Design and error analysis of multi-spectral and multi-axis parallelism testing scheme

-

摘要:

模块化设计、多通道集成已成为当前光电装备研制的主流思路,但多个探测单元的光轴一致性却直接影响着光电装备的使用效能。现有方法难以兼顾多光谱、多光轴、高精度、大轴系跨度等多种光轴平行性检测需求,为此,本文提出了一种基于“反射式结构+光轴平移”思想的多光谱多光轴平行性检测方案。采用“反射式结构”设计反射式平行光管,解决了多光谱范围内可见光、微光、激光、红外等不同波段光轴的平行性检测问题;利用“光轴平移”思想解决了大跨度范围内光轴间平行性检测问题。结果表明:本设计方案的平行性检测误差小于0.134 mrad,可检测的轴系跨度可达0.5 m,能够满足绝大多数光电装备的光轴平行性检测需求。

Abstract:

Abstract:The modular design and multi-channel integration has become the main thought of developing the photoelectric equipment, and the multi-axis parallelism directly influences the equipment performance. The current methods cannot meet the actual testing needs of multi-spectral, multi-axis, high-precise and large axis space. Thus a multi-spectral and multi-axis parallelism testing scheme is put forward by adopting the designing thought of reflective type and optical axis translation. The reflective collimator is designed to solve the multi-spectral and multi-axis parallelism testing problems, and the optical axis translation design can increase the axis space of multi-axis parallelism test. The results show that the parallelism testing error is less than 0.134 mrad and the axis space can reach 0.5 m, which can satisfy parallelism testing needs of most photoelectric equipment.

-

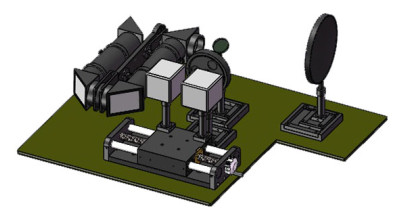

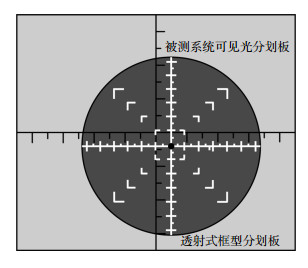

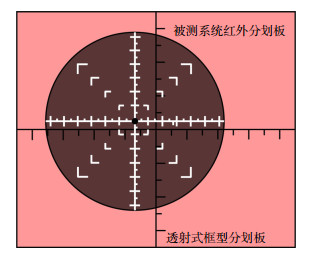

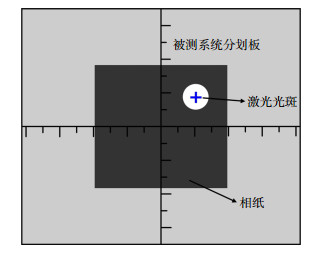

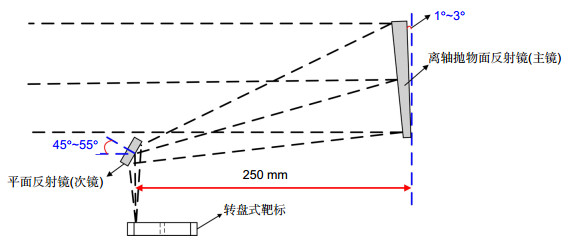

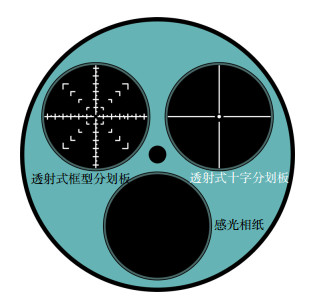

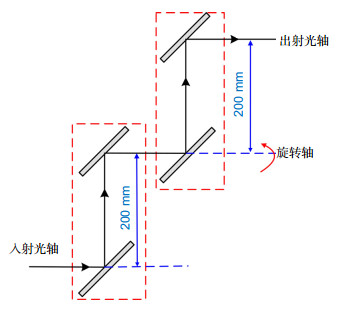

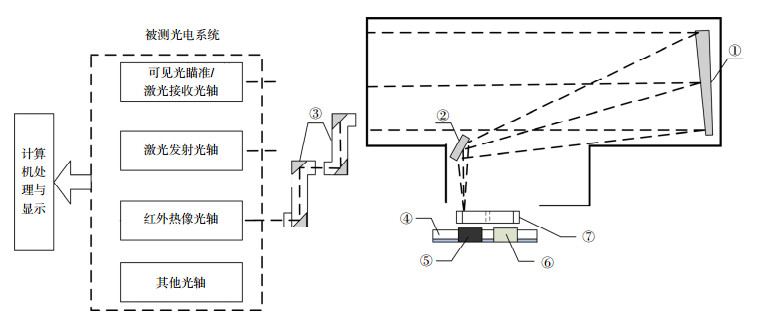

Overview: With the modernization of weapons and equipment, the military photoelectric equipment has been developed from traditional single-spectral and single-axis equipment to integrated photoelectric equipment with multi-spectral and multi-axis structure, which consists of laser ranging, laser guidance, photoelectric reconnaissance, and so on. The optical axis parallelism among multiple detection channels directly determines the precision of the integrated photoelectric equipment, and the target can be effectively located and tracked as long as each optical axis is parallel to each other. Nowadays, the common optical axis parallelism test methods include projection target plate method, laser collimator method, five prism method, large-diameter collimator method, and so on. However, the current methods cannot meet the actual testing needs of multi-spectral, multi-axis, high-precise and large axis space, and thus a parallelism testing scheme is put forward by adopting the designing thought of reflective type and optical axis translation. The proposed multi-spectral and multi-axis parallelism testing scheme is composed of off-axis parabolic reflective collimator, turntable target board, optical-axis translation device and lighting source. Since the transmission structure is different to be used to design the multi-spectral optical system and the problem of center occlusion exists in the coaxial reflective type, the off-axis parabolic reflective collimator is adopted to satisfy the multi-spectral parallelism tests, and the effective aperture and focal length of the designed collimator are 100 mm and 300 mm, respectively. The transmission hole structure is adopted in the design of the frame-type reticle and the cross reticle which can be used in infrared and visible light path, and the sensitive paper is selected to record the optical axis of laser channel. The optical-axis translation device is designed with two pairs of rhombic reflectors which can obtain higher translation precision, and this structure can also meet the test need of large axis space. Then, the axis parallelism tests are carried out aiming at several typical equipment including two visible binoculars, one binocular night vision viewer and one binocular infrared thermal imager. The validity of proposed scheme is proved through testing the above equipment status. Besides, the error analysis of parallelism test is carried out in detail from four aspects, including the collimator collimation error, optical-axis translation error, reticle error and laser axis error. The results show that the parallelism testing error is less than 0.134 mrad, and the axis space can reach 0.5 m, which can satisfy parallelism testing needs of most photoelectric equipment. At last, the performance comparison among the proposed scheme and other schemes is made from five aspects which are spectral region, testing precision, detectable distance, test environment and main shortcomings.

-

-

表 1 典型光电装备的光轴平行性检测结果

Table 1. The test results of optical axis parallelism of typical photoelectric equipment

水平平行性误差/(′) 垂轴平行性误差/(′) 可见光双目望远镜1(故障装备) 180.62 86.82 可见光双目望远镜2(新品装备) 4.02 6.57 双目微光观察镜(故障装备) 197.95 162.02 双目红外热像仪(故障装备) 79.13 51.94 表 2 本文方案与同类方案对比

Table 2. Performance comparison of different scheme

投影靶板法 激光光轴仪法 五棱镜法 大口径平行光管法 本文方法 光谱范围 多光谱 以可见光为主 以可见光为主 透射式:可见光

反射式:多光谱多光谱 检测精度 较高 决定于光轴仪精度 存在随机误差 较高 较高 可检测轴距 较大 较小 较大 较小 较大 环境要求 实验距离>100m 室内环境 室内环境 室内环境 室内、室外 不足之处 只能在夜晚或阴天进行 装调难度较大 棱镜平移时精度难以保证 大口径平行光管制作难度大 装调难度较大 -

[1] 陈志斌, 肖文健, 马东玺, 等.大间距多光轴一致性野外在线检测方法[J].光学学报, 2017, 37(1): 112006. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QKC20172017030600007920

Chen Z B, Xiao W J, Ma D X, et al. A method for large distance multi-optical axis parallelism online detection[J]. Acta Optica Sinica, 2017, 37(1): 112006. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QKC20172017030600007920

[2] 吉书鹏.机载光电载荷装备发展与关键技术[J].航空兵器, 2017(6): 3-12. http://d.old.wanfangdata.com.cn/Periodical/hkbq201706001

Ji S P. Equipment development of airborne electro-optic payload and its key technologies[J]. Aero Weaponry, 2017(6): 3-12. http://d.old.wanfangdata.com.cn/Periodical/hkbq201706001

[3] 贺和好, 叶露, 周兴义, 等.平行度测试仪原理及其测量精度分析[J].光电工程, 2007, 34(5): 52-56. doi: 10.3969/j.issn.1003-501X.2007.05.012

He H H, Ye L, Zhou X Y, et al. Theory and precision analysis of testing apparatus of parallel depth[J]. Opto-Electronic Engineering, 2007, 34(5): 52-56. doi: 10.3969/j.issn.1003-501X.2007.05.012

[4] 王鑫, 白素平, 许庭赫.远距多光轴平行度检测方法研究[J].长春理工大学学报(自然科学版), 2017, 40(6): 48-51. doi: 10.3969/j.issn.1672-9870.2017.06.011

Wang X, Bai S P, Xu T H. A method for large distance multi-optical axis parallelism measurement[J]. Journal of Changchun University of Science and Technology (Natural Science Edition), 2017, 40(6): 48-51. doi: 10.3969/j.issn.1672-9870.2017.06.011

[5] Xiao Z J, Guo X X, Xia Y, et al. Research on detection system of optical sights triaxial parallelism[J]. Optik - International Journal for Light and Electron Optics, 2014, 125(16): 4427-4430. doi: 10.1016/j.ijleo.2014.02.035

[6] 李建荣, 王志乾, 王春霞, 等.单轴光电系统视轴测量方法研究[J].光电工程, 2015, 42(11): 8-12. doi: 10.3969/j.issn.1003-501X.2015.11.002

Li J R, Wang Z Q, Wang C X, et al. Sight axis measuring of the single axis photoelectric measuring system[J]. Opto-Electronic Engineering, 2015, 42(11): 8-12. doi: 10.3969/j.issn.1003-501X.2015.11.002

[7] 王阳, 黄煜, 李占峰, 等.利用恒星对天文观测系统光轴平行性检校[J].红外与激光工程, 2017, 46(5): 124-129. http://d.old.wanfangdata.com.cn/Periodical/hwyjggc201705018

Wang Y, Huang Y, Li Z F, et al. Calibration of optical axis parallelism by using star for astronomical observation system[J]. Infrared and Laser Engineering, 2017, 46(5): 124-129. http://d.old.wanfangdata.com.cn/Periodical/hwyjggc201705018

[8] 闫宗群, 杨建昌, 谢志宏, 等.大尺度多光谱多光轴平行性检校系统[J].应用光学, 2016, 37(6): 823-828. http://d.old.wanfangdata.com.cn/Periodical/yygx201606007

Yan Z Q, Yang J C, Xie Z H, et al. Optical axis parallelism calibration system of large-scale multi-spectral multi-optical axis[J]. Journal of Applied Optics, 2016, 37(6): 823-828. http://d.old.wanfangdata.com.cn/Periodical/yygx201606007

[9] 左晓舟, 沈良吉, 杨海成, 等.折反式长波线阵红外传感器装调技术[J].光电工程, 2016, 43(5): 82-87. doi: 10.3969/j.issn.1003-501X.2016.05.014

Zuo X Z, Shen L J, Yang H C, et al. Alignment technology of catadioptric linear array LWIR sensor[J]. Opto-Electronic Engineering, 2016, 43(5): 82-87. doi: 10.3969/j.issn.1003-501X.2016.05.014

[10] 王永仲.鱼眼镜头光学[M].北京:科学出版社, 2006.

[11] 唐捷, 王文华, 洪善贤, 等.望远镜通用规范: GJB 1240-1991[S].北京: 国防科学技术工业委员会, 1992.

Tang J, Wang W H, Hong S X, et al. General specification for telescope: GJB 1240-1991[S]. Beijing: Commission on Science, Technology and Industry for National Defense, 1992.

[12] 李兴荣, 张志明, 李延峰, 等.微光夜视观察镜通用规范: GJB 5695-2006[S].北京: 中国人民解放军总装备部, 2006.

Li X R, Zhang Z M, Li Y F, et al. General specification for low light level observation scope: GJB 5695-2006[S]. Beijing: The General Armament Department of the PLA, 2006.

[13] 施亭侯, 任曦明, 张连顺, 等.军用光学仪器通用规范: GJB 369A-1998[S].北京: 国防科学技术工业委员会, 1998.

Shi T H, Ren X M, Zhang L S, et al. General specification for military optical instruments: GJB 369A-1998[S]. Beijing: Commission on Science, Technology and Industry for National Defense, 1998.

[14] 杨达钊, 刘庆新, 赵长祥, 等.光学侦察装备通用规范战术技术性能要求: GJBz 20420.2-97[S].北京: 中国人民解放军总参谋部, 1997.

Yang D Z, Liu Q X, Zhao C X, et al. General specifications for optical reconnaissance equipment tactical and technical performance: GJBz 20420.2-97[S]. Beijing: The General Staff of the Chinese People's Liberation Army, 1997.

[15] 蒋增红, 吴轩东, 徐榕, 等.军用光电测角仪通用规范: GJB 5231-2004[S].北京: 中国人民解放军总装备部, 2005.

Jiang Z H, Wu X D, Xu R, et al. General specification for military photoelectric goniometer: GJB 5231-2004[S]. Beijing: The General Armament Department of the PLA, 2005.

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: