, Wang J L, et al. Active surface-profile correction of 620 mm thin-mirror based on flotation support[J]. Acta Optica Sinica, 2013, 33(5): 0511001. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201305012

[7] 朱熠, 陈涛, 王建立, 等. 1.23 m SiC主镜的本征模式主动光学校正[J].光学 精密工程, 2017, 25(10): 2551-2563. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201710003

Zhu Y, Chen T, Wang J L, et al. Active correction of 1.23 m SiC mirror using bending mode[J]. Optics and Precision Engineering, 2017, 25(10): 2551-2563. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201710003

[8] Lan B, Wu X X, Li J F, et al. Influence of axial-force errors on the deformation of the 4 m lightweight mirror and its correction[J]. Applied Optics, 2017, 56(3): 611-619. doi: 10.1364/AO.56.000611

[9] Hu H F, Luo X, Liu Z Y, et al. Designing a hydraulic support system for large monolithic mirror's precise in-situ testing-polishing iteration[J]. Optics Express, 2019, 27(3): 3746-3760. doi: 10.1364/OE.27.003746

[10] 陈夫林, 张景旭, 吴小霞, 等.模态振型拟合薄镜面变形分析[J].红外与激光工程, 2011, 40(11): 2238-2243. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hwyjggc201111033

Chen F L, Zhang J X, Wu X X, et al. Deformation of thin primary mirror fitted with its vibration mode[J]. Infrared and Laser Engineering, 2011, 40(11): 2238-2243. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hwyjggc201111033

[11] Noethe L. Use of minimum-energy modes for modal-active optics corrections of thin meniscus mirrors[J]. Journal of Modern Optics, 1991, 38(6): 1043-1066. doi: 10.1080/09500349114551091

[12] 范磊, 乔兵, 王富国.薄镜面力矩校正在自由谐振模式下的定标计算[J].长春理工大学学报(自然科学版), 2016, 39(3): 9-13. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ccgxjmjxxyxb201603003

Fan L, Qiao B, Wang F G. Calibration of moment correction for thin mirror surface based on free harmonic vibration modal[J]. Journal of Changchun University of Science and Technology (Natural Science Edition), 2016, 39(3): 9-13. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ccgxjmjxxyxb201603003

[13] Nelson J E, Lubliner J, Mast T S. Telescope mirror supports: plate deflections on point supports[J]. Proceedings of SPIE, 1982, 332(12): 212-228. http://proceedings.spiedigitallibrary.org/mobile/proceeding.aspx?articleid=1233241

[14] 胡海飞, 赵宏伟, 刘振宇, 等. 4 m口径SiC反射镜原位检测用静压支撑系统[J].光学 精密工程, 2017, 25(10): 2607-2613. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201710010

Hu H F, Zhao H W, Liu Z Y, et al. Hydrostatic support system for in-situ optical testing of a 4 m aperture SiC mirror[J]. Optics and Precision Engineering, 2017, 25(10): 2607-2613. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201710010

[15] 王富国, 李宏壮, 杨飞.薄镜面主动光学对光学像差的校正能力分析[J].光子学报, 2010, 39(5): 871-875. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gzxb201005023

Wang F G, Li H Z, Yang F. Ability of the thin mirror active optics to correct optical astigmatio[J]. Acta Photonica Sinica, 2010, 39(5): 871-875. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gzxb201005023

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: