A highly sensitive cantilever temperature sensor for small-area heat source temperature measurement

-

摘要:

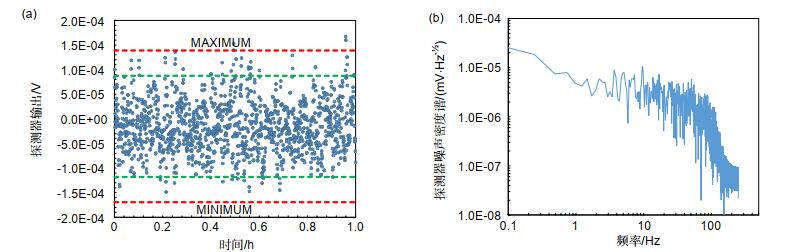

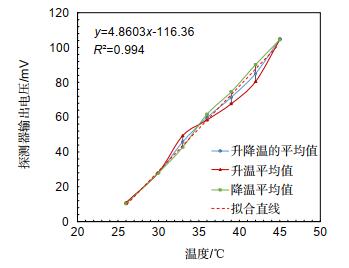

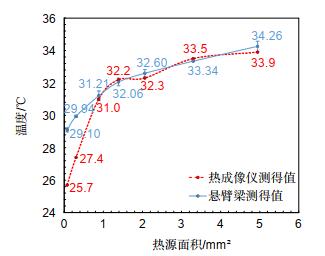

本文利用材料热膨胀系数不同的性质设计了一种可以对小面积热源进行高灵敏检测的温度传感器。该传感器的温度敏感元件是一个上表面镀有金属的氮化硅悬臂梁。由于金属与氮化硅的热膨胀系数不同,因此当悬臂梁所在的环境温度发生变化时,悬臂梁会向温度梯度变化快的方向发生弯曲,并且弯曲量与温度成正相关关系。实验中通过光杠杆测量梁的弯曲量,用标定的方式建立温度与探测器输出电压之间的关系。结果显示,该传感器的灵敏度可以达到4.86 mV/℃,以及0.04 ℃的温度分辨力。为验证传感器对小面积热源进行测量的适用性,我们利用NaYF4材料受激发热的性质,对不同面积热源产生的热量进行测量。结果显示,当发热面积约为0.07 mm2时依然可以进行准确测量,实现了对小面积热源温度进行精确测量的目的。

Abstract:

Abstract:In this paper, a kind of temperature sensor which can detect a small-area heat source with high sensitivity is designed by using the property of different thermal expansion coefficients of materials. The temperature sensitive element of the sensor is a silicon nitride cantilever beam which is coated with metal on its upper surface. Due to the difference of thermal expansion coefficients between the metal and silicon nitride, the cantilever beam will bend in the direction of rapid change of the temperature gradient, and the bending amount will be positively correlated with the temperature when the ambient temperature of the cantilever beam changes. In the experiment, the bending amount of the beam is measured by the optical lever, and the relationship between the temperature and the output voltage of the detector is established by calibration. The results show that the sensitivity of the sensor can reach 4.86 mV/℃ and the temperature resolution can reach 0.04 ℃. In order to verify the applicability of the sensor for measuring the small-area heat source, the heat generated by heat sources of different areas is measured depending on the calorific property of NaYF4 under laser excitation. The results show that it still can be measured even the heating area is only 0.07 mm2 and the accurate measurement for temperature of the small-area heat source can be realized.

-

Key words:

- temperature sensor /

- bi-material cantilever /

- thermal expansion /

- NaYF4

-

Overview: High-precision and high-sensitivity temperature sensors are indispensable tools for material processing and biological cell research. For example, the temperature generated from biochemical reactions is a crucial indicator in the research of drugs in cells. However, the drug produces less heat through biochemical reactions in cells, and the cell volume is limited. Furthermore, the existing temperature sensor can only give a rough temperature range when measuring a very small heat source, so the high-sensitivity and high-precision measurement purpose cannot be achieved. Therefore, it requires a method that can accurately measure small-area heat sources. A static temperature sensor of non-contact cantilever beam is designed to measure the temperature of small-area heat sources and simplify the system design. The temperature sensitive element of the sensor is a silicon nitride cantilever beam which is coated with metal on its upper surface. Due to the difference of thermal expansion coefficients between metal and silicon nitride, the cantilever beam will bend in the direction where the temperature gradient changes rapidly when the ambient temperature of the cantilever beam changes, and the bending amount is measured by optical lever. The relationship between the temperature and the output voltage of the detector can be established by converting the bending amount into electrical signals with the detector. Through the theoretical analysis, the result shows that the bending amount is positively correlated with the change of temperature. Under the laboratory conditions, the relationship between the detector output voltage and the standard temperature can be established as y = 4.8603x - 116.36 by calibration. The goodness of fit is greater than 0.99, the sensitivity is 4.86 mV/℃, and the temperature resolution is 0.04 ℃. To verify the applicability of this method for measuring small-area heat sources, we used the property of the NaYF4 material that can generate heat when excited by laser. We also set up heat sources with different areas and measure the heat generated by the heat source. The results show that it still can be measured even the heating area is only 0.07 mm2. Finally, we prove the correctness of the experimental results by analyzing the relationship between the spectrum of the excited emission of NaYF4 and temperature. Thereby, the purpose of accurately measuring the temperature of the small-area heat source is realized.

-

-

图 1 (a) 双材料悬臂梁结构示意图;(b)梁受热弯曲示意图。由于上下层材料的热膨胀系数存在差异,所以当温度发生变化时梁会产生一定幅度的弯曲

Figure 1. (a) Diagram of bi-material cantilever beam structure; (b) Diagram of beam bending under heating. Due to the difference in thermal expansion coefficient between metal and SiNx, the beam will bend when the temperature changes

-

[1] Grover W H, Bryan A K, Diez-silva M, et al. Measuring single-cell density[J]. Proceedings of the National Academy of Sciences of the United States of America, 2011, 108(27): 10992–10996. doi: 10.1073/pnas.1104651108

[2] Childs P R N, Greenwood J R, Long C A. Review of temperature measurement[J]. Review of Scientific Instruments, 2000, 71(8): 2959–2978. doi: 10.1063/1.1305516

[3] 王欢, 郑刚, 陈海滨, 等.调频连续波激光干涉光纤温度传感器[J].光电工程, 2019, 46(5): 180506. doi: 10.12086/oee.2019.180506

Wang H, Zheng G, Chen H B. Frequency-modulated continuous-wave laser interferometric optical fiber temperature sensor[J]. Opto-Electronic Engineering, 2019, 46(5): 180506. doi: 10.12086/oee.2019.180506

[4] Ba D X, Chen C, Fu C, et al. A high-performance and temperature-insensitive shape sensor based on DPP-BOTDA[J]. IEEE Photonics Journal, 2018, 10(1): 7100810. https://www.onacademic.com/detail/journal_1000040195794110_2854.html

[5] Toda M, Inomata N, Ono T, et al. Cantilever beam temperature sensors for biological applications[J]. IEEJ Transactions on Electrical and Electronic Engineering, 2017, 12(2): 153–160. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1002/tee.22360

[6] 哈尔滨工业大学.一种细胞温度测量系统: 中国, CN106768406B[P]. 2019-03-26.

Harbin Institute of Technology. A cell temperature measurement system: CN106768406B [P]. 2019-03-26.

http://cprs.patentstar.com.cn/Search/Detail?ANE=8DDA7AHA9EHDAEHA9GHF8GBA3CBA7ADA9FCD9ICE9BED8AHA [7] Tang B B, Collings S K, Xiao H, et al. Bi-material strip based temperature sensor design and optimization through thermo-mechanical multi-physics modeling[J]. International Journal of Smart and Nano Materials, 2019, 10(1): 1–10. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1080/19475411.2018.1526226

[8] Boisen A, Dohn S, Keller S S, et al. Cantilever-like micromechanical sensors[J]. Reports on Progress in Physics, 2011, 74(3): 036101. doi: 10.1088/0034-4885/74/3/036101

[9] Barnes J R, Stephenson R J, Woodburn C N, et al. A femtojoule calorimeter using micromechanical sensors[J]. Review of Scientific Instruments, 1994, 65(12): 3793–3798. doi: 10.1063/1.1144509

[10] Roark R J, Young W C. Formulas for stress and strain[J]. Journal of Applied Mechanics, 1976, 43(3): 522. http://d.old.wanfangdata.com.cn/OAPaper/oai_arXiv.org_1207.7021

[11] 吴宇, 刘晓旻, 杨国光.光杠杆纳米微位移测量系统中的信号处理[J].光电工程, 2007, 34(7): 30–34, 38. doi: 10.3969/j.issn.1003-501X.2007.07.007

Wu Y, Liu X M, Yang G G. Signal process in a novel system for nano-displacement measurement based on optical lever[J]. Opto-Electronic Engineering, 2007, 34(7): 30–34, 38. doi: 10.3969/j.issn.1003-501X.2007.07.007

[12] Fukuma T, Jarvis S P. Development of liquid-environment frequency modulation atomic force microscope with low noise deflection sensor for cantilevers of various dimensions[J]. Review of Scientific Instruments, 2006, 77(4): 043701. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=a1881370023a8aa79917e981be086d96

[13] 王嘉俊, 庞涛. NaYF4: Yb3+/Sm3+的水热合成及980nm激发下的光致发热[J].中国科学:化学, 2019, 49(2): 311–318. http://d.old.wanfangdata.com.cn/Periodical/wjclxb201702011

Wang J J, Pang T. Hydrothermal synthesis of NaYF4: Yb3+, Sm3+ and photo-thermal effect under 980 nm excitation[J]. Scientia Sinica Chimica, 2019, 49(2): 311–318. http://d.old.wanfangdata.com.cn/Periodical/wjclxb201702011

[14] Chu C L, Fan S H. A novel long-travel piezoelectric-driven linear nanopositioning stage[J]. Precision Engineering, 2006, 30(1): 85–95. doi: 10.1016/j.precisioneng.2005.05.002

[15] Boyer J C, Cuccia L A, Capobianco J A. Synthesis of colloidal upconverting NaYF4: Er3+/Yb3+ and Tm3+/Yb3+ monodisperse nanocrystals[J]. Nano Letters, 2007, 7(3): 847–852. https://pubs.acs.org/doi/abs/10.1021/nl070235%2B

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: